Device and method for detecting sanding critical flow velocity of gas well

A critical flow rate, gas well technology, used in the measurement of fluid velocity by differential pressure, measurement devices, and the use of cyclone flowmeters to measure fluid velocity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

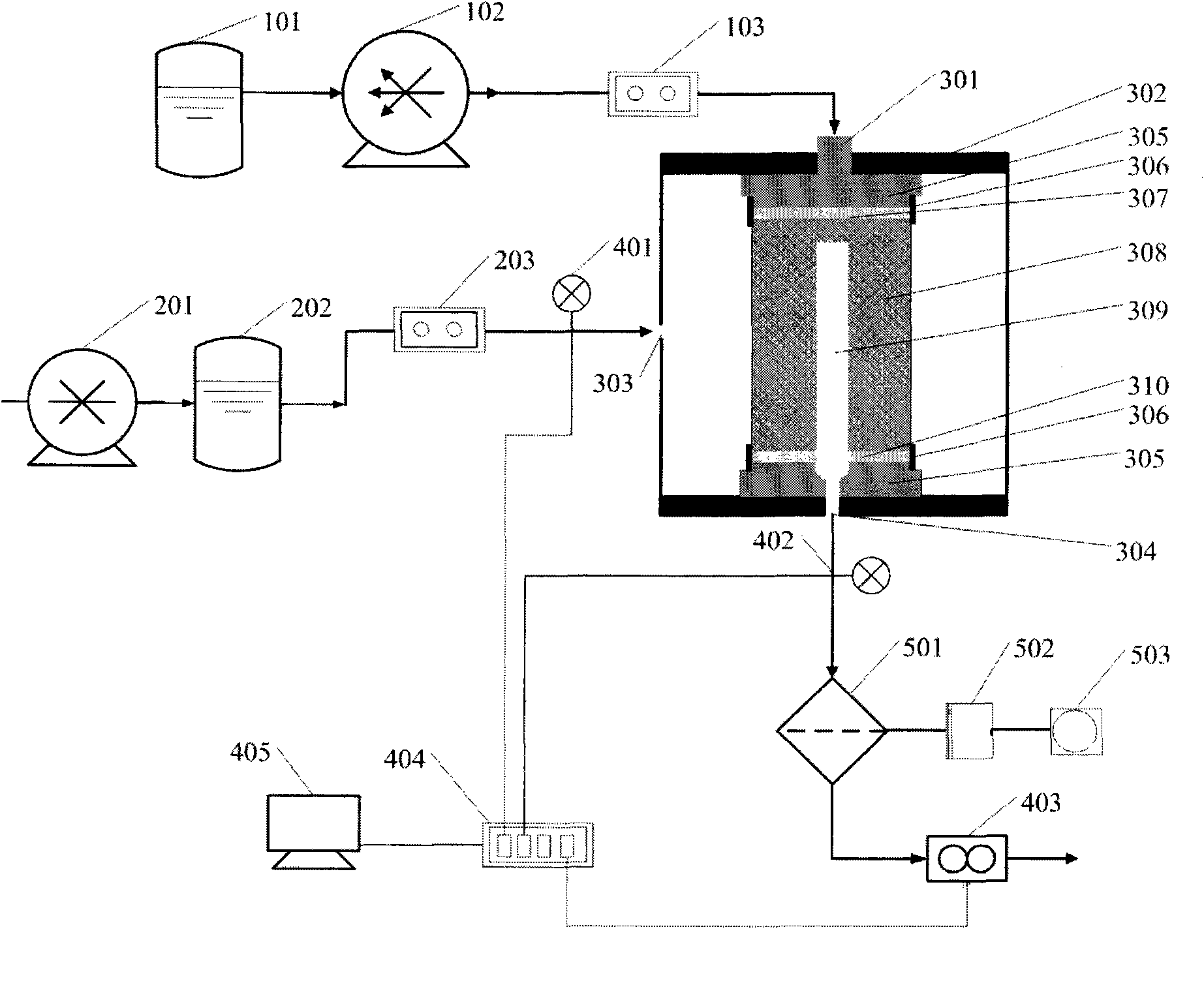

[0023] 1) According to figure 1 As shown in the schematic diagram, connect the axial pressurization system, gas supply system, simulation system, measurement and collection system, sand treatment system, and check the tightness of each component and pipeline;

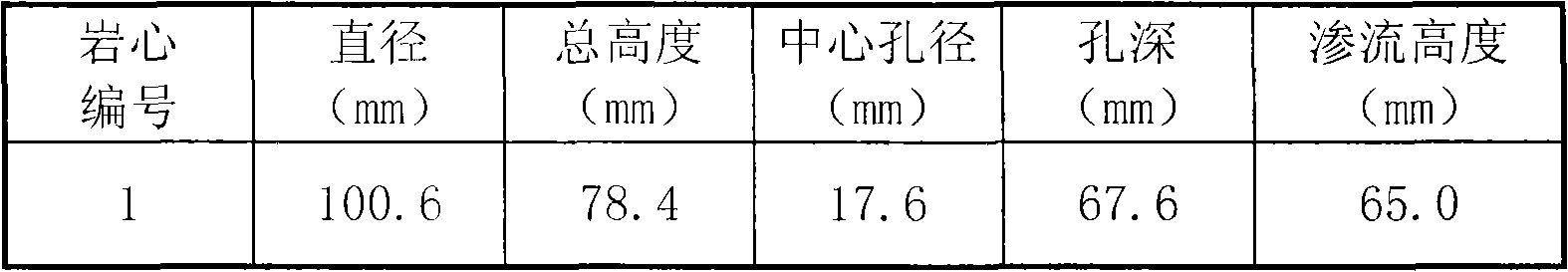

[0024] 2) A rubber gasket 307 is placed on the end face of the full-diameter rock core 308 without holes, and then a self-adhesive sealing tape 306 is used to seal the upper pressure head of the full-diameter rock core 308, the rubber gasket 307 and the core holder 305; the full-diameter rock core 308 is perforated A rubber gasket 310 with holes is placed on the end face, and the aperture of the rubber gasket 310 is equal to or slightly larger than the diameter of the hole 309 in the core, and then the full-diameter core 308, the rubber gasket 310 and the core holder 305 are pressed down using a self-adhesive sealing tape 306 head; the following table 1 shows the full-diameter core size table after drilling and coring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com