Self-adaptive marching fixing device for vehicle-mounted suspension arm

A technology of fixing device and truck-mounted crane, which is applied to cranes and other directions to save fastening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

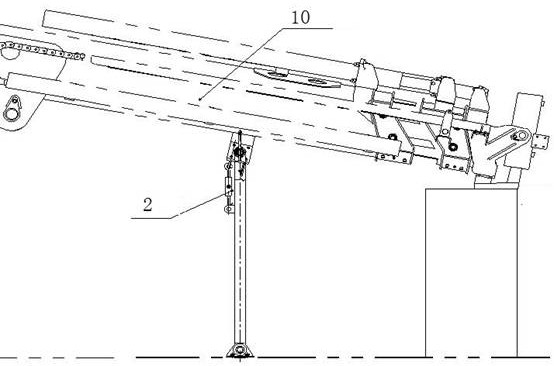

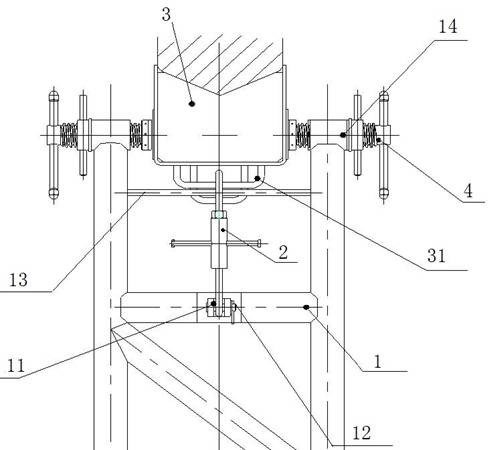

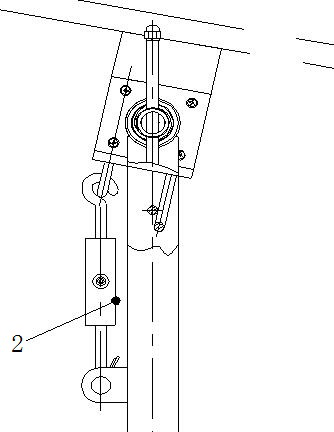

[0025] As shown in the figure, a fixed seat 3 is installed under the truck-mounted boom 10, and the fixed seat 3 is clamped between the two screw rods 4 at the upper end of the fixed frame 1, and the pull ring 31 at the bottom of the fixed seat 3 is connected and fixed by the tensioner 2. Crossbar on rack 1. The fixed frame 1 is a triangular truss structure composed of two columns, two cross bars and two oblique bars. The bottoms of the two columns are hinged on the vehicle body, and two lugs 11 are installed on the uppermost cross bar. A shaft pin assembly 12 is installed on the lug 11, a stop rod 13 is located on the top of the fixed frame 1, and the stop rod 13 is located between the pull ring 31 and the stop ring 32 at the bottom of the fixed seat 3, and the stop rod 13 can block the stop ring 32 prevent it from turning further. There are screw sleeves 14 on the top of the two columns for installing the screw rod 4. The screw rod 4 includes a screw rod 42 and a top plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com