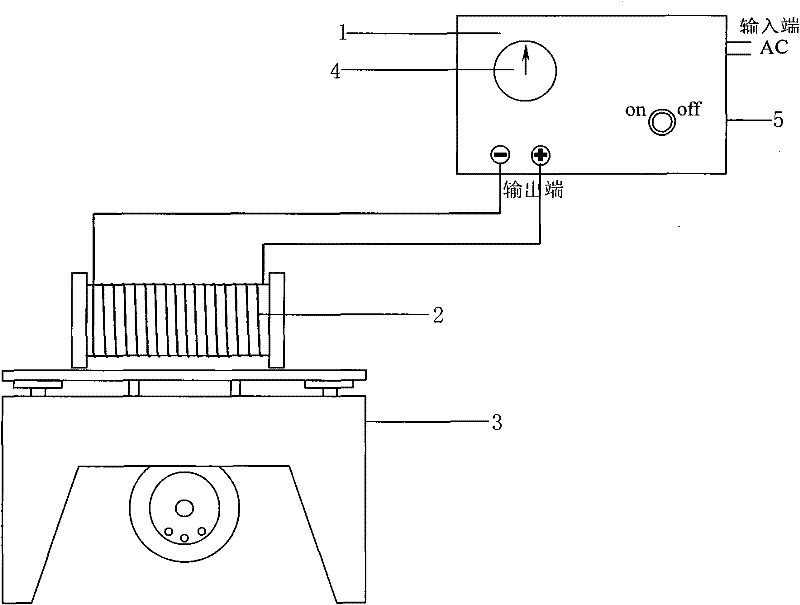

Method for preparing unidirectional distributive steel fiber reinforced mortar and special equipment thereof

A technology of reinforced mortar and special equipment, which is applied in the field of fiber reinforced mortar, can solve the problems of increased cost of raw materials and low efficiency of steel fiber utilization, and achieve the effect of increased cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

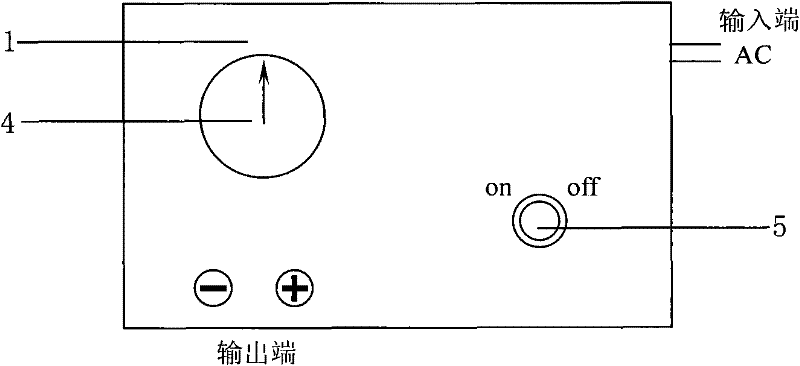

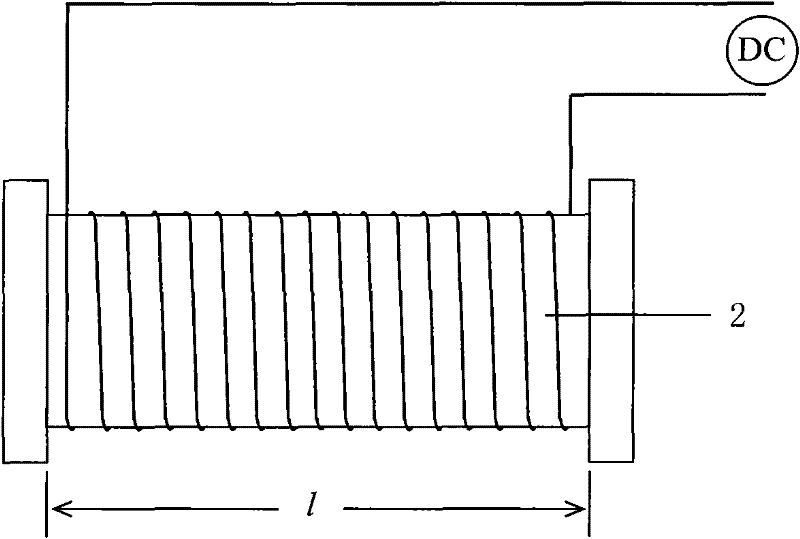

Method used

Image

Examples

Embodiment 1

[0045] The first step is to prepare the steel fiber mortar mixture

[0046] According to the known design method, the mass ratio of the mortar composition components determined by the strength grade of M5 is water: cement: sand: superplasticizer=0.56: 1: 3: 0.003, and the required amount during actual operation is weighed Water: cement and sand, and then take steel fiber with a volumetric dosage of 1.5% in ordinary mortar (the densities of steel, cement, and water are respectively 7800kg / m 3 、3100kg / m 3 、1000kg / m 3 , and the quality of the required steel fiber can be determined accordingly), the steel fiber used is a steel wire cut steel fiber with a length of 13mm and an aspect ratio of 40. First put the weighed cement and sand into the dry material of the mortar mixer and stir evenly, then put in the weighed steel fiber while stirring, then add the weighed mixing water and high-efficiency water reducer, continue stirring for 60 seconds and then discharge , the measured co...

Embodiment 2

[0058] The first step is to prepare the steel fiber mortar mixture

[0059] According to the known design method, the mass ratio of the mortar components whose strength grade is M10 is water: cement: sand: high-efficiency water reducing agent = 0.3: 1: 1.5: 0.006. Water: cement and sand, and then take steel fiber with a volumetric dosage of 1.5% in ordinary mortar (the densities of steel, cement, and water are respectively 7800kg / m 3 、3100kg / m 3 、1000kg / m 3 , and the quality of the required steel fiber can be determined accordingly), the steel fiber used is a steel wire cut steel fiber with a length of 13mm and an aspect ratio of 40. Put the weighed water into the mixer first, then put in the weighed cement, turn on the mixer and stir for 20 seconds, add the weighed sand while stirring, then add the weighed steel fiber while stirring, and continue stirring for 180 seconds , the measured consistency of the steel fiber mortar mixture is 40mm;

[0060] The second step, pourin...

Embodiment 3

[0071] According to the known design method, the mass ratio of the mortar components whose strength grade is M7.5 is water: cement: sand: high-efficiency water reducer = 0.42: 1: 2: 0.004. Amount of water: cement and sand, then take the steel fiber that is mixed with a volume of 0.5% in ordinary mortar (the densities of steel, cement, and water are respectively 7800kg / m 3 、3100kg / m 3 、1000kg / m 3 , and the quality of the required steel fiber can be determined accordingly), the steel fiber used is a steel wire cut steel fiber with a length of 13mm and an aspect ratio of 40. Put the weighed water and superplasticizer into the mixer first, then put in the weighed cement, turn on the mixer and stir for 120 seconds, add the weighed sand while stirring, and then put in the weighed steel fiber while stirring , continue to stir for 300 seconds, and measure the consistency of the steel fiber mortar mixture to be 80mm;

[0072] The second step, pouring into the test mold

[0073] Pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com