Carbon fiber board prestress tension clamp

A carbon fiber plate and prestressing technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve problems such as the inability to reinforce carbon fiber plate engineering structures, achieve the effects of increasing force, preventing fracture, and improving clamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

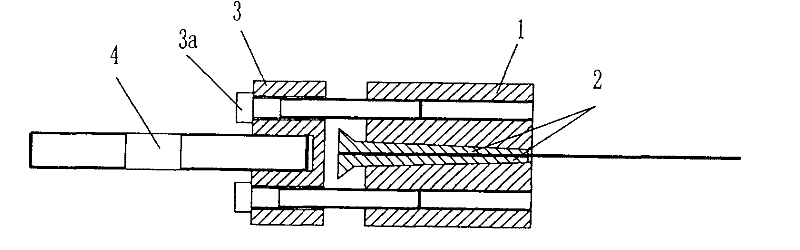

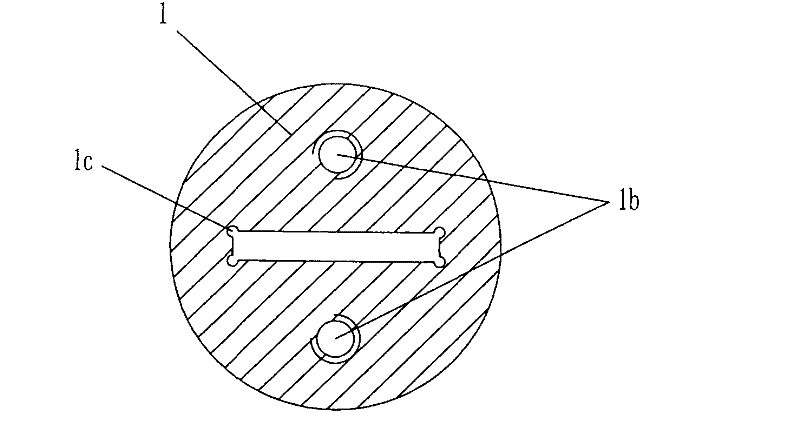

[0036] figure 1 It is a structural schematic diagram of a prestressed tensioning fixture for a carbon fiber plate of the present invention; figure 2 is a sectional view of the clamping sleeve; image 3 for figure 2 The enlarged view of the section along A-A; Figure 4 It is a schematic diagram of the wedge-shaped clip wedged into the clamping sleeve; Figure 5 for Figure 4 Enlarged view of part P in the middle; Figure 6 It is a schematic diagram of the structure of the pre-jacking device; Figure 7 is the B-direction view of the support plate II; Figure 8 It is a schematic diagram of the pre-jacking operation; Figure 9 It is a schematic diagram of the tensioning state of the tensioning fixture; Figure 10 It is a schematic diagram of the structure of the jacking device; Figure 11 It is a schematic diagram of the jacking operation; Figure 12 It is a schematic diagram of the structure of the support plate II with dovetail operation; Figure 13 for Figure 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com