Conveying device for powder blowers

A transmission device and powder spraying machine technology, which is applied to conveyor control devices, mechanical conveyors, conveyors, etc., can solve the problems of heavy powder spraying machines, potential safety hazards, and low transport efficiency, and achieve high transport efficiency. Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A further detailed description will be made below in conjunction with the accompanying drawings and embodiments of the present invention:

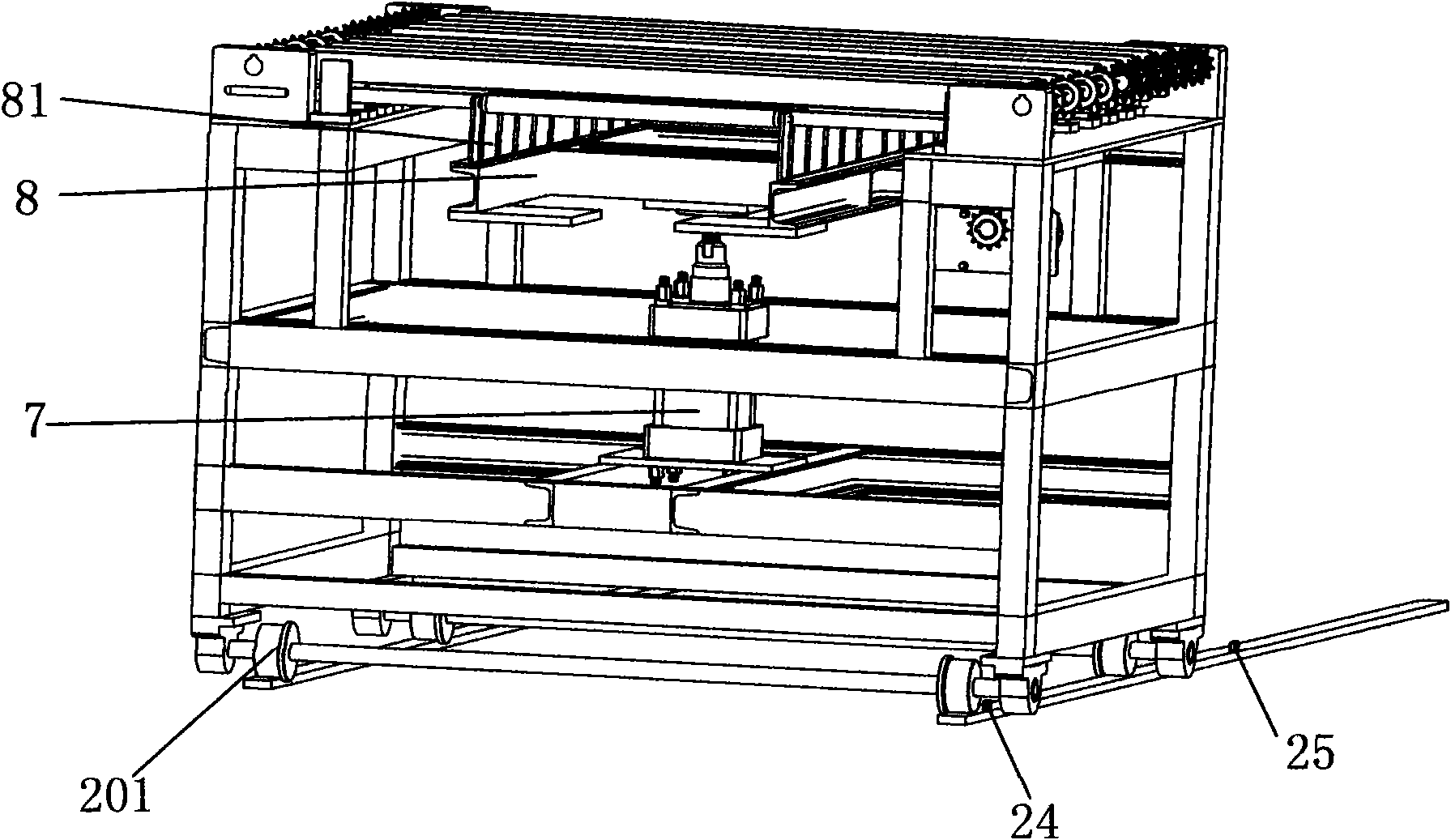

[0019] see Figure 1-4 , the present invention is a conveying device for a powder spraying machine, which includes a fixed frame 1 and a sliding frame 2 close to each other. A conveyor belt 11 is arranged on the fixed frame 1. The conveyor belt 11 can transport the powder spraying machine from left to right. The ground below 2 is provided with conveyor belt 11 and slide rail 21 is vertically set, and the wheel 201 that can slide on slide rail is housed at slide frame 2 bottoms, and slide frame 2 can slide front and rear direction on slide rail by wheel. A longitudinal rotating shaft 3 is respectively arranged on the left and right sides of the top of the slide frame 2, and a plurality of spaced gears 4 are correspondingly provided on the two longitudinal rotating shafts 3, and two longitudinal rotating shafts 3 are sleeved on each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com