Method and special equipment for preparing unidirectionally-distributed steel fiber reinforced cement paste

A special equipment and steel fiber technology, which is applied in the field of preparing unidirectionally distributed steel fiber reinforced cement slurry, can solve the problems of increased raw material cost and low effective utilization efficiency of steel fiber, and achieve the increase of raw material cost and outstanding substantive effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The first step is to prepare the steel fiber cement slurry mixture

[0047] According to the mass ratio of water: cement: superplasticizer = 0.60: 1: 0 to form cement slurry, add steel fiber with a volume content of 0.3% in the cement slurry, first put the weighed mixing water into the mixer, Then put in the weighed cement and stir for 20 seconds, then slowly put in the weighed steel fiber while keeping the mixer continuously stirring, keep the mixer continuously stirring during the steel fiber feeding process, and continue stirring for 60 seconds after the steel fiber feeding is completed. Material, the measured fluidity of the steel fiber cement slurry mixture is 180mm;

[0048] The second step, pouring into the test mold

[0049] Pour the steel fiber cement slurry mixture prepared in the first step into a non-metallic test mold of 40mm×40mm×160mm;

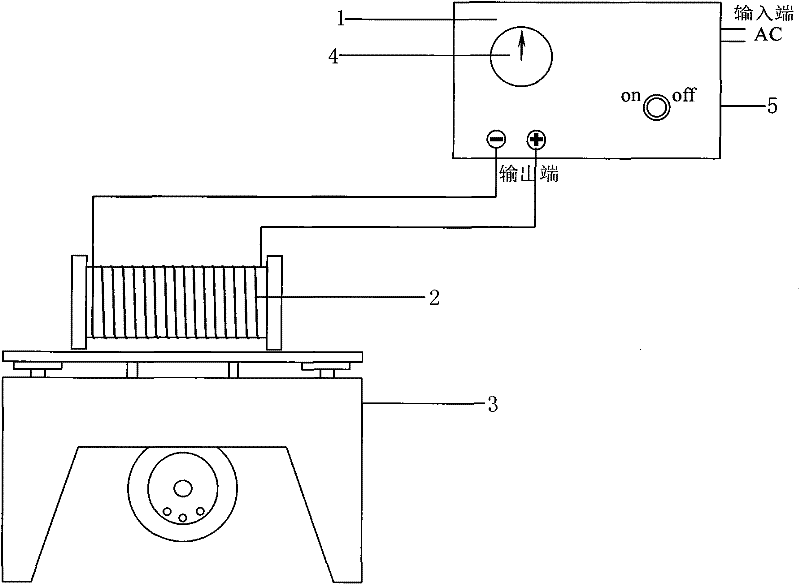

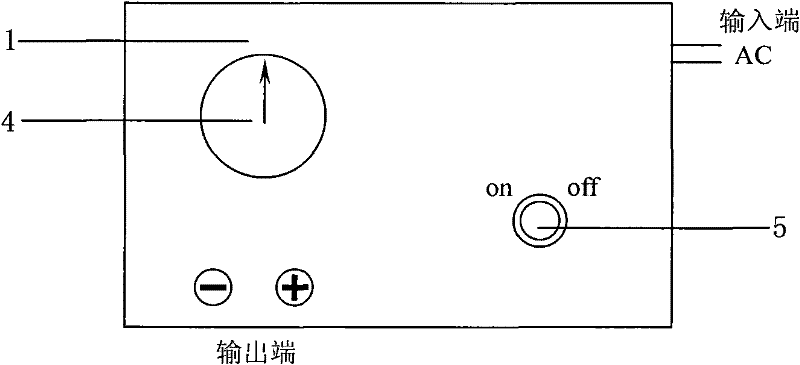

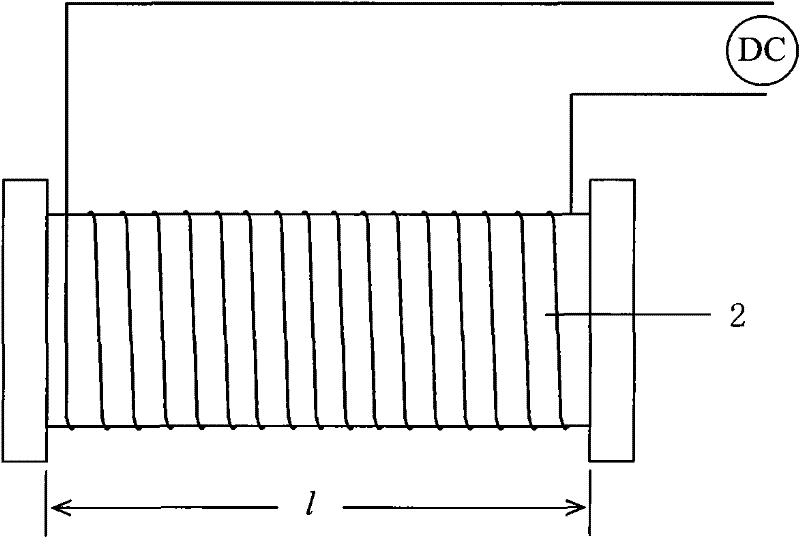

[0050] The third step is to apply a magnetic field

[0051] Place the non-metallic test mold obtained in the second ...

Embodiment 2

[0059] The first step is to prepare the steel fiber cement slurry mixture

[0060] According to the mass ratio of water: cement: high-efficiency water reducer = 0.20:1:0.0075 to form cement slurry, add steel fiber with a volume content of 1.0% in the cement slurry, first mix the weighed mixing water and high-efficiency water reducer Put the water agent into the mixer, then put in the weighed cement and stir for 120 seconds, then slowly put in the weighed steel fiber while keeping the mixer continuously stirring, keep the mixer continuously stirring during the steel fiber feeding process, and continue to stir after the steel fiber feeding is completed After stirring for 300 seconds, the material is discharged, and the fluidity of the steel fiber cement slurry mixture is determined to be 90mm;

[0061] The second step, pouring into the test mold

[0062] Pour the steel fiber cement slurry mixture prepared in the first step into a non-metallic test mold of 40mm×40mm×160mm;

[0...

Embodiment 3

[0072] The first step is to prepare the steel fiber cement slurry mixture

[0073] According to the mass ratio of water: cement: high-efficiency water reducer = 0.35:1:0.004 to form cement slurry, in this cement slurry, add steel fiber with a volume content of 0.4%, first mix the weighed water and high-efficiency water reducer Put the water agent into the mixer, then put in the weighed cement and stir for 120 seconds, then slowly put in the weighed steel fiber while keeping the mixer continuously stirring, keep the mixer continuously stirring during the steel fiber feeding process, and continue to stir after the steel fiber feeding is completed After stirring for 300 seconds, the material is discharged, and the fluidity of the steel fiber cement slurry mixture is determined to be 135mm;

[0074] The second step, pouring into the test mold

[0075] Pour the steel fiber cement slurry mixture prepared in the first step into a non-metallic test mold of 40mm×40mm×160mm;

[0076] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com