Positioning and cooling device for perforating vertical plane

A technology of cooling device and vertical surface, applied in the direction of positioning measurement, drilling/drilling equipment, maintenance and safety accessories in boring machine/drilling machine, etc. There are no effective devices and other problems to achieve the effect of good cooling effect and large specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention is specifically described below in conjunction with accompanying drawing and embodiment:

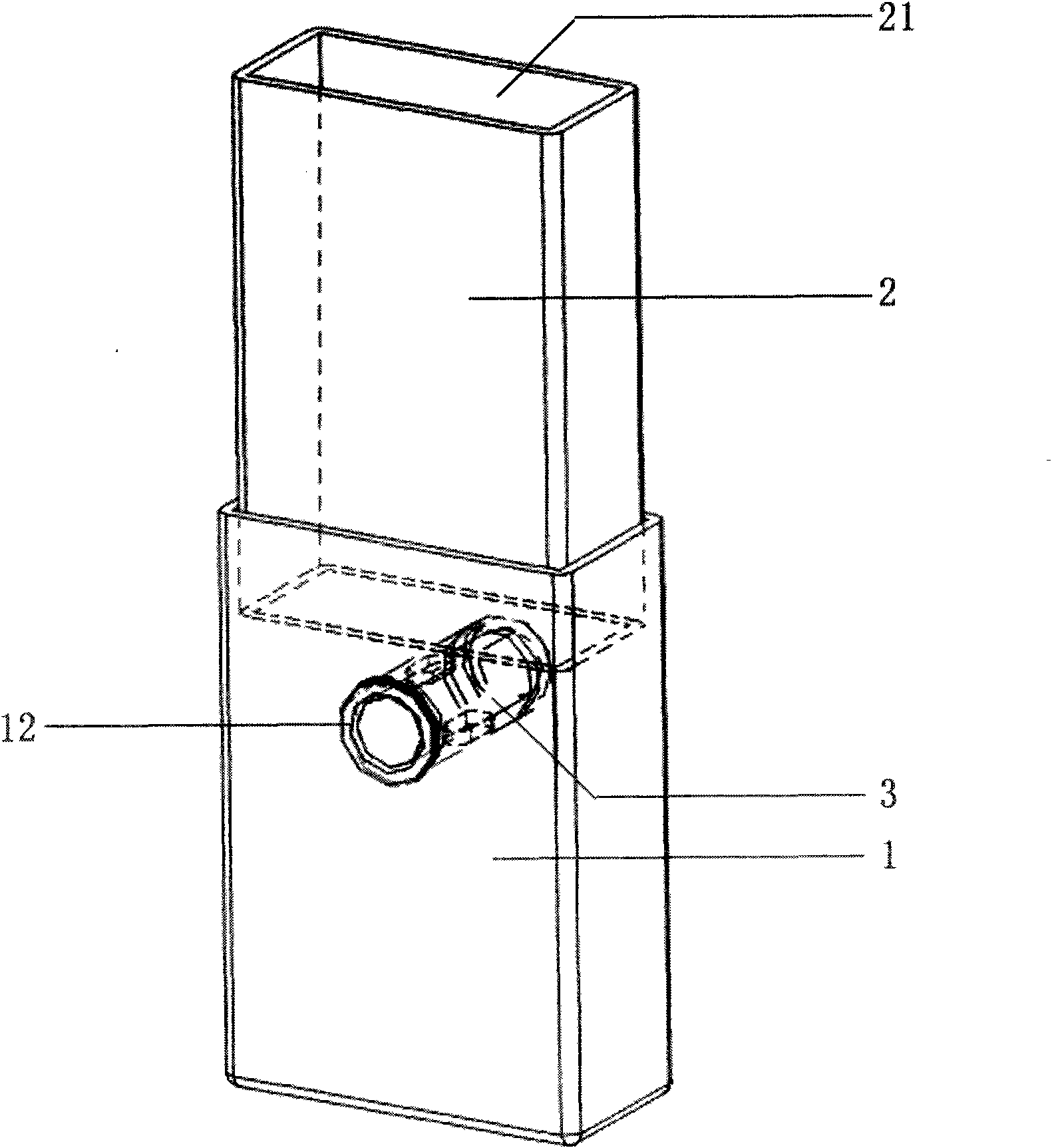

[0022] figure 1 The structure of the embodiment of the present invention is illustrated. The positioning cooling device for drilling vertical surfaces of the present invention is composed of a cup body 1, a cup body 2 2 and a drill sleeve 3, wherein the drill sleeve 3 is arranged on the cup 1, Material body two 2 is enclosed within in the cup body one 1.

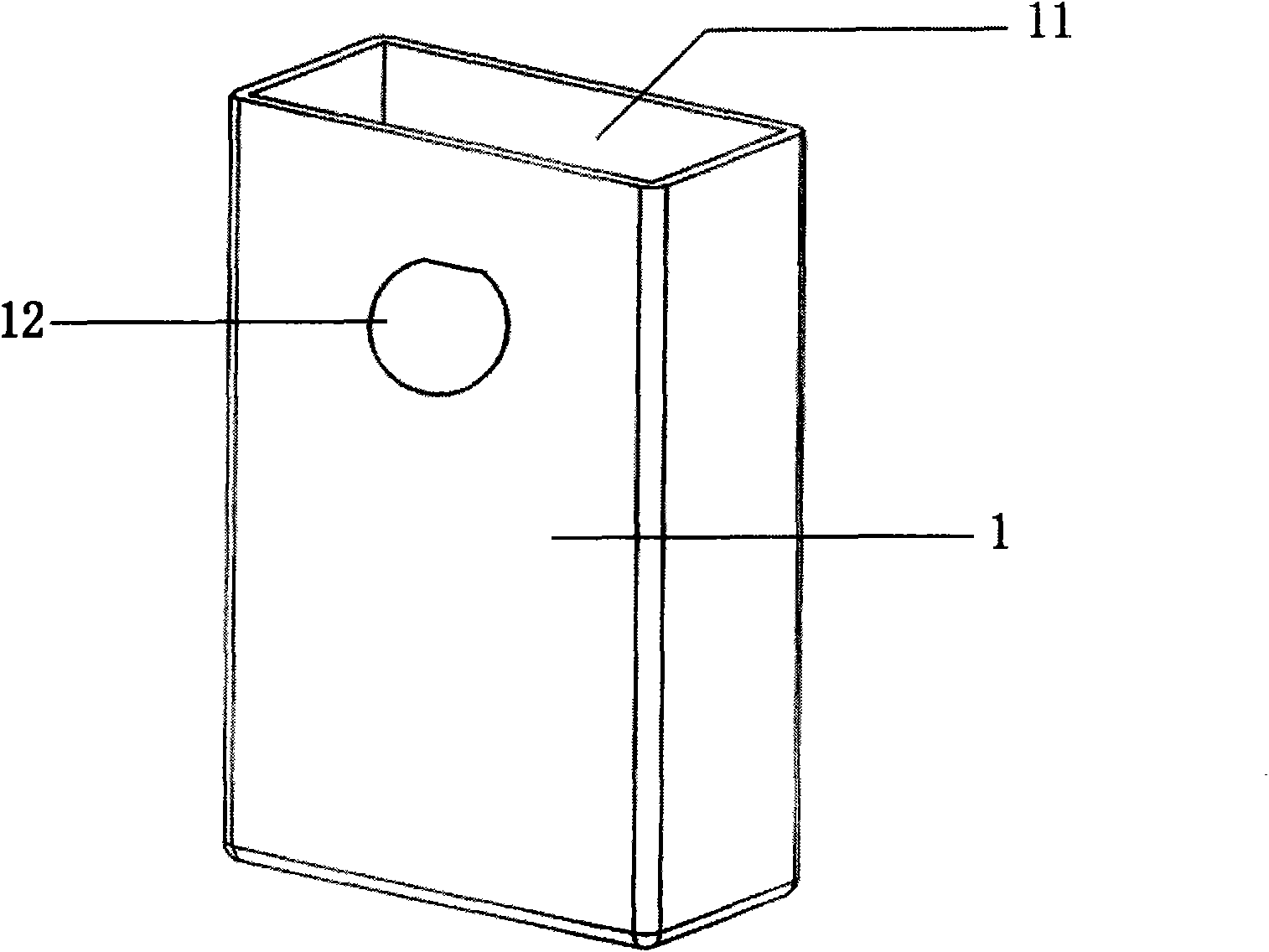

[0023] figure 2 The structure of the cup body-1 in the embodiment of the present invention is illustrated. The cup body-1 is in the shape of a cuboid, and an open end face 11 is provided at one end thereof. hole 12. The positioning hole 12 is arc-shaped, which is equivalent to the size of the drill sleeve 3, and the chord of the arc is parallel to the opening end face 11 of the cup body-1, and is arranged on one side close to the opening end face 11.

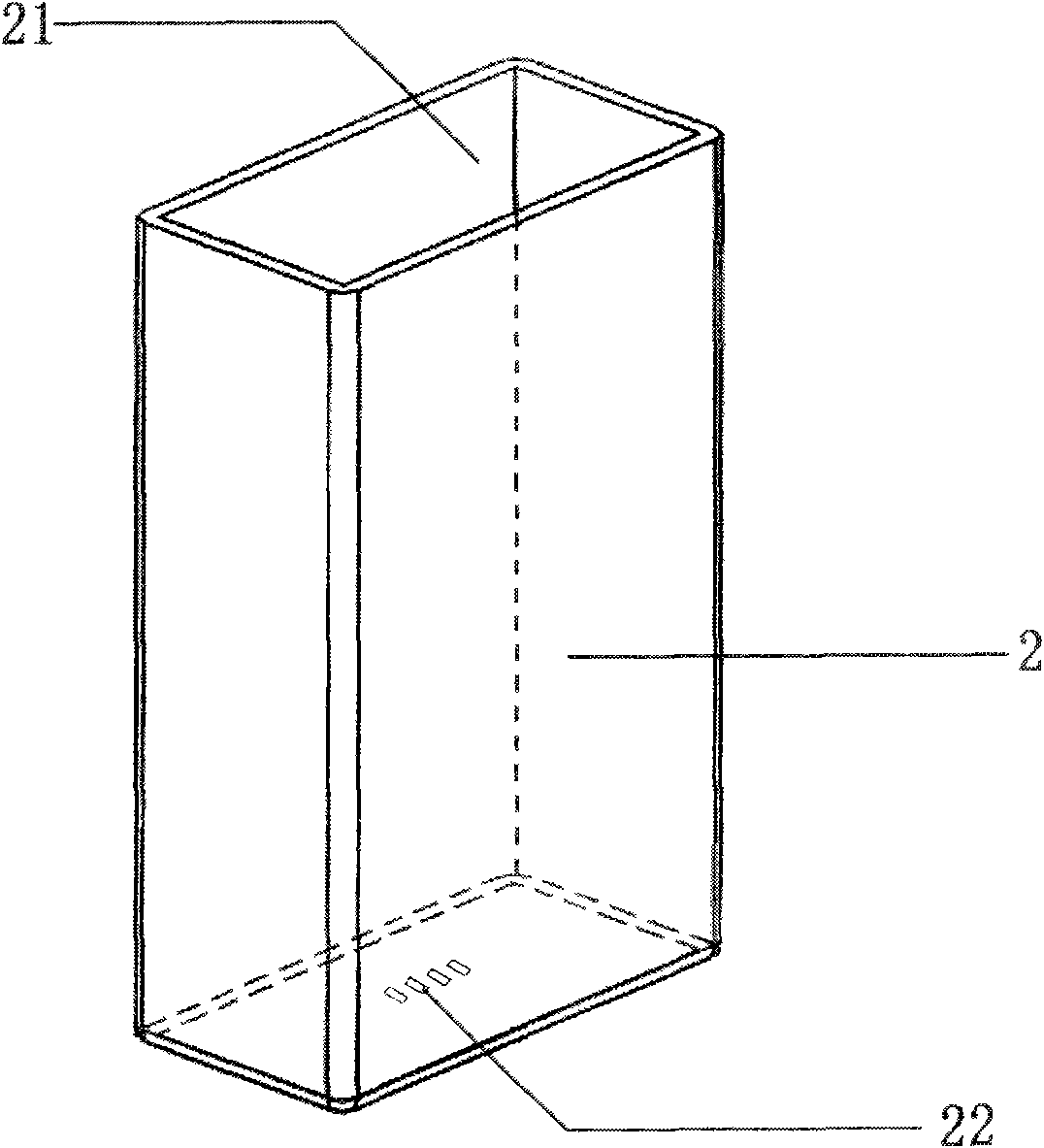

[0024] image 3 The struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com