Lignin modified PET (Polyethylene Terephthalate) composite material and preparation method thereof

A composite material and lignin technology, applied in the field of lignin-modified PET composite materials and its preparation, to achieve the effects of increasing phenyl content, reducing production costs, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

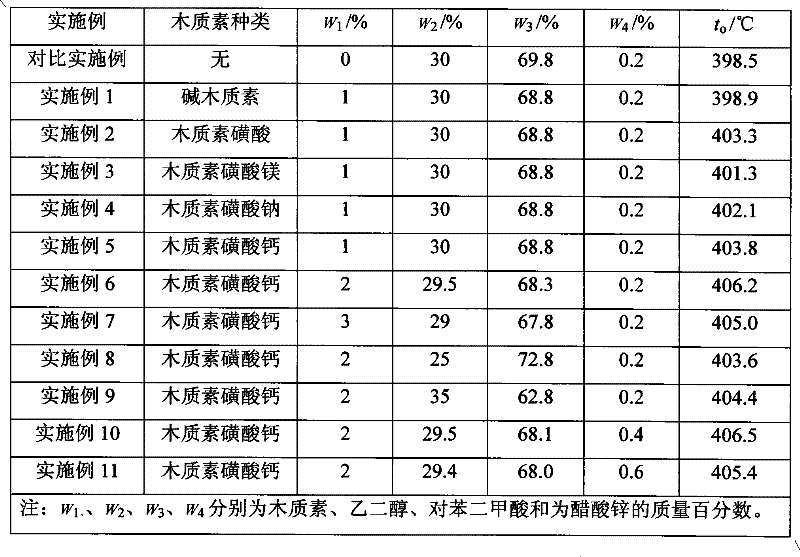

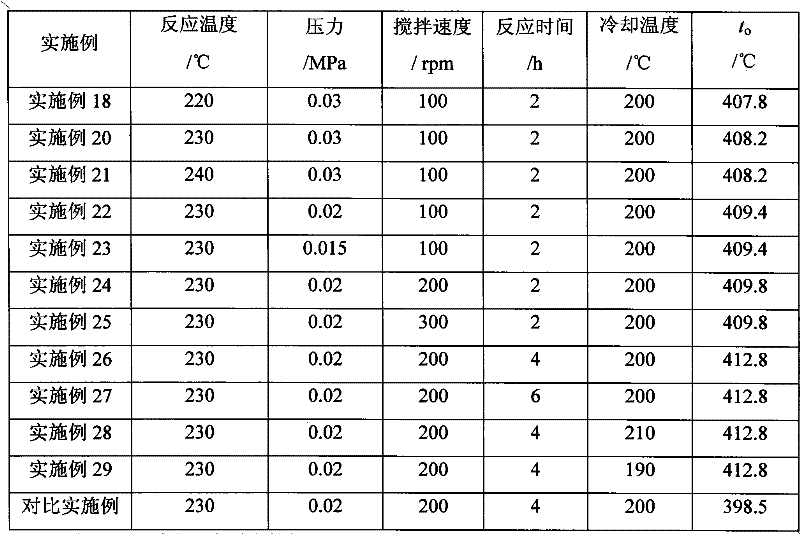

[0021] A preparation method of lignin modified PET composite material, comprising the following steps:

[0022] (1) Esterification reaction: add alkali lignin, ethylene glycol, terephthalic acid and zinc acetate into the reaction kettle according to the mass ratio of 1:30:68.8:0.2, and gradually heat up to 200°C under the protection of nitrogen. The pressure of the reactor was controlled at 0.2MPa, and after reacting for 2 hours at a stirring speed of 100rpm, lignin-modified ethylene terephthalate was obtained;

[0023] (2) Polycondensation reaction. Control the temperature of the lignin-modified ethylene terephthalate prepared in step (1) at 220°C, reduce the pressure in the reactor to 0.03MPa with a vacuum pump, react at a stirring speed of 100rpm for 2 hours, and stop heating , after the temperature in the reactor dropped to 200°C, the material was discharged to obtain a lignin-modified PET composite material, and the heat resistance test results are shown in Table 1.

Embodiment 2

[0025] A preparation method of lignin modified PET composite material, comprising the following steps:

[0026] (1) Esterification reaction: add lignosulfonic acid, ethylene glycol, terephthalic acid and zinc acetate into the reaction kettle according to the mass ratio of 1:30:68.8:0.2, and gradually heat up to 200°C under nitrogen protection , the pressure of the reactor was controlled at 0.2MPa, and after reacting for 2 hours at a stirring speed of 100rpm, lignin-modified ethylene terephthalate was obtained;

[0027] (2) Polycondensation reaction. Control the temperature of the lignin-modified ethylene terephthalate prepared in step (1) at 220°C, reduce the pressure in the reactor to 0.03MPa with a vacuum pump, react at a stirring speed of 100rpm for 2 hours, and stop heating , after the temperature in the reactor dropped to 200°C, the material was discharged to obtain a lignin-modified PET composite material, and the heat resistance test results are shown in Table 1.

Embodiment 3

[0029] A preparation method of lignin modified PET composite material, comprising the following steps:

[0030] (1) Esterification reaction: Add magnesium lignosulfonate, ethylene glycol, terephthalic acid and zinc acetate into the reactor according to the mass ratio of 1:30:68.8:0.2, and gradually heat up to 200 °C under nitrogen protection. °C, the pressure of the reactor was controlled at 0.2MPa, and after 2 hours of reaction at a stirring speed of 100rpm, lignin-modified ethylene terephthalate was obtained;

[0031] (2) Polycondensation reaction. Control the temperature of the lignin-modified ethylene terephthalate prepared in step (1) at 220°C, reduce the pressure in the reactor to 0.03MPa with a vacuum pump, react at a stirring speed of 100rpm for 2 hours, and stop heating , after the temperature in the reactor dropped to 200°C, the material was discharged to obtain a lignin-modified PET composite material, and the heat resistance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com