Rock burst control method for deep tunnel excavation by adopting TBM (Tunnel Boring Machine)

A rockburst and tunnel technology, applied in the field of rockburst prevention, can solve problems such as prolonging the construction period and reducing the utilization rate of TBM equipment, and achieves the effect of speeding up the construction progress, eliminating the risk of rockburst, and improving the utilization rate of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] Embodiment 2: as Figure 6 As shown, in this case, several parallel tunnels are excavated at the same time, and the construction steps are as follows:

[0027] a2: Same as step a1 in Example 1.

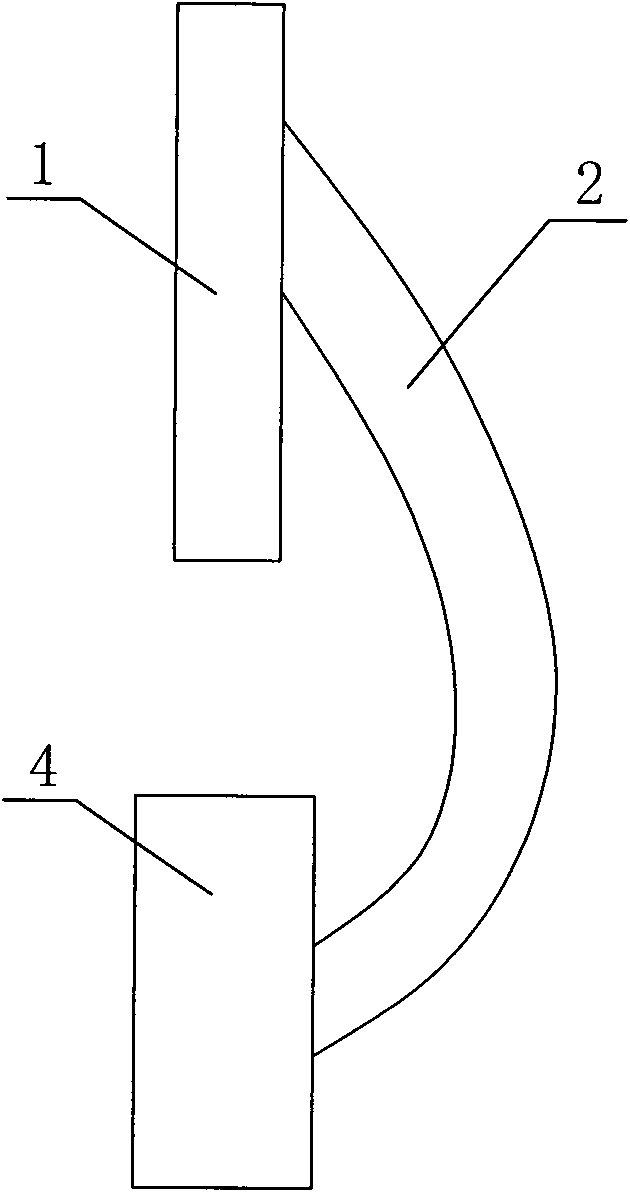

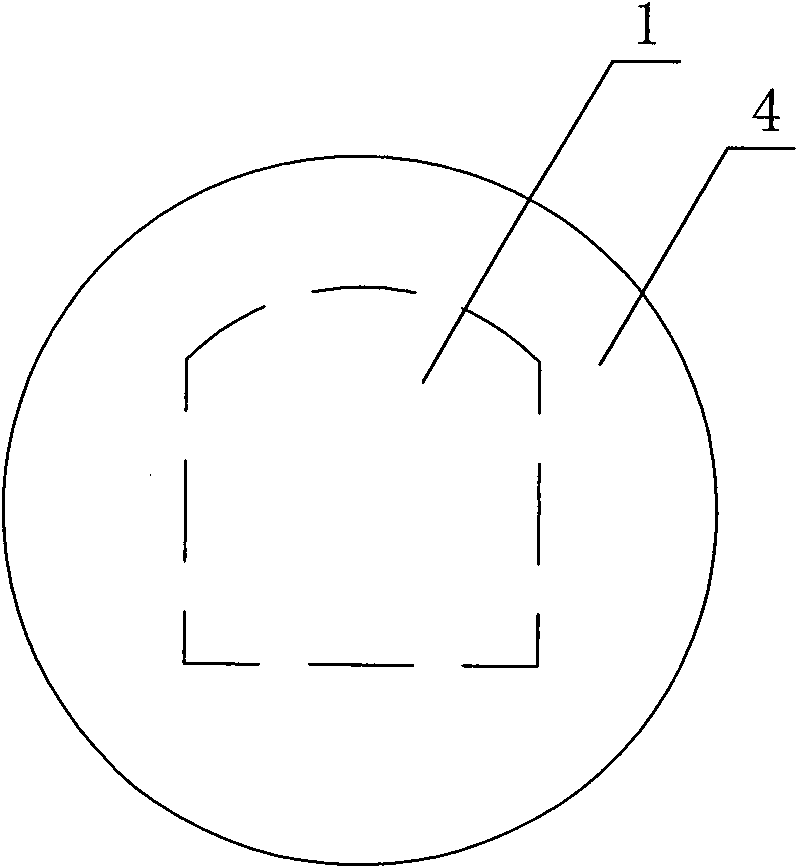

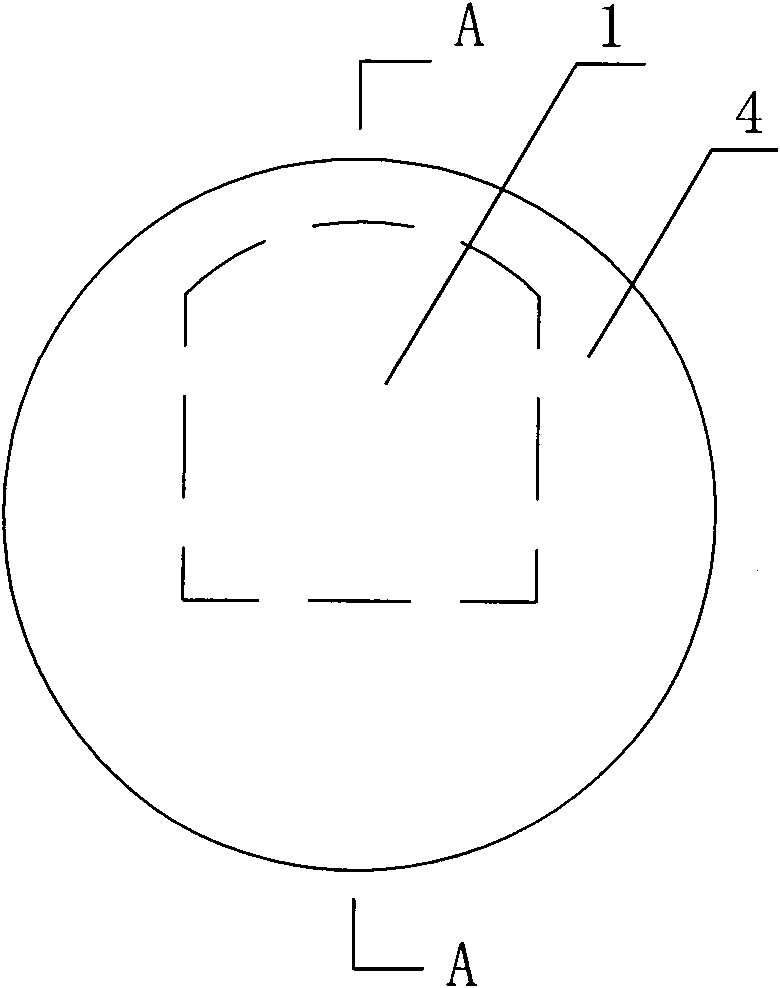

[0028] b2: Excavate a lateral construction branch tunnel 3 from the tunnel parallel to the excavated tunnel section 4 of the TBM to the strong rock blast tunnel section that the TBM needs to pass through, and use it as an auxiliary tunnel for the excavation of the pilot tunnel 1, and then pass through the lateral construction branch tunnel 3 Excavate a pilot tunnel 1 whose size is smaller than the TBM excavation contour line; when excavating the lateral construction branch tunnel 3, it is necessary to excavate from the advanced tunnel to the front of the backward tunnel. The rest are the same as step b1 in Example 1.

[0029] c2: same as step c1 in Example 1.

[0030] Similarly, after the above steps are completed, the risk of rockburst in the secondary excavation of the TBM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com