Double screw propulsion device for plugging tools

A propulsion device, double-helix technology, applied in the direction of pipes/pipe joints/pipe fittings, mechanical equipment, pipe components, etc., can solve the problem of time-consuming pressure application process, and achieve the effect of speeding up the plugging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

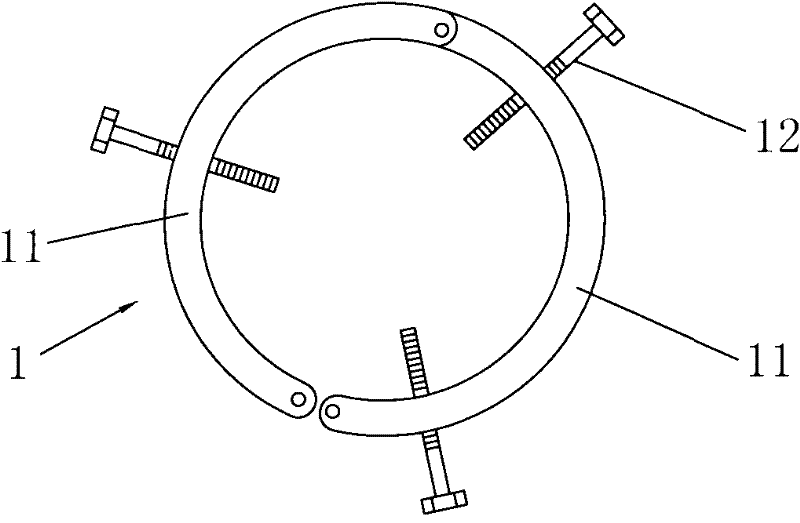

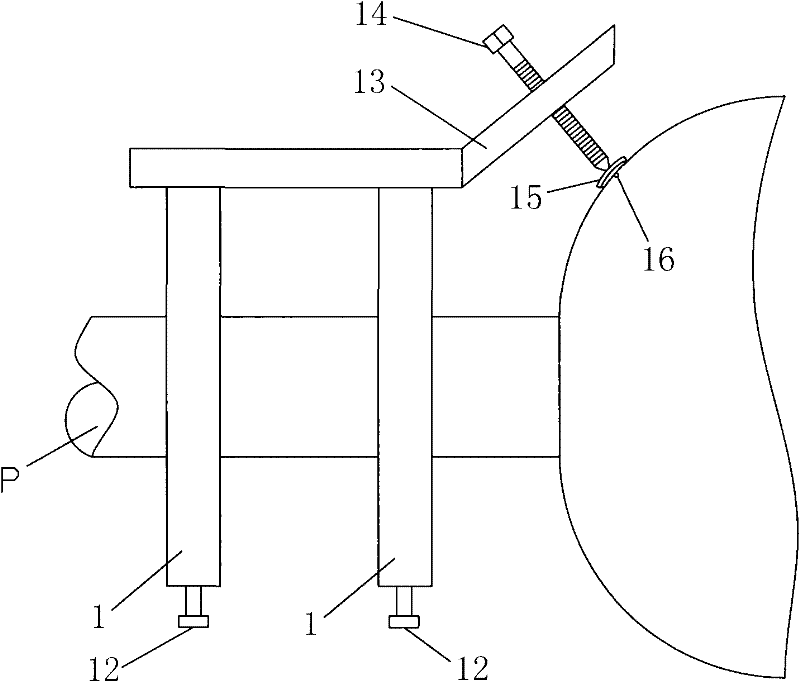

[0024] Such as Figure 5 , Image 6 As shown, it is a schematic diagram of the overall structure of the present invention used on the Haffle ring, corresponding to the two states of contraction and extension of the double helical propulsion device of the Haffle ring. It can be seen from the figure that the Haffle ring is a ring 2 composed of two half-rings 11, and three double-screw propulsion devices 3 are evenly distributed on the ring 2.

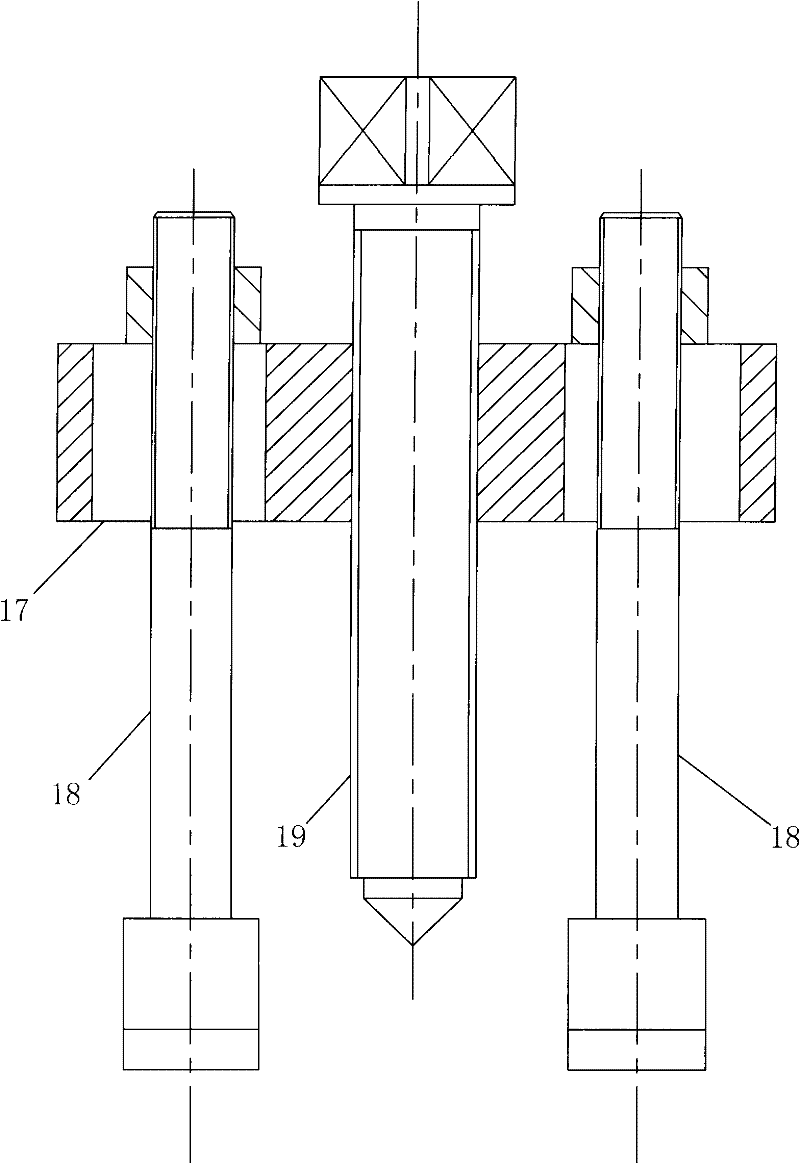

[0025] As for the specific structure of the described twin-screw propulsion device 3, please refer to Figure 7 As shown, it includes a rotating member 31 , a pressing member 32 and an anti-twist member 33 . The rotating part 31 is screwed on the ring part 2 through the first thread pair 311, and the end of the rotating part 31 protruding from the outer side of the ring part 2 is the twisting end 312, and the end extending into the inner side of the ring part 2 is then The second thread pair 313 is screwed to the pressing member 32 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com