Landing beam sliding hydraulic support system for coal mine

A technology of hydraulic support and roof beam, which is used in mine roof support, mining equipment, earthwork drilling and other directions, can solve the problems that uneven roof cannot be effectively supported, and hydraulic support cannot be solved at the same time, so as to improve labor productivity and reduce support. process, the effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

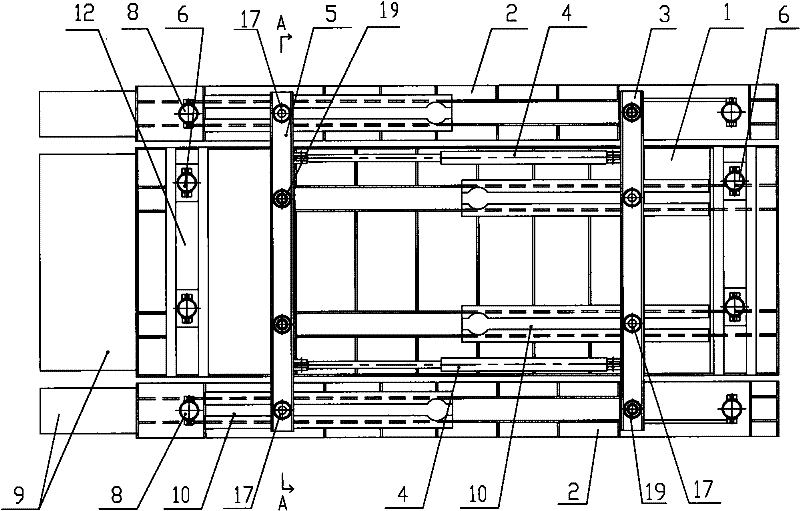

[0060] combine figure 1 As shown, the roof girder sliding hydraulic support system for coal mines includes a main support beam 1, a main beam support device 6 located below the main support beam 1, and side rails placed on both sides of the main support beam 1. The distribution beam 2 and the side beam supporting device 8 placed under the side distribution beam 2 . Below the main supporting beam 1 and the side supporting beam 2, there are side beam connecting beams 3 and main beam connecting beams 5 arranged in parallel. The middle part of the side beam connecting beams 3 is connected to the bottom of the main supporting beam 1 through a sliding connection mechanism 17, and can slide and It does not fall off from the main supporting beam 1; the two ends of the side beam connecting beam 3 are connected to the bottom of the side supporting beam 2 through the movable connection mechanism 19. The middle part of the main beam connecting beam 5 is connected to the bottom of the mai...

Embodiment 2

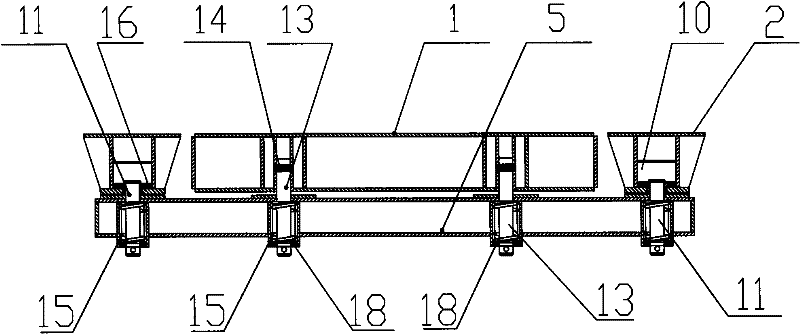

[0077] This embodiment proposes another design scheme of the sliding connection mechanism 17, combining Figure 5 As shown, a boss 20 is arranged on the lower surface of the main support beam 1 (not shown in the figure) and the side distribution beam 2, and the boss 20 is arranged along the length direction of the main support beam 1 and the side distribution beam 2. A pair of rollers 21 are arranged in the track of platform 20, and this roller 21 is connected with main girder coupling beam 5 and side beam coupling beam 3 (not shown in the figure), and can drive main girder coupling beam 5 and side beam coupling beam 3 in convex Slide in the track of platform 20.

[0078] An elastic device 15 is arranged between the main beam connecting beam 5, the side beam connecting beam 3 and the boss 20, and the elastic device 15 can keep the main beam connecting beam 5 and the side beam connecting beam 3 close to the main supporting beam 1 and the Side beam 2. At the same time, it can ...

Embodiment 3

[0080] combine image 3 As shown, the difference between this embodiment and Embodiment 1 is that a fixed side connecting beam 7 is added, and the two ends of the fixed side connecting beam 7 are respectively fixedly connected under one end of the side matching beam 2 . By adding the fixed side connecting beam 7, the combination of the two side matching beams 2 is made more stable, and the integrity and supporting strength of the hydraulic support can be enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com