Process for manufacturing medical operating table cloth

A technique of operating tablecloth and manufacturing process, which is applied in the direction of surgery, application, medical science, etc. It can solve the problems of increasing equipment investment, increasing space, increasing time, personnel, and energy loss, etc., and achieves the goal of increasing equipment investment and increasing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

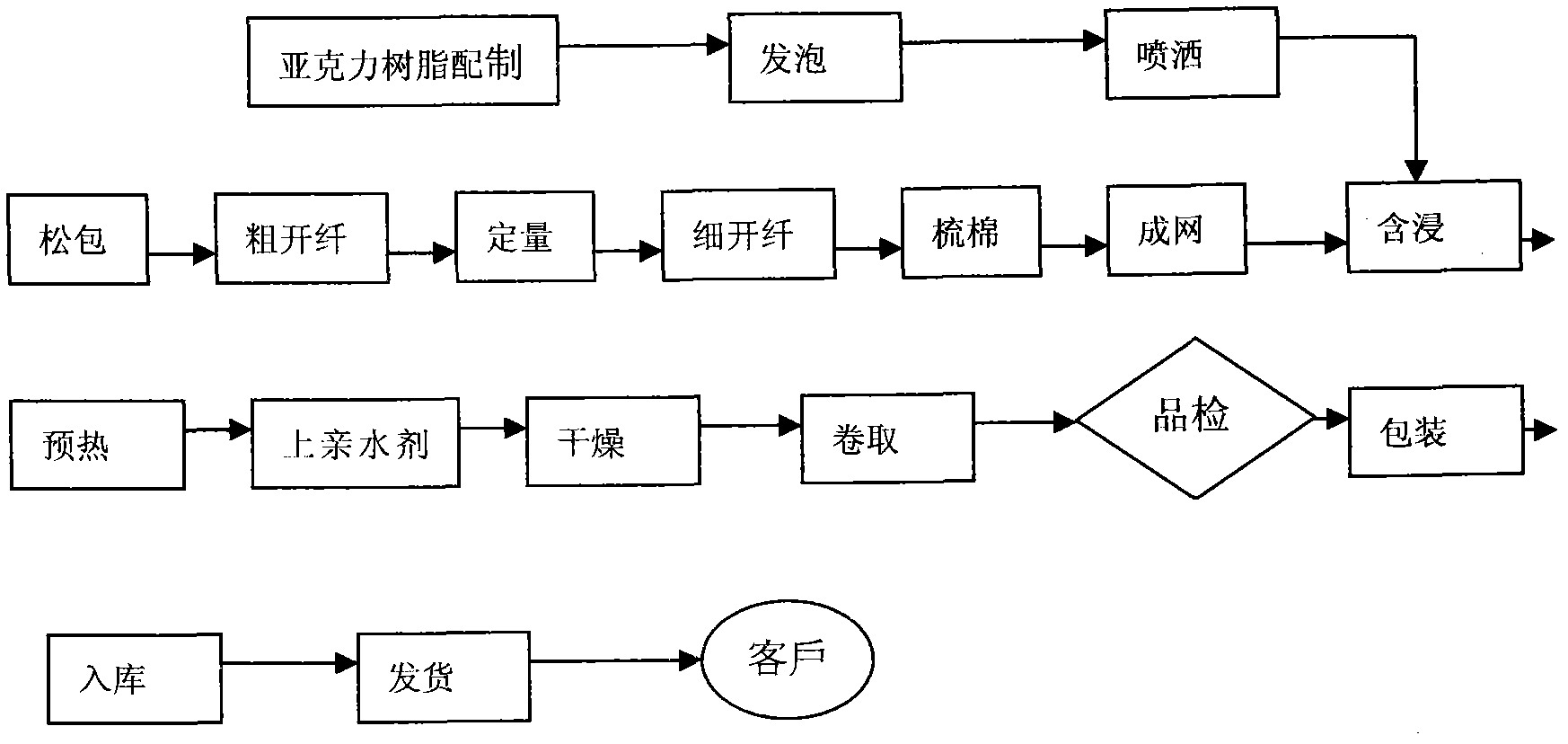

[0018] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The invention adopts cotton-like viscose fiber that can be naturally decomposed as the base material, and low-width Malin environmental protection resin is used as the adhesive for the fiber joint, thereby having the effect of environmental protection.

[0020] Such as figure 1 Shown, the manufacturing process of medical operating tablecloth among the present invention is as follows:

[0021] (1) Loose bales of fibers: Unpack the whole bales of fibers and put them into the feed cotton box in a dispersed manner.

[0022] (2) Coarse opening of the fibers entering the material cotton box: use a set of nail-shaped needle rows to loosen the fibers.

[0023] (3) Determining the weight of the fiber: that is, quantification, setting the required fiber weight on the automatic scale control panel, so as to control the weight of the incoming f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com