Novel method for flocculating papermaking black liquor lignin

A technology for papermaking black liquor and lignin is applied in the field of selectively degrading lignin in straw pulp and selectively precipitating papermaking black liquor lignin. The effect of accelerating the cycle and reducing the investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Comparison of the effect of the flocculant formula used in the present invention and other formulas

[0018] The black liquor pulped with rice straw is the test water sample, and its original COD is 12000mg / L (COD is measured by potassium dichromate method). At room temperature, the above-mentioned black liquor was equally divided into 3 parts, each 100mL, the stirring speed was 50rpm / min, and potassium aluminum sulfate, ferrous sulfate, cationic polyacrylamide and chitin were added in sequence, so that the final concentrations of the above components were respectively 5%, 3%, 0.2% and 2%, adjust the pH value to 7.8, put it aside for 4 hours, take the supernatant to measure COD, the average COD is reduced to 327mg / L, and the COD removal rate is 97.3%. The other group used the same straw pulp raw material, added 0.1% polyaluminum chloride and 1% polyacrylamide, and aged for 4 hours according to the same pH and the same flocculation reaction time, the COD was 14...

Embodiment 2

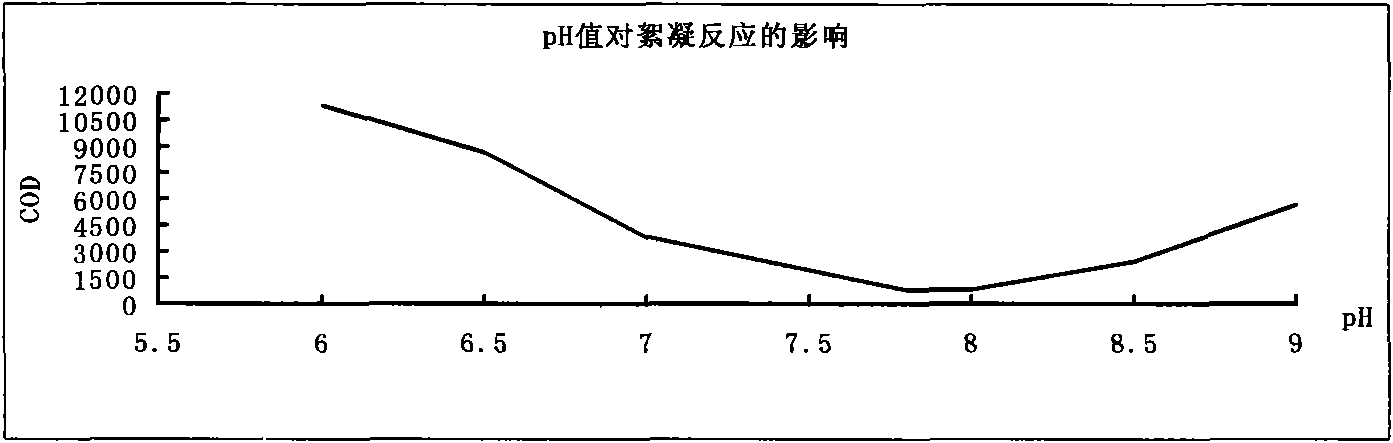

[0019] The influence of embodiment 2 different pH values on flocculation reaction

[0020] Take above-mentioned papermaking black liquor, stirring speed is 50rpm / min, add aluminum potassium sulfate, ferrous sulfate, cationic polyacrylamide and chitin successively, make the final concentration of above-mentioned composition be respectively 5%, 3%, 0.2% and 2%, flocculation was carried out under different pH conditions, the temperature of the water sample was room temperature, and after 6 hours of aging, the supernatant was taken to measure COD, and the test results were as follows figure 1 shown. As shown in the figure, pH has a great influence on the flocculation reaction, and the flocculation effect is the best when the pH is between 7.7 and 8.0, and the COD removal rate is about 95%.

Embodiment 3

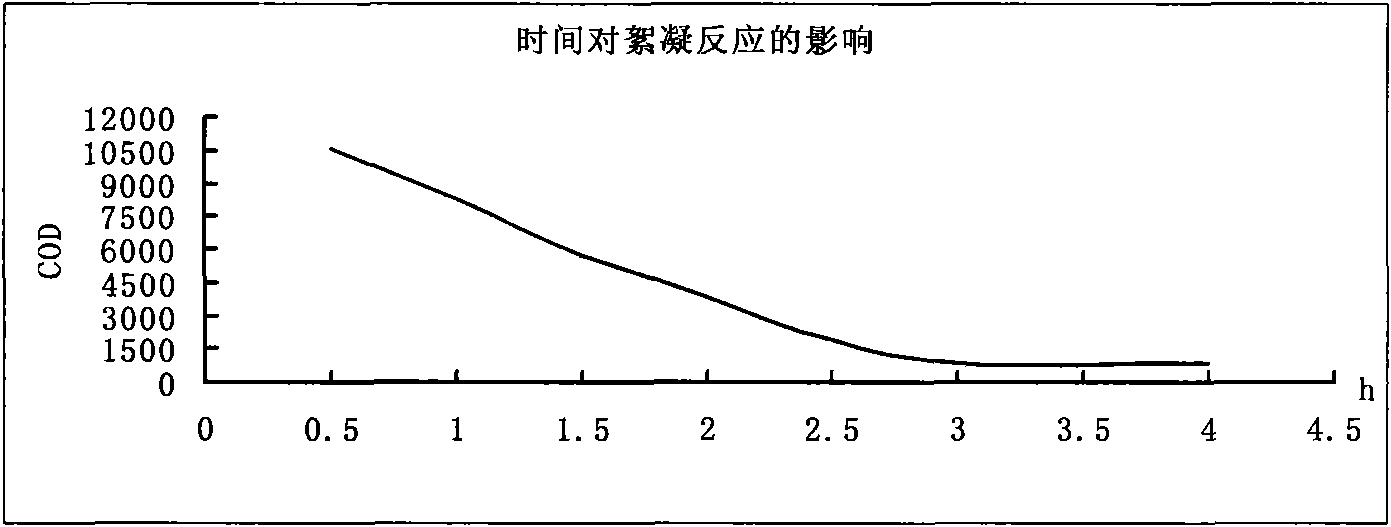

[0021] The influence of embodiment 3 flocculation time on flocculation reaction

[0022] Take above-mentioned papermaking black liquor, stirring speed is 50rpm / min, add aluminum potassium sulfate, ferrous sulfate, cationic polyacrylamide and chitin successively, make the final concentration of above-mentioned composition be respectively 5%, 3%, 0.2% and 2%, after adjusting the pH value to 7.8, take the supernatant to measure COD every hour, the test results are as follows figure 2 shown. As shown in the figure, the flocculation reaction is basically completed in about 3 hours, and the continued aging after 3 hours has little effect on reducing COD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com