Fiber pressure sensing device based on C-shaped spring tube

The technology of a sensing device and a spring tube, applied in the field of devices, can solve the problems affecting the long-term use accuracy of the optical fiber sensing device, limiting the practicality and promotion of the sensor, limiting the practical application and the application range, etc., and achieves flexible use mode and simple structure. , the effect of extending the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

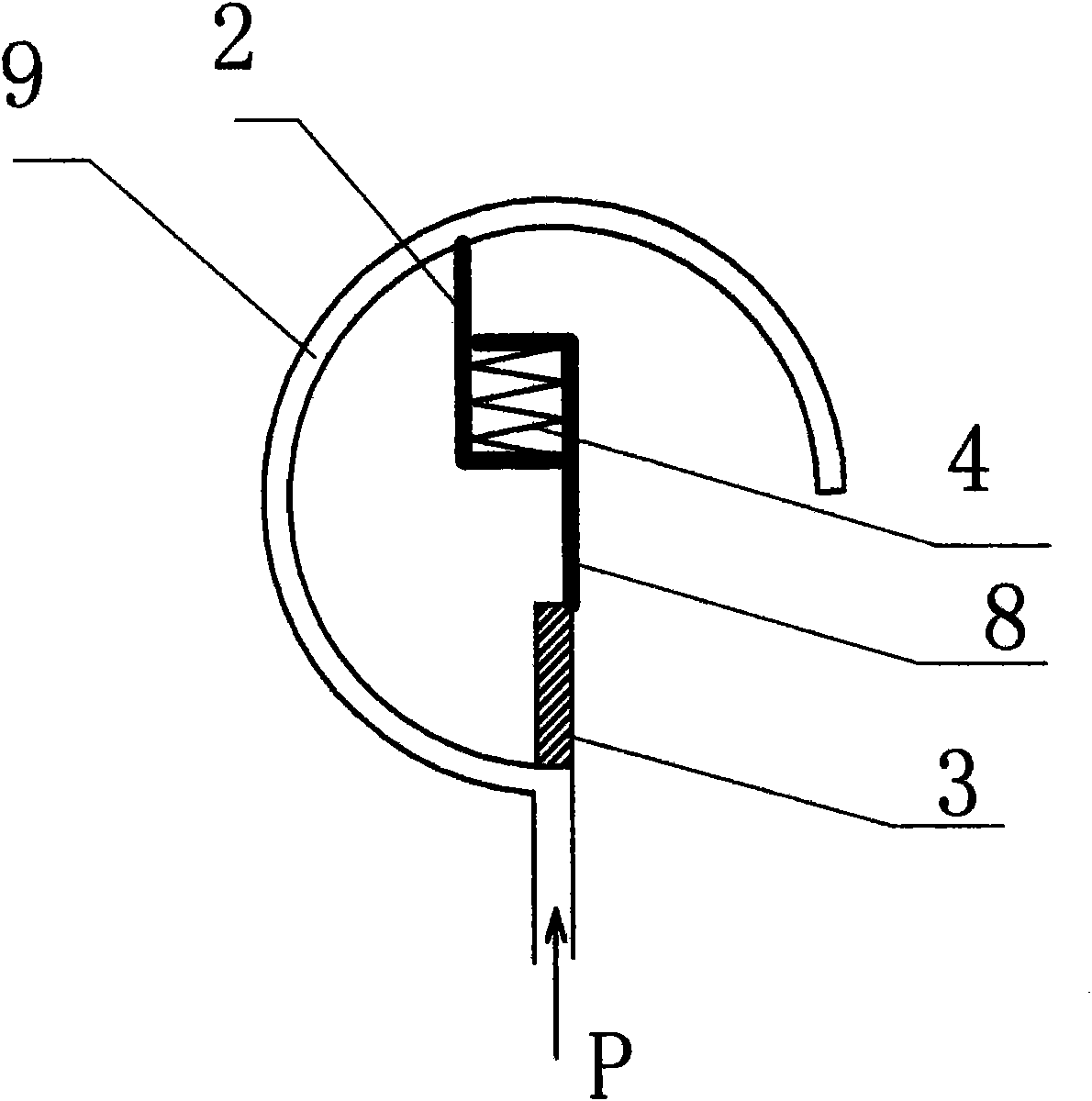

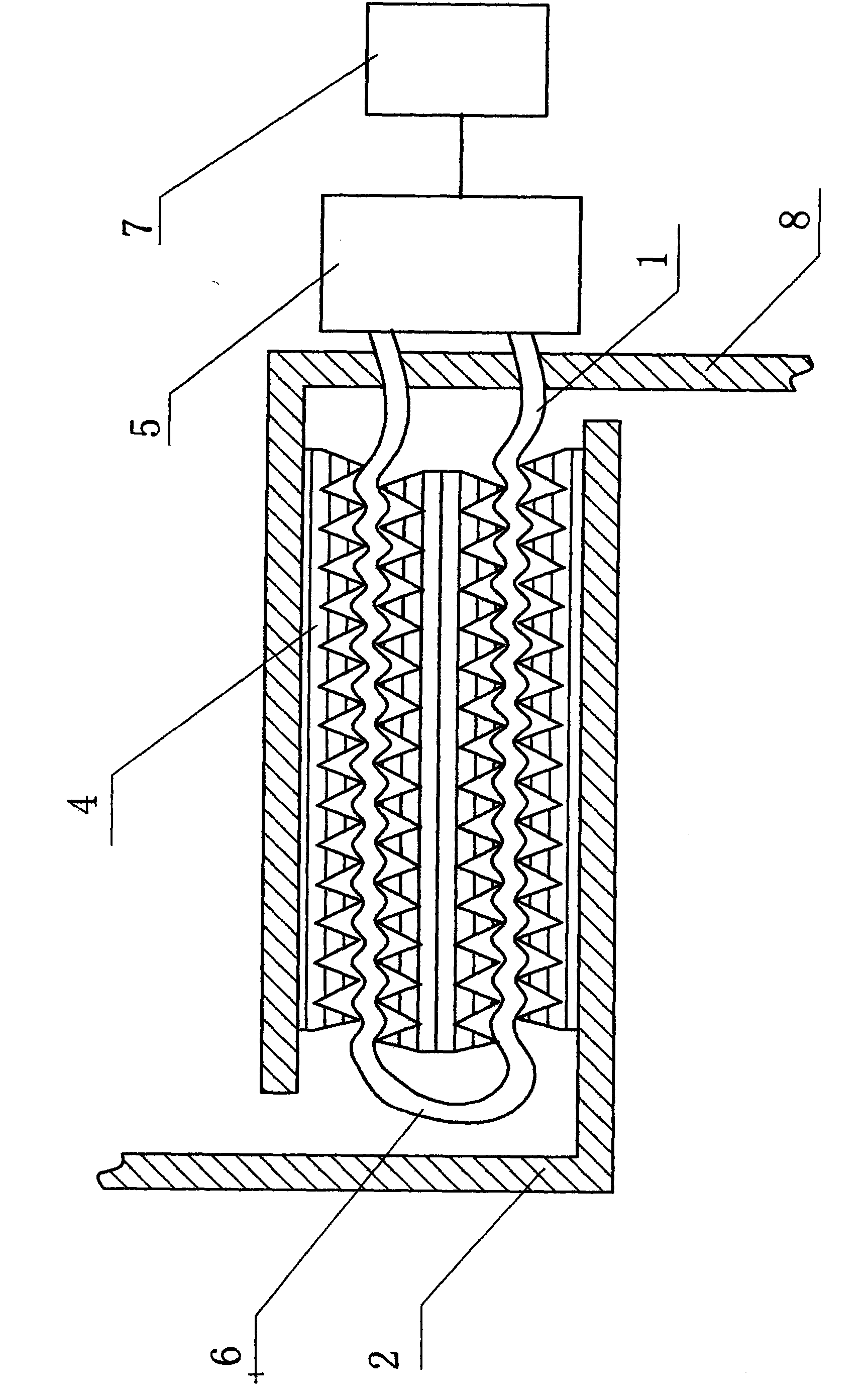

[0029] Such as figure 1 , figure 2 As shown, in the present invention, two ends of a multi-layer microbending element 4 including a signal optical fiber 6 are respectively installed on a C-shaped spring tube 9 and a fixing bracket 3 through a clamp 2 and a clamp 8 . The signal optical fiber 6 is connected to the test unit 5 through the extension optical fiber 1, and the processing unit 7 is connected behind the test unit 5. The change of the bending curvature of the signal optical fiber 6 will cause the change of the optical signal transmitted inside the signal optical fiber 6. After passing through the test unit 5 The change of the optical signal can be monitored and processed by the processing unit 7 . When the measured pressure P passes into the C-shaped spring tube 9, the C-shaped spring tube 9 tends to become round and straighten, and the straightening displacement of the C-shaped spring tube 9 drives the clamp 2, so that the position between the clamp 2 and the clamp 8...

Embodiment 2

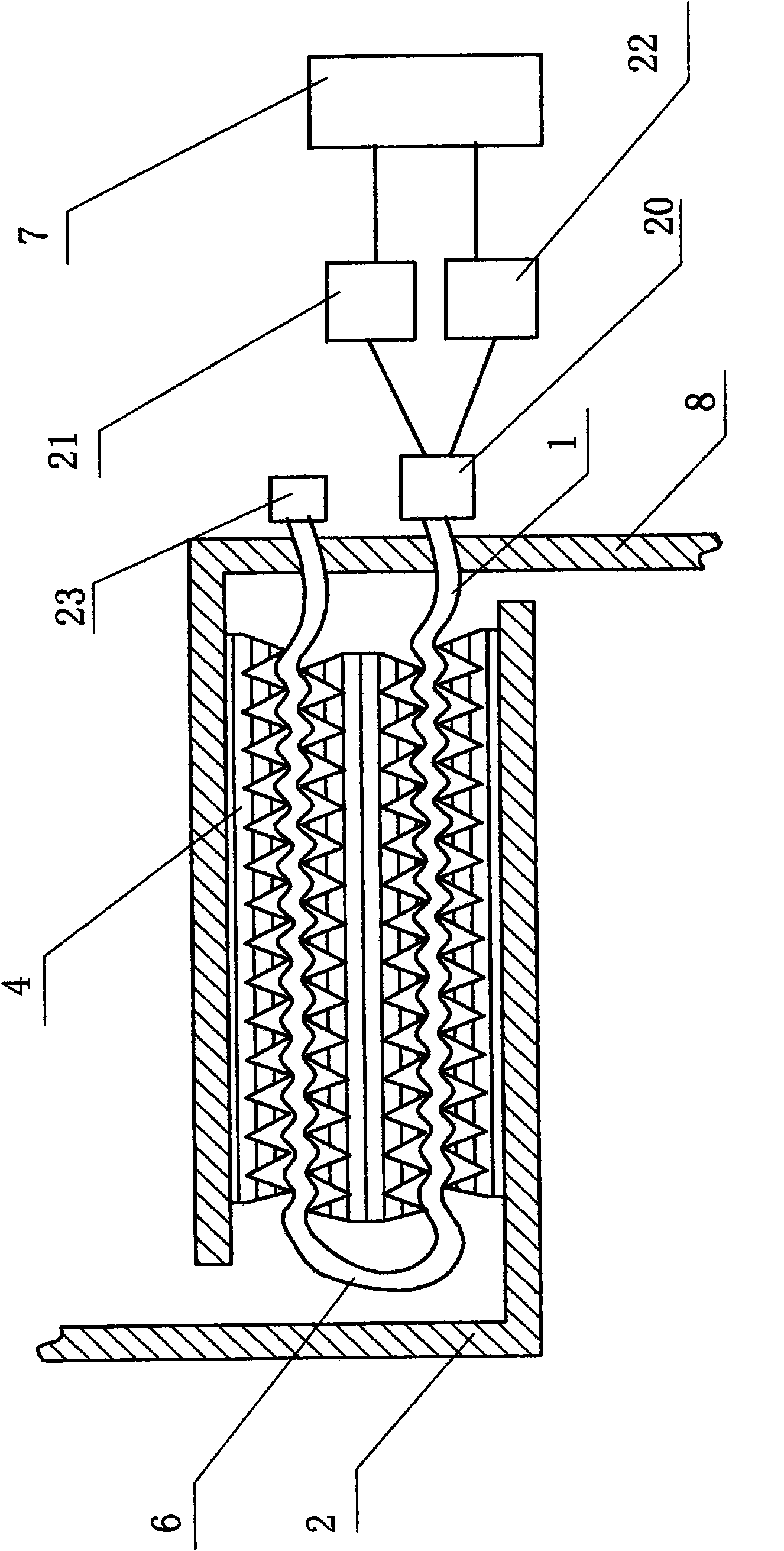

[0034] Such as image 3 As shown, in this embodiment, the difference from Embodiment 1 is: a light reflector 23 is arranged at one end of the signal fiber 6, the other end of the signal fiber 6 is connected to the extension fiber 1, and the extension fiber 1 is connected to a 1X2 optical branch Device 20, 2 ends of 1X2 optical splitter 20 are respectively connected with stable light source 21 and photodetector 22, and stable light source 21 and photodetector 22 are connected with processing unit 7 again, can make the optical signal transmitted in signal optical fiber 6 pass through twice like this The bent portion of the signal optical fiber 6 further improves the accuracy and sensitivity of the detection device. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0036] Such as Figure 4 As shown, in this embodiment, the difference from Embodiment 1 is that the multi-layer microbending element 4 is composed of a helical microbending element with two rows of deformed teeth corresponding to each other, and the gap between the two rows of deformed teeth is A signal optical fiber 6 is clamped. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com