Method and equipment for producing longitudinal multi-circle filter tip rod

A production method and filter rod technology, which are applied in e-liquid filter, application, tobacco and other directions, can solve the problems of inability to change the flow direction of smoke in the filter rod, non-layering, etc., achieve reasonable design, reduce harmful substances, The effect of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

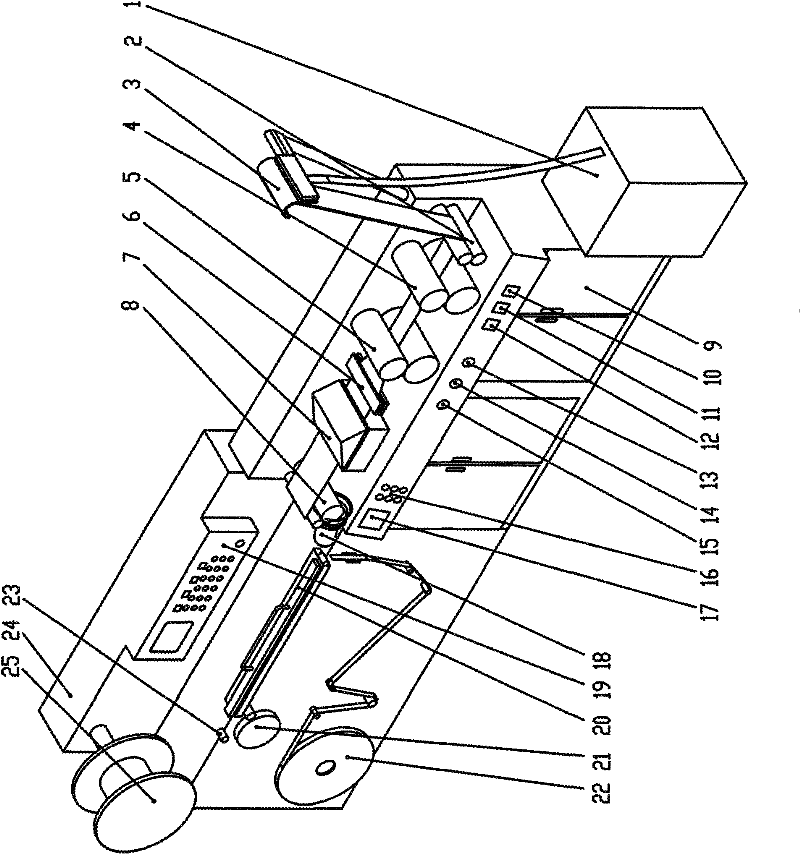

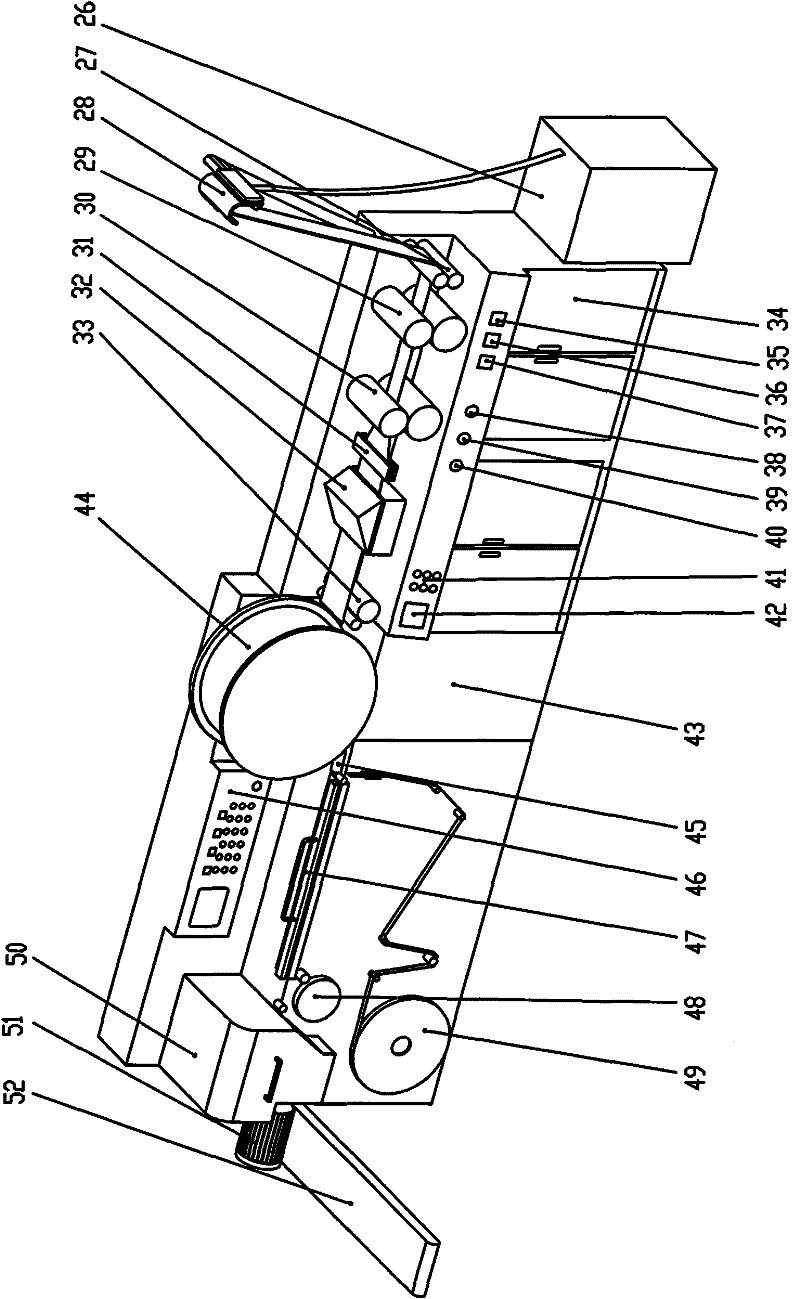

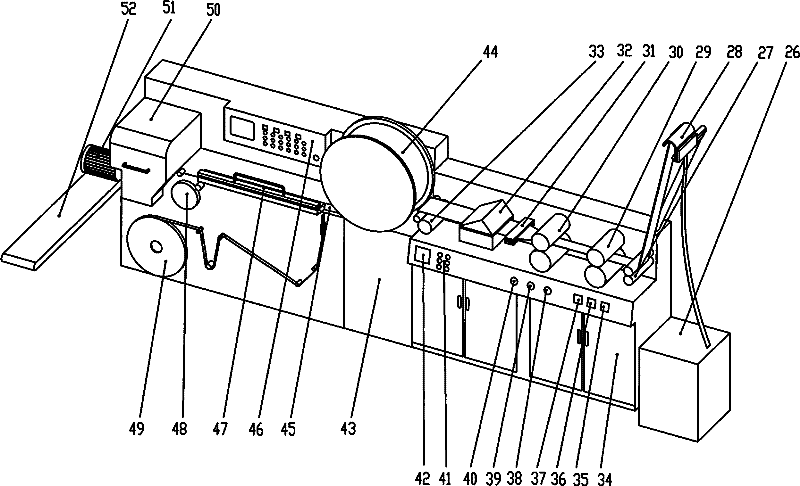

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. For the sake of simplicity, the method and equipment will be combined for description. as attached figure 1 And attached figure 2 Shown is the equipment of an embodiment of the present invention, and the schematic diagram of the front view of the main process flow. Produced in this embodiment is the longitudinal multi-circle filter rod that contains two layers of inner rod and outer circle. The figure includes the main process flow in the present invention. omitted in this figure. Different from the prior art, the equipment of the production method in this embodiment includes five parts: inner rod tow opening unit 9, inner rod collection and rewinding device 25, outer rod tow opening unit 34, inner rod unwinding device 43 and vertical multi-circle forming unit 46. In the present invention, the original equipment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com