Manufacturing device for silicon carbide single crystal

A technology of silicon carbide single crystal and manufacturing device, which is applied in the direction of single crystal growth, single crystal growth, post-processing device, etc., can solve the problem of sufficient particle removal and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0038] figure 1 It is a sectional view of the SiC single crystal manufacturing apparatus of this embodiment. Hereinafter, the structure of the SiC single crystal manufacturing apparatus will be described with reference to this figure.

[0039] figure 1 The shown SiC single crystal manufacturing apparatus 1 supplies SiC source gas 3 containing Si and C through an inflow port 2 provided at the bottom, and discharges it through an upper outflow port 4 . A SiC single crystal 6 is crystal-grown on a seed crystal 5 made of a SiC single crystal substrate.

[0040] The SiC single crystal manufacturing apparatus 1 is equipped with a vacuum container 7, a first heat insulating material 8, a heating container 9, a reaction container 10, a pipe material 11, a second heat insulating material 12, a first heating device 13, and a second heating device. 14.

[0041] The vacuum container 7 has a hollow cylindrical shape, and has a structure capable of introducing argon gas and the like, ho...

no. 2 Embodiment approach

[0066] Next, a second embodiment will be described. This embodiment is further provided with a baffle plate compared to the first embodiment, and other points are the same as the first embodiment, so only the different parts will be described.

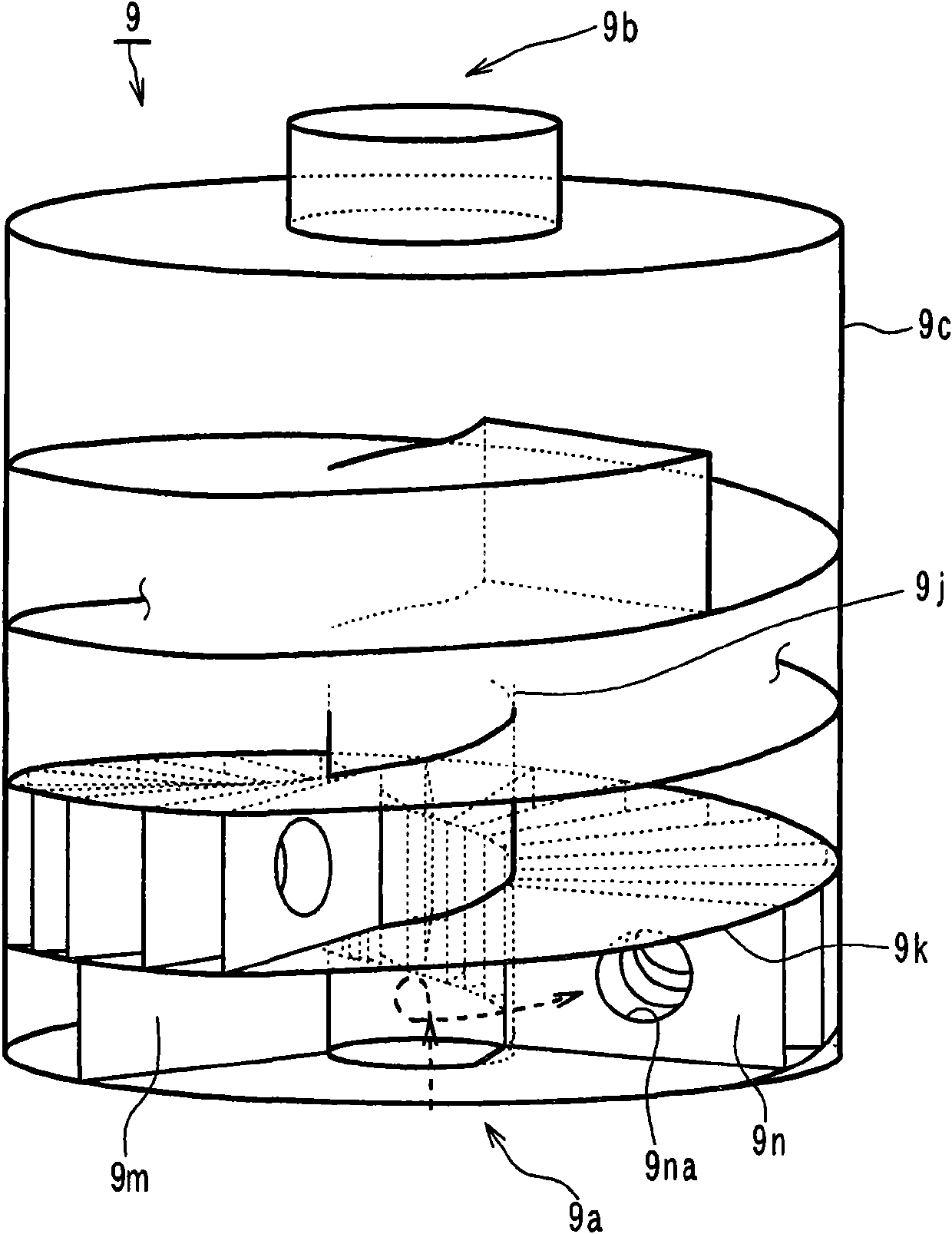

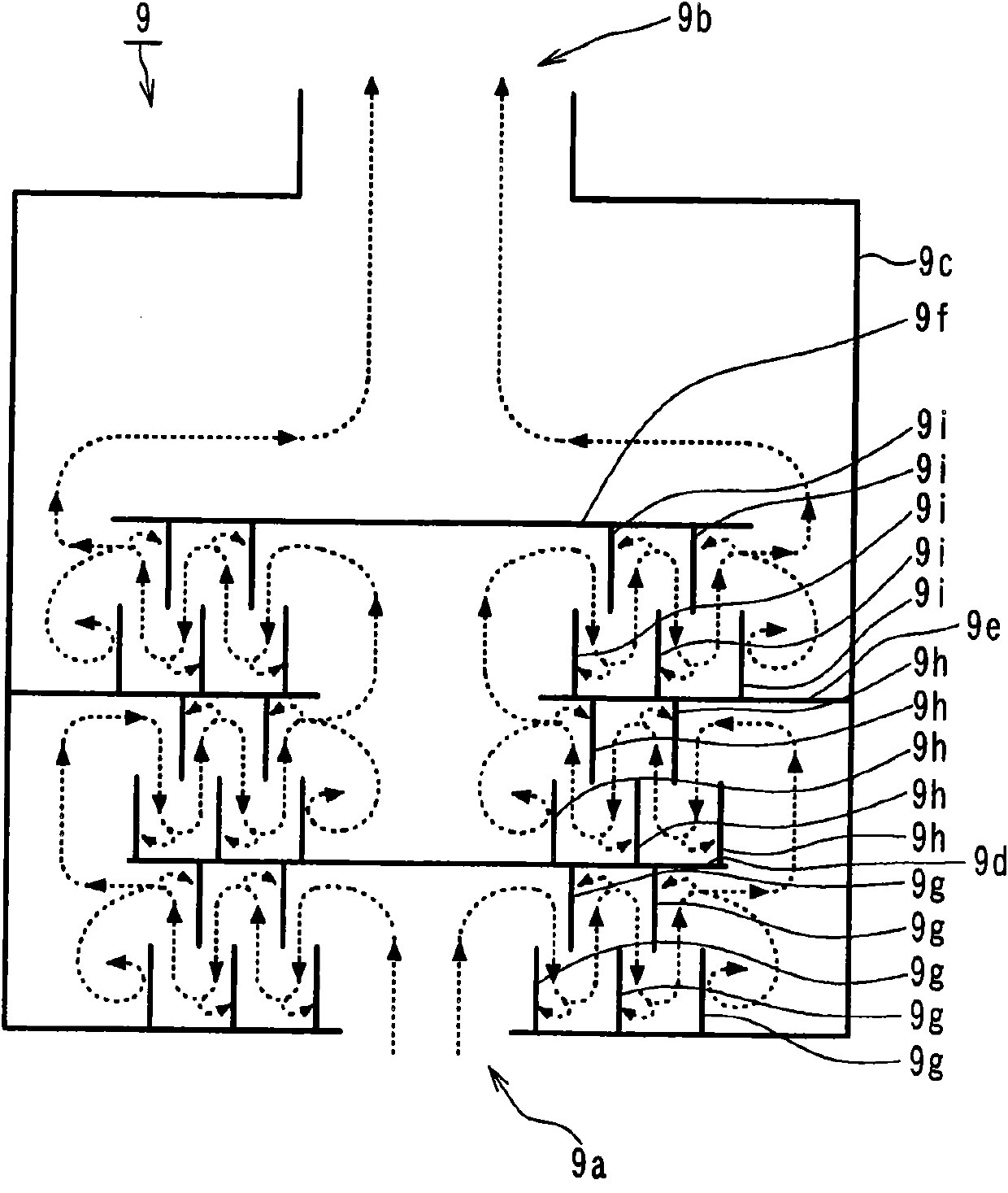

[0067]FIG. 3 is a schematic view of the heating container 9 included in the SiC single crystal manufacturing apparatus of this embodiment, FIG. 3( a ) is a schematic cross-sectional view, and FIG. 3( b ) is a schematic perspective view. Furthermore, other parts of the SiC single crystal manufacturing apparatus are the same as figure 1 The device of the first embodiment shown is the same.

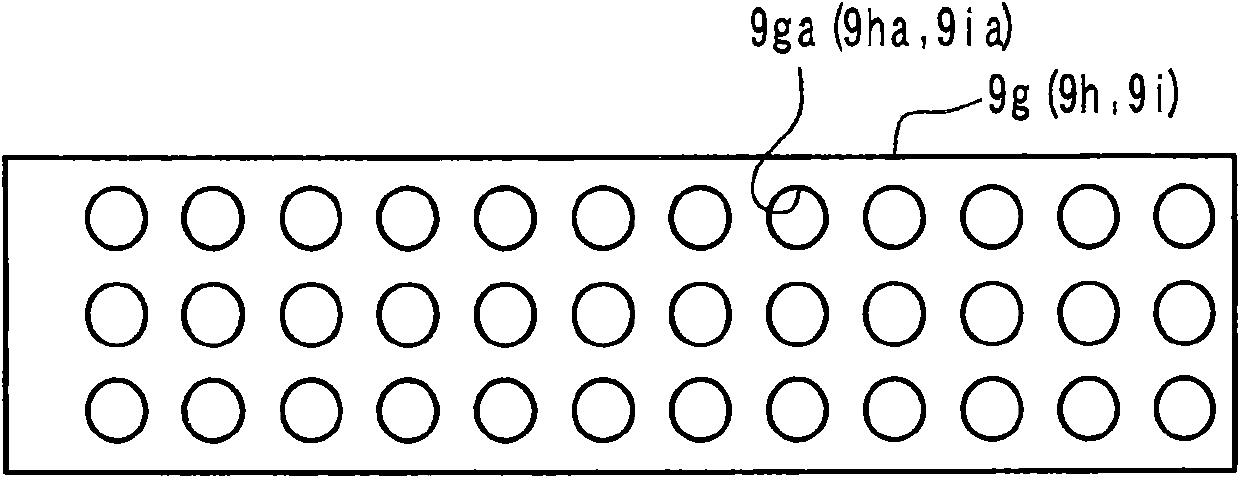

[0068] As shown in Fig. 3 (a), (b), the heating vessel 9 is provided with baffles 9d to 9f aligned with the baffles 9d to 9f in a direction perpendicular to the central axis of the hollow cylindrical member 9c. Shutters (sub-baffles) 9g, 9h, and 9i extend in a direction that intersects and also crosses the radial direction of the central axis of th...

no. 3 Embodiment approach

[0073] Next, a third embodiment of the present invention will be described. In this embodiment, a plurality of baffles 9g to 9i described in the second embodiment are defined, and other points are the same as the second embodiment, so only different parts will be described.

[0074] Figure 4 It is a schematic cross-sectional view of the heating vessel 9 included in the SiC single crystal manufacturing apparatus of the present embodiment. Furthermore, other parts of the SiC single crystal manufacturing apparatus are the same as figure 1 The device of the first embodiment shown is the same.

[0075] Such as Figure 4 As shown, in the heating container 9, the baffle plates 9g-9i which are parallel to the center axis of the hollow cylindrical member 9c are each plural, and in this embodiment, there are three pieces each. The baffles 9g to 9i are concentrically arranged around the central axis of the hollow cylindrical member 9c. The intervals between the respective baffles 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap