LCD (Liquid Crystal Display) panel

A liquid crystal display panel and display area technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of liquid crystal display panel quality degradation, scrapping, etc., to improve display quality, delay contact time, increase process and production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

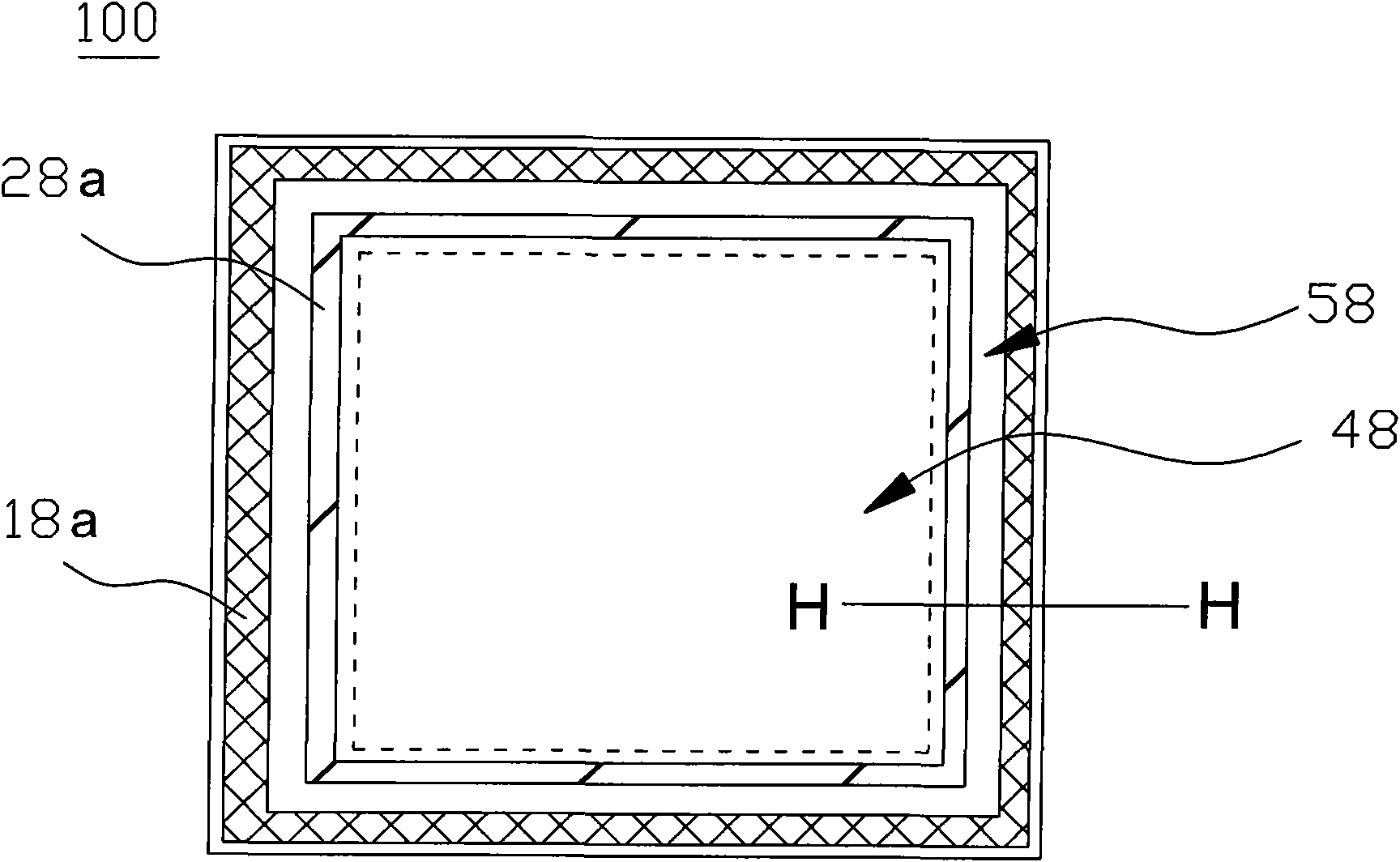

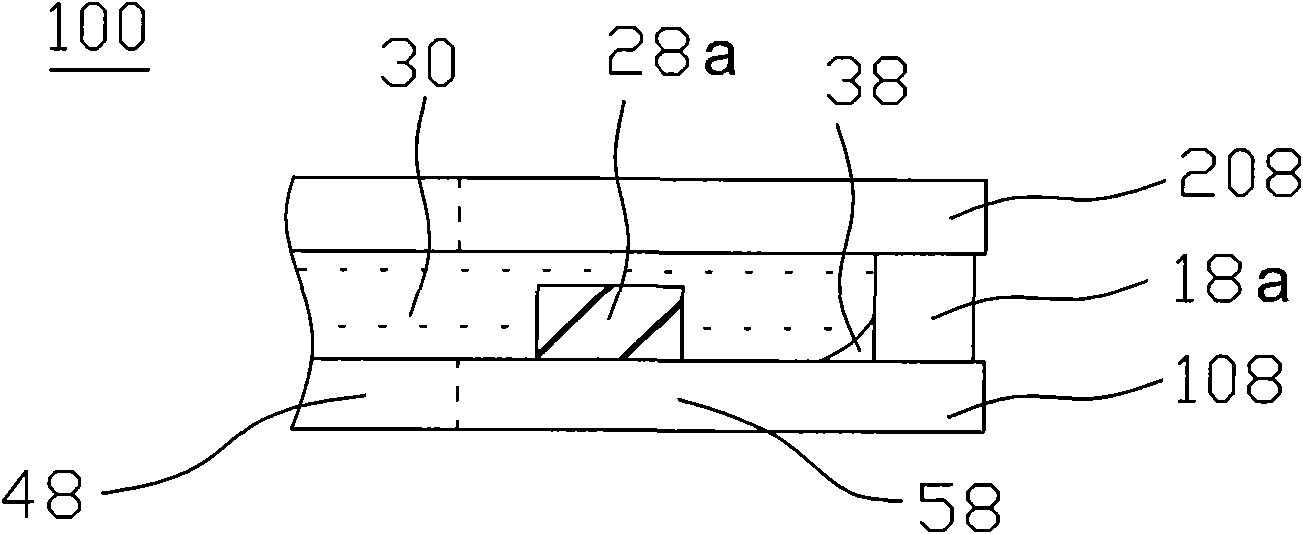

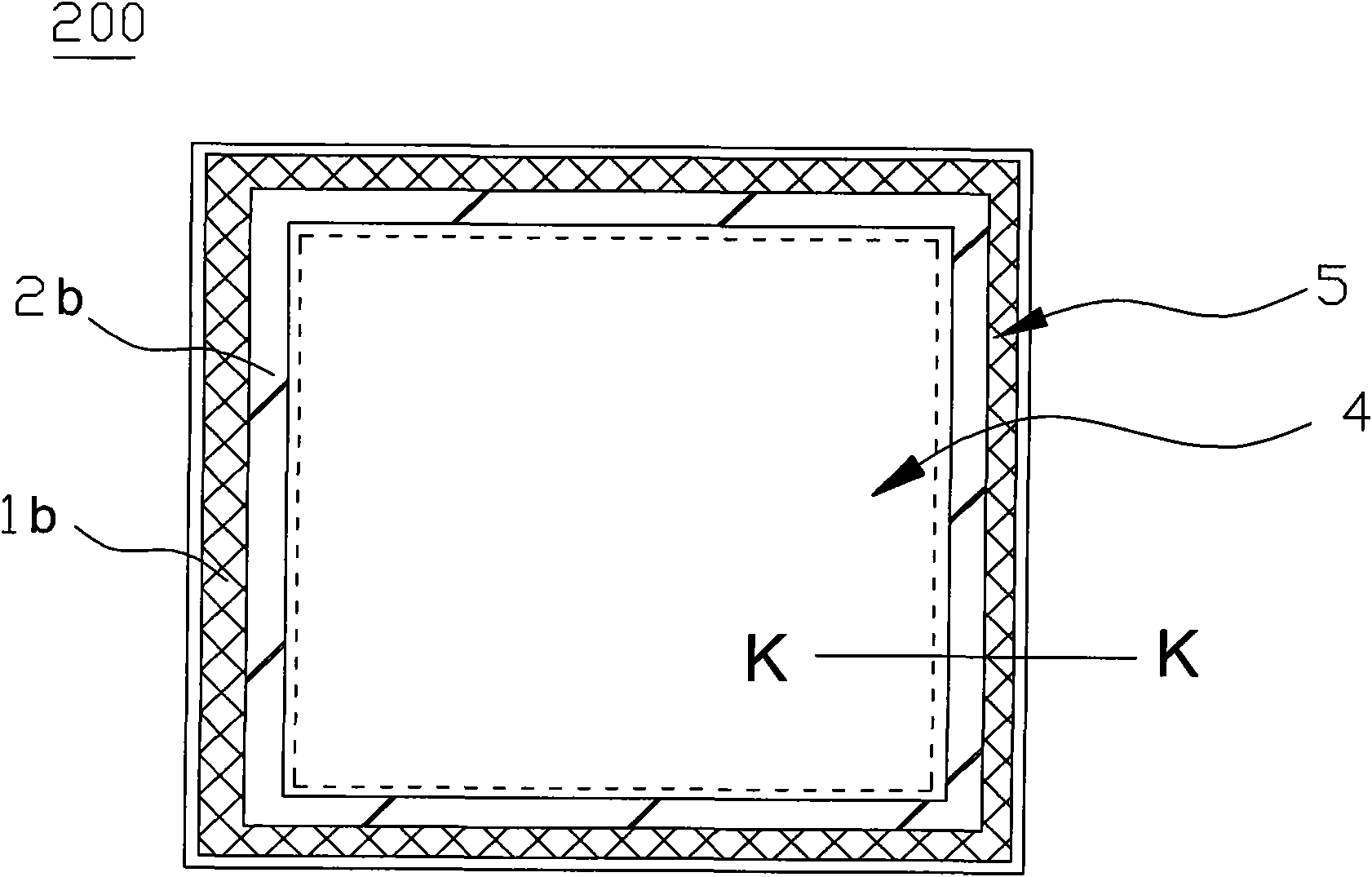

[0026] Please also refer to image 3 and Figure 4 , image 3 is a schematic diagram of a liquid crystal display panel of the present invention, Figure 4 Yes image 3 Sectional view along line KK. As shown in the figure, this specific embodiment provides a liquid crystal display panel 200 , and the liquid crystal display panel 200 includes a first substrate 10 , a second substrate 20 , a retaining wall 2 b , a sealant 1 b and a liquid crystal layer 30 . The second substrate 20 is disposed opposite to the first substrate 10 , and the first substrate 10 and the second substrate 20 have a common display area 4 and a non-display area 5 . The blocking wall 2 b is disposed on the first substrate 10 , and the blocking wall 2 b surrounds the display area 4 and is located in the non-display area 5 . There is a distance G between the retaining wall 2b and the second substrate 20, and the distance G is convenient to reduce the error accuracy of manufacturing the retaining wall 2b i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com