Expansion screw

An expansion screw and screw technology, applied in the direction of screws, pins, nuts, etc., can solve the problems of cumbersome working steps, deformation of the screw 11, inability to screw the nut 14, etc., and achieve simplified operation steps, reliable use, and avoid thread damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

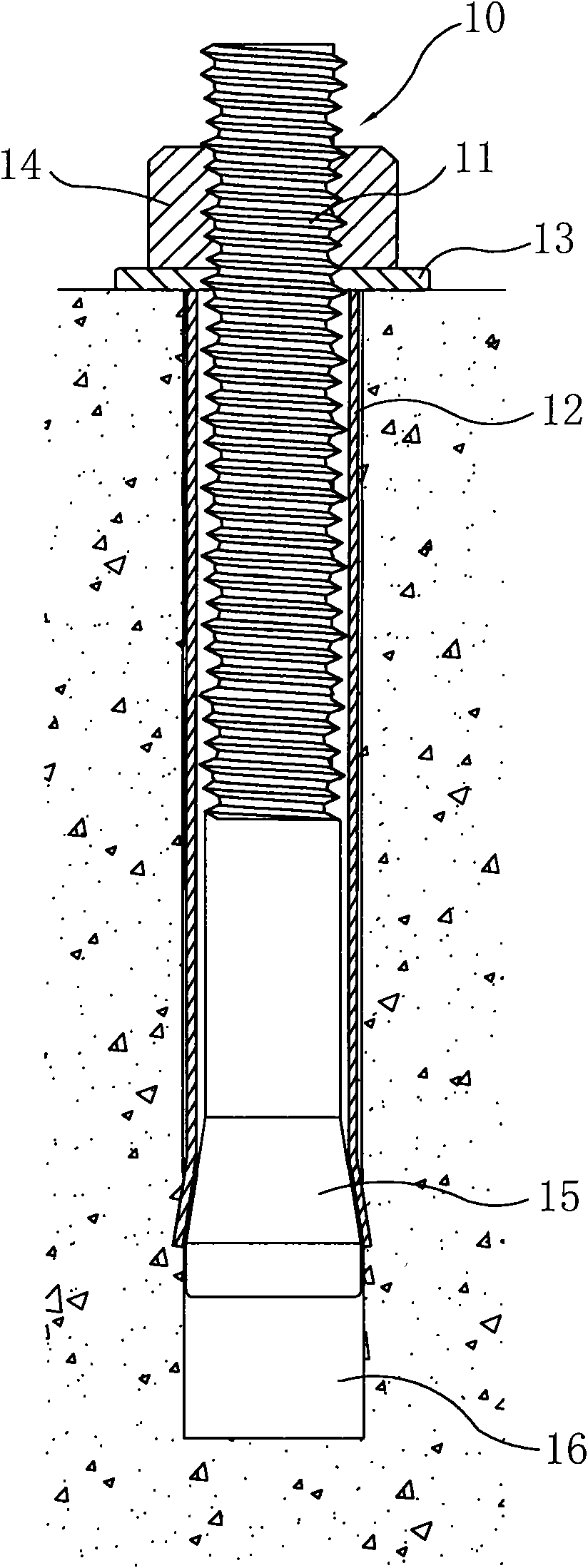

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In view of the foregoing shortcomings of the prior art, the applicant invented an expansion screw that can simplify the application steps. The invention does not need to be driven into the hole in use, but can avoid the situation that the insertion depth is insufficient and the screw is broken, and the operation is easier and more accurate. Examples are now listed in conjunction with the drawings to detail the structural features and use effects of the present invention.

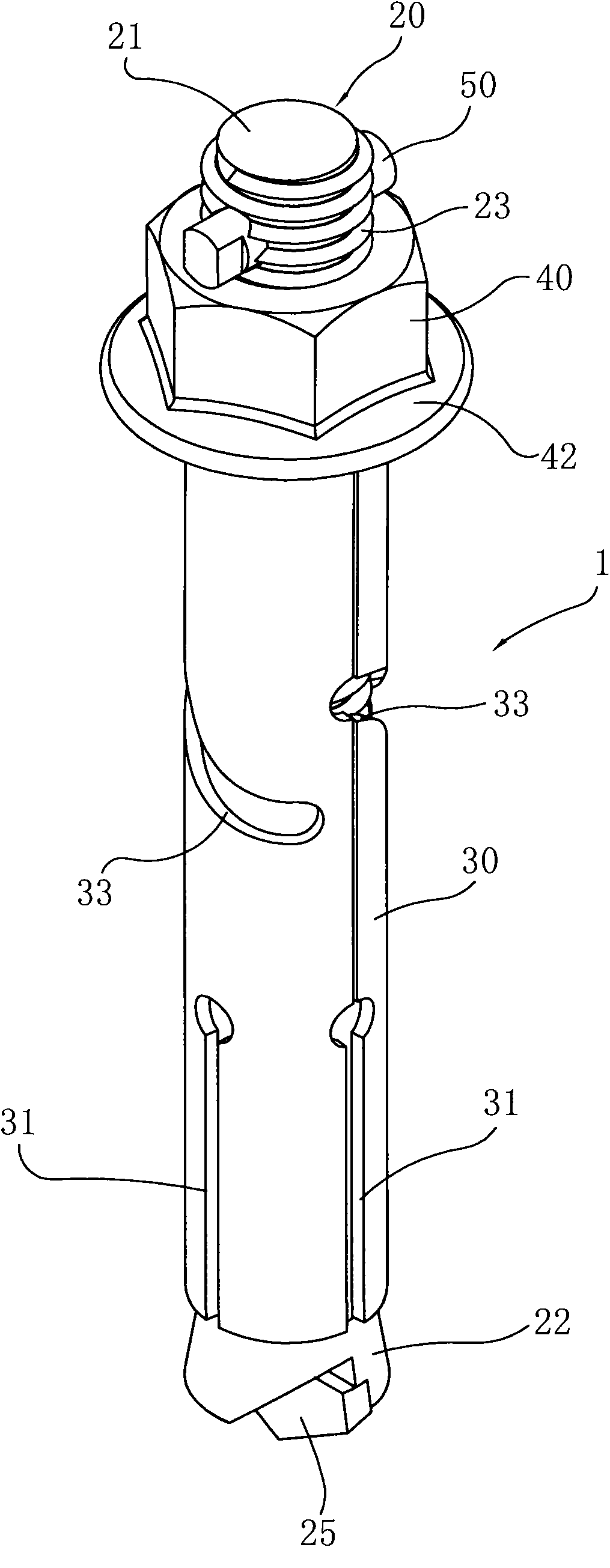

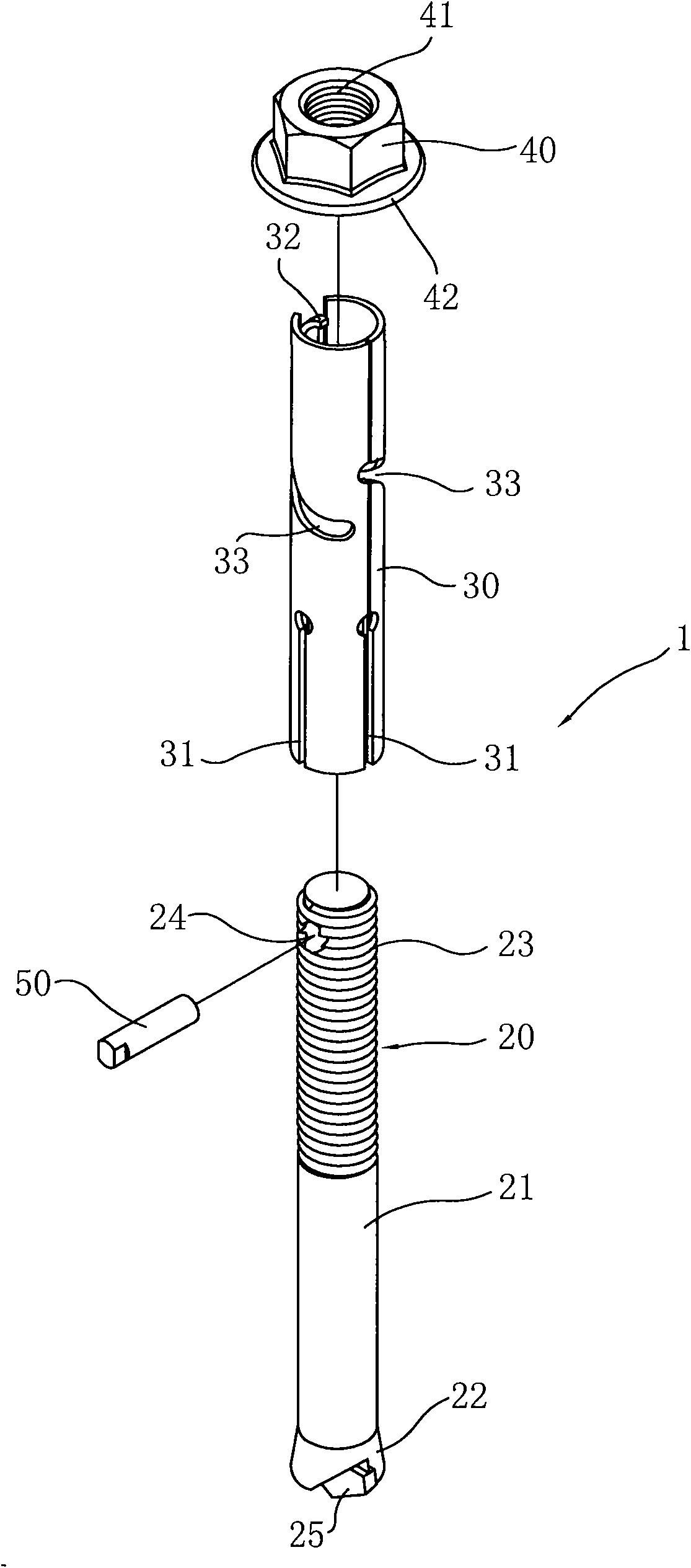

[0021] See figure 2 , image 3 . The expansion screw disclosed in the present invention is an expansion screw 1 with high load-bearing capacity, which is mainly used for concrete floors or walls. The expansion screw 1 includes a screw device 20, a positioning sleeve 30, a nut device 40, and an anti-return pin 50. The positioning sleeve 30 is sleeved on the outside of the screw device 20. The nut device 40 is screwed on the screw device 20. The anti-return pin 50 is provided on the screw device 20 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com