Instantaneous heating core

A heating core, instant heating technology, applied in the direction of steam generation, steam generation method, lighting and heating equipment, etc., can solve the problems of poor cleaning, disinfection, decontamination effect, lack of pressure, etc., to ensure the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings of the specification.

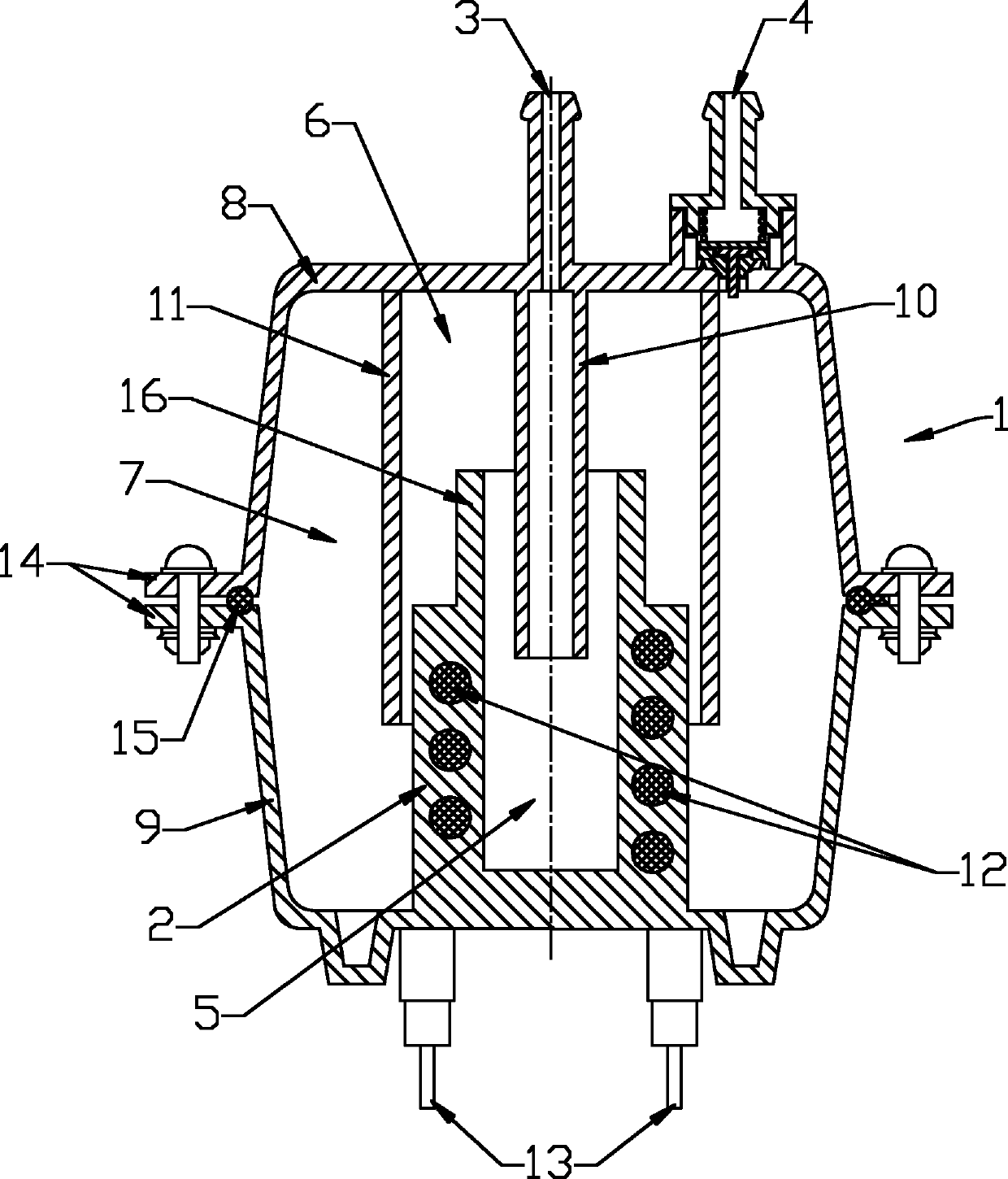

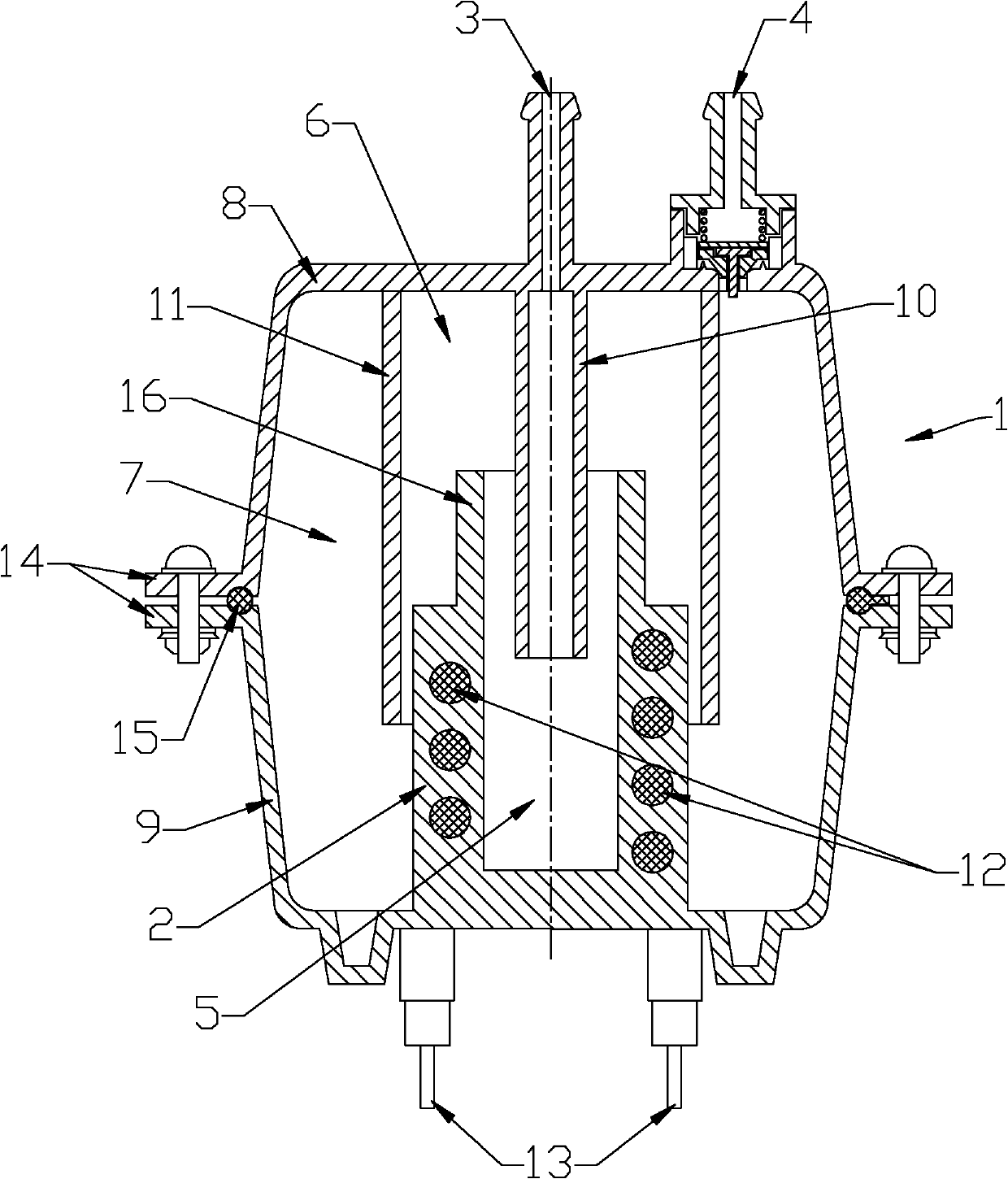

[0019] The instant heating core of the present invention, such as figure 1 As shown, the heating element 2 is arranged in the inner space of the housing 1, and the water inlet 3 and the steam outlet 4 are arranged on the housing 1. The inner space of the housing 1 is sequentially from the water inlet 3 to the steam outlet 4 A first vaporization cavity 5, a second vaporization cavity 6, and a third vaporization cavity 7 are provided, and the volumes of the first vaporization cavity 5, the second vaporization cavity 6, and the third vaporization cavity 7 are sequentially increased. Preferably, the cross-sectional areas of the first vaporization cavity 5, the second vaporization cavity 6, and the third vaporization cavity 7 increase by a ratio of 1-3 times. In the present invention, by setting three vaporization chambers with increasing volumes from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com