Hardware constant power control circuit and electromagnetic induction heating device

A technology of constant power control and circuit, which is applied in the direction of induction heating, induction heating control, control/regulation system, etc. It can solve problems such as unreliable constant power control effect, long signal transmission and processing time, and transistor element burnout, etc., to avoid The effect of signal conversion process, shortening signal processing time, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

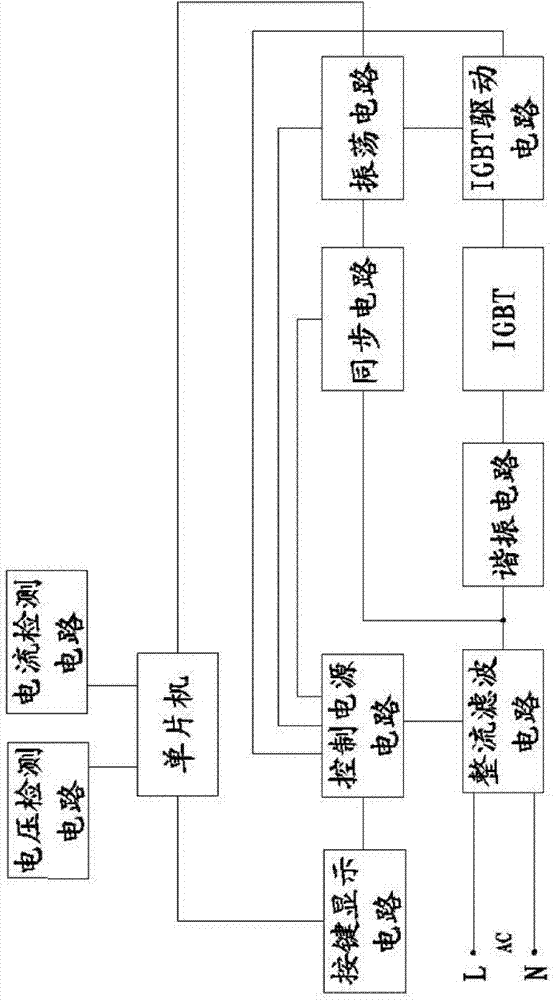

[0023] The structure and principle of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments, so as to understand the essence of the invention more intuitively.

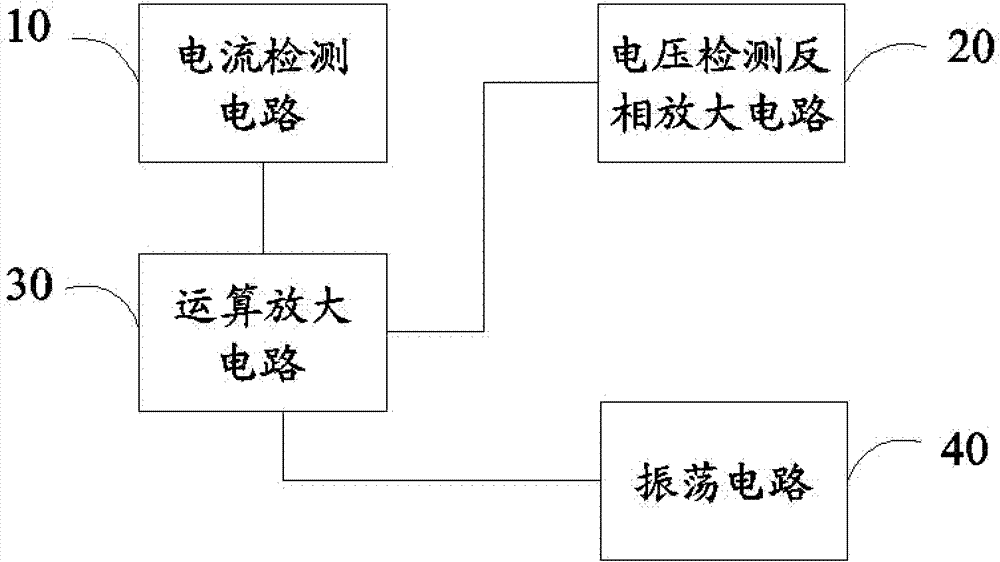

[0024] figure 2 It is a circuit block diagram of the hardware constant power control circuit in one embodiment of the present invention.

[0025] refer to figure 2 , the hardware constant power control circuit of the present invention comprises current detection circuit 10, voltage detection inverting amplifier circuit 20, operational amplifier circuit 30 and oscillation circuit 40, and current detection circuit 10 is connected with an input terminal of operational amplifier circuit 30; Voltage detection The input end of the inverting amplifier circuit 20 is connected with the main circuit, and the output end is connected with the other input end of the operational amplifier circuit; the output end of the operational amplifier circuit 30 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com