Novel direct-current motor

A DC motor, a new type of technology, applied in electrical components, electromechanical devices, etc., can solve the problems of easy wear and tear of carbon brushes, easy generation of sparks, and high motor prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

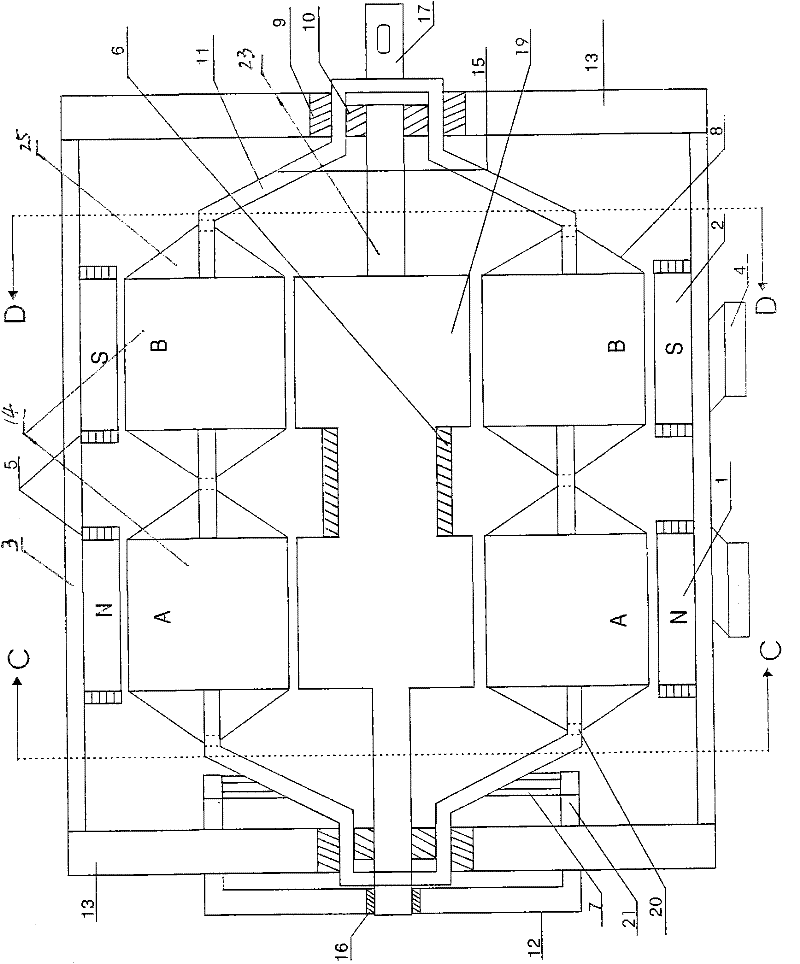

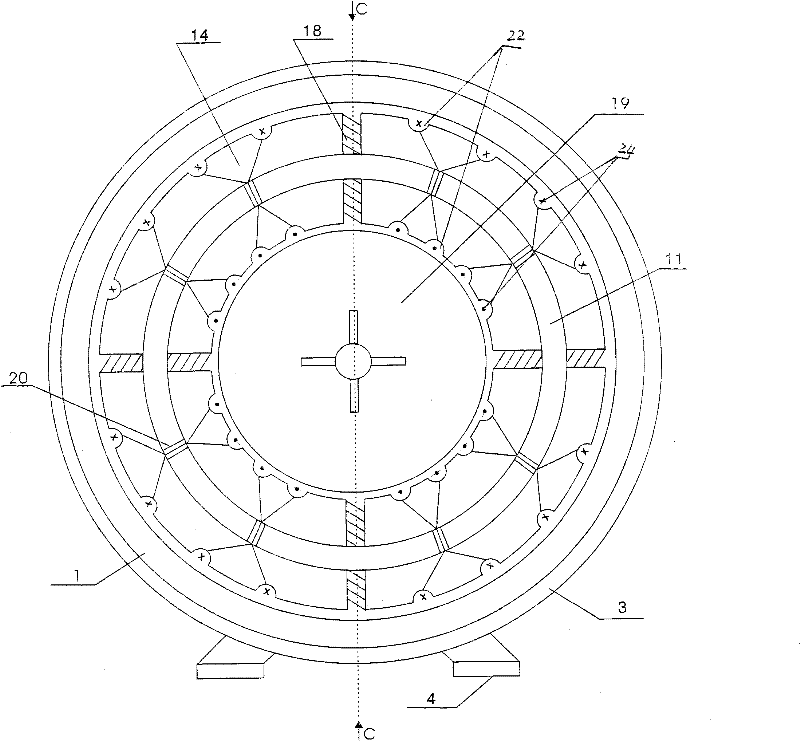

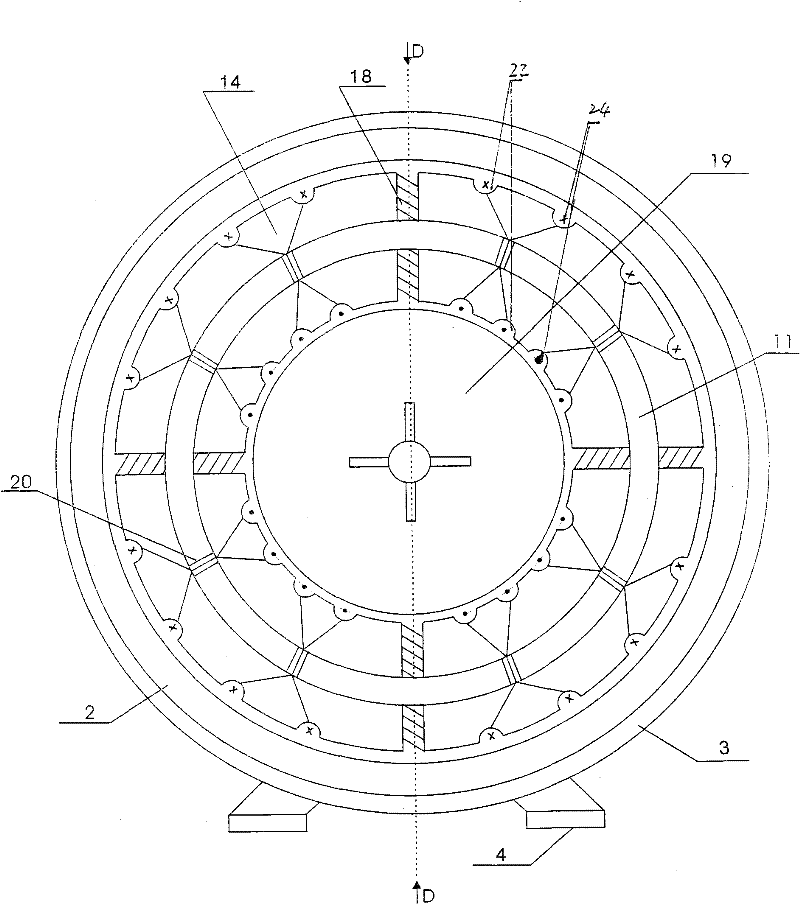

[0014] like figure 1 , figure 2 and image 3 As shown, the stepless direct current motor of the present utility model comprises cylindrical housing 3, and the two ends of housing 3 are end caps 13, and the inner wall of motor housing 3 is fixed with two annular stators, and the annular stators are separated by a certain distance, and the distance depends on the size of the motor power and The heat dissipation conditions of the coil are determined, and the distance between the two ring stators of the motor with high power is also large. There is a stator field winding 5 on each annular stator, and the two stator field windings 5 are N-pole annular stator 1 and S-pole annular stator 2 respectively. There is a central shaft 23 in the center of the motor casing 3, and there are two central shafts 23 The same cylindrical iron core has a central stator concentrated excitation winding 6 on the central axis 23 between the two iron cores to form a central stator 19. The positions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com