Large-size variable-frequency energy-saving fan

A fan and large-scale technology, applied in the field of large-scale frequency conversion control energy-saving fans, can solve the problems of unsatisfactory service life, high exhaust fan speed, high maintenance expenditure, etc., and achieve the effects of saving electricity expenses, high safety, and strong anti-oxidation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

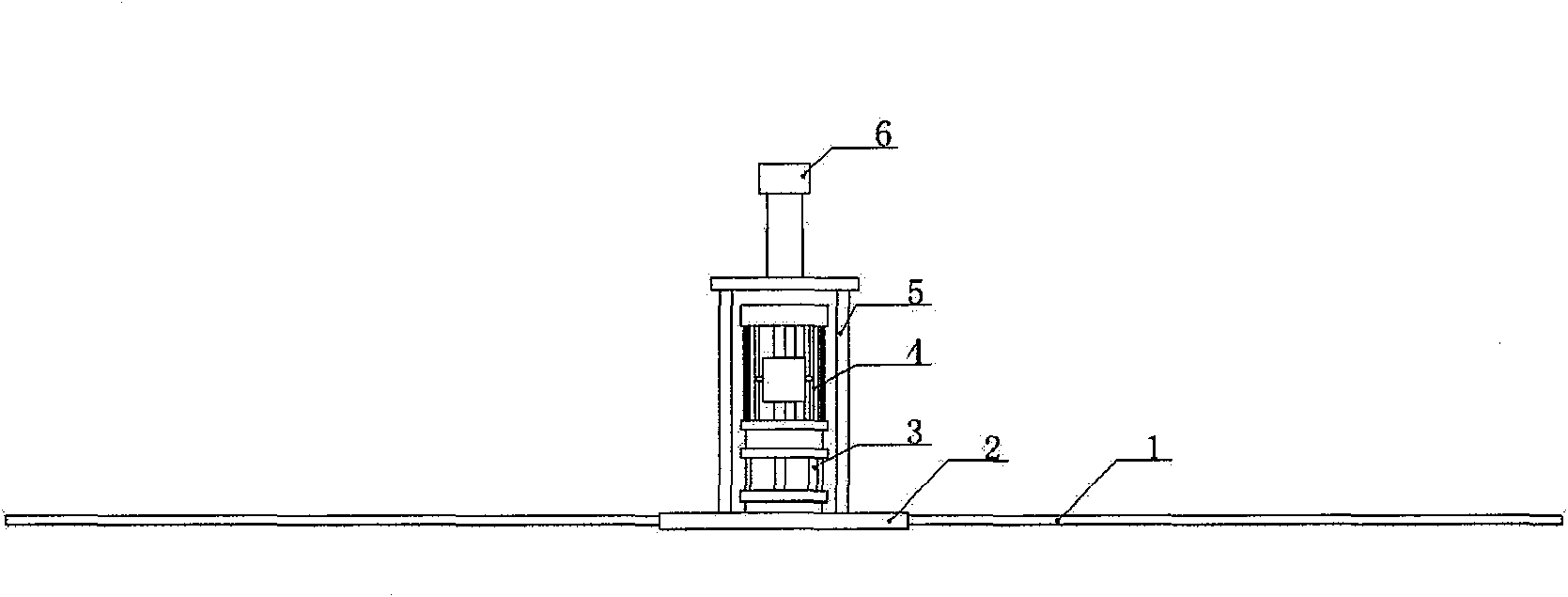

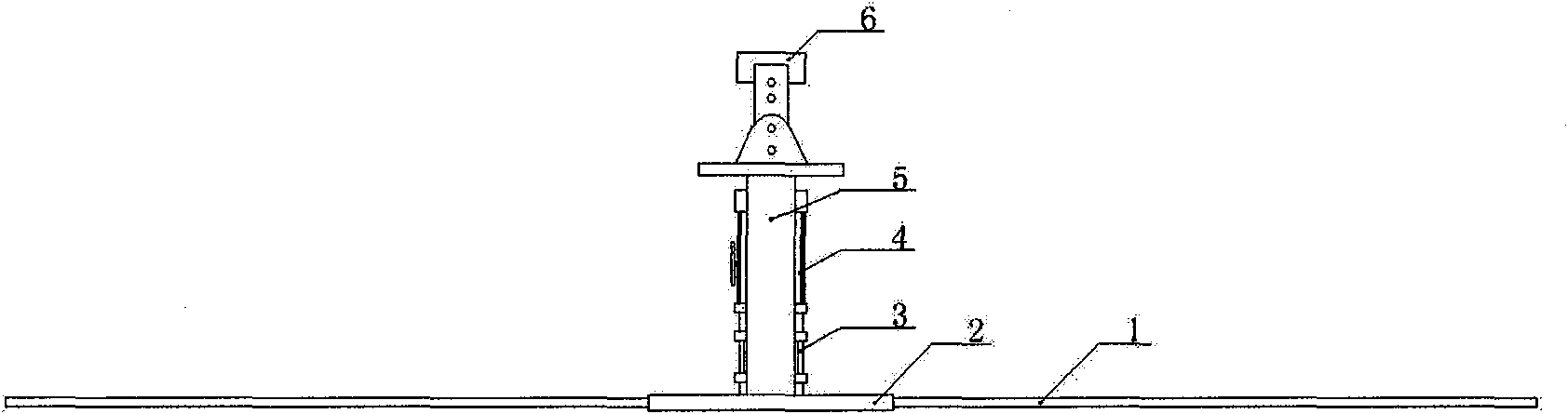

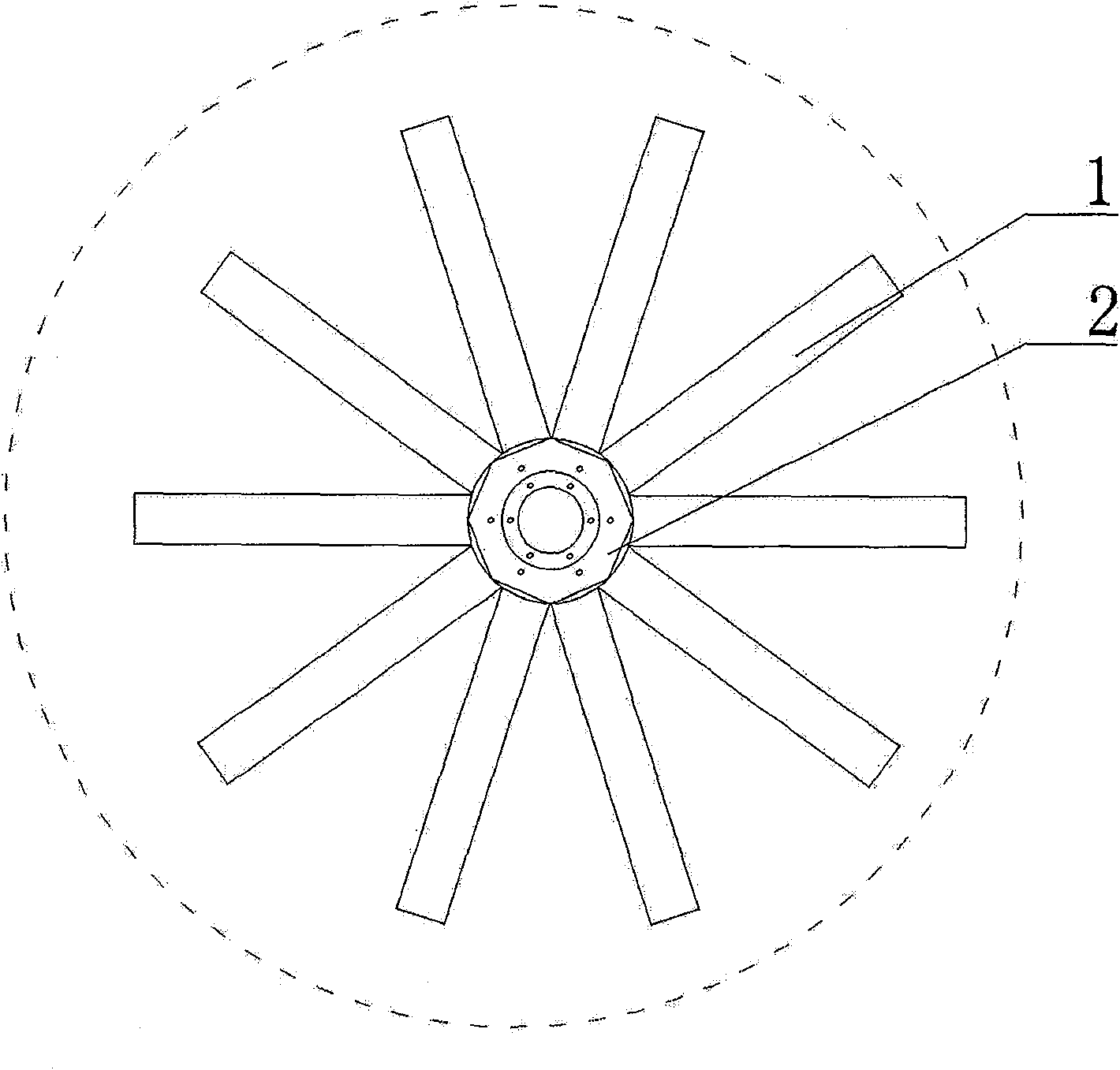

[0014] The main feature of the present invention is a super-large industrial ventilation and exhaust equipment, whose main function is completely different from the common ventilation and exhaust equipment in the market today. The maximum length of the fan blades of the present invention can reach about 3.5 meters. When it is placed under the beam of a large workplace, its effective ventilation area can reach tens of meters below, so using one fan can effectively solve the problem of ventilation and cooling in a workplace of 450-600 square meters. The upper end of the present invention adopts a steel fixing member 6 to be fixed with the crossbeam of the building or the I-shaped structural beam of the steel structure factory building, and the fan motor 4 is vertically fixed in the open motor fixing seat 5 downwards, and the upper end of the fixing seat is connected with the hanging frame. The rigid fixed components for hanging are closely connected together, the lower end is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com