Method for purifying copper electrolyte with minimal chemical reacting dose

A technology of copper electrolyte and chemical reaction, applied in electrolysis process, electrolysis components, cells, etc., to achieve low energy consumption, avoid invalid removal, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The blister copper plate obtains pure copper through electrolysis. During the electrolysis process, it is deposited as high-purity copper as the copper transfers from the anode to the cathode on the electrode. Because blister copper contains impurity metals such as arsenic and nickel, these impurities remain in the electrolyte during the electrolysis process. With the accumulation of impurities, high power consumption, chemical composition and quality decline, and chemical reactions are large. Based on this situation, the present invention adopts the following methods and steps to purify the copper electrolyte with the smallest amount of chemical reaction.

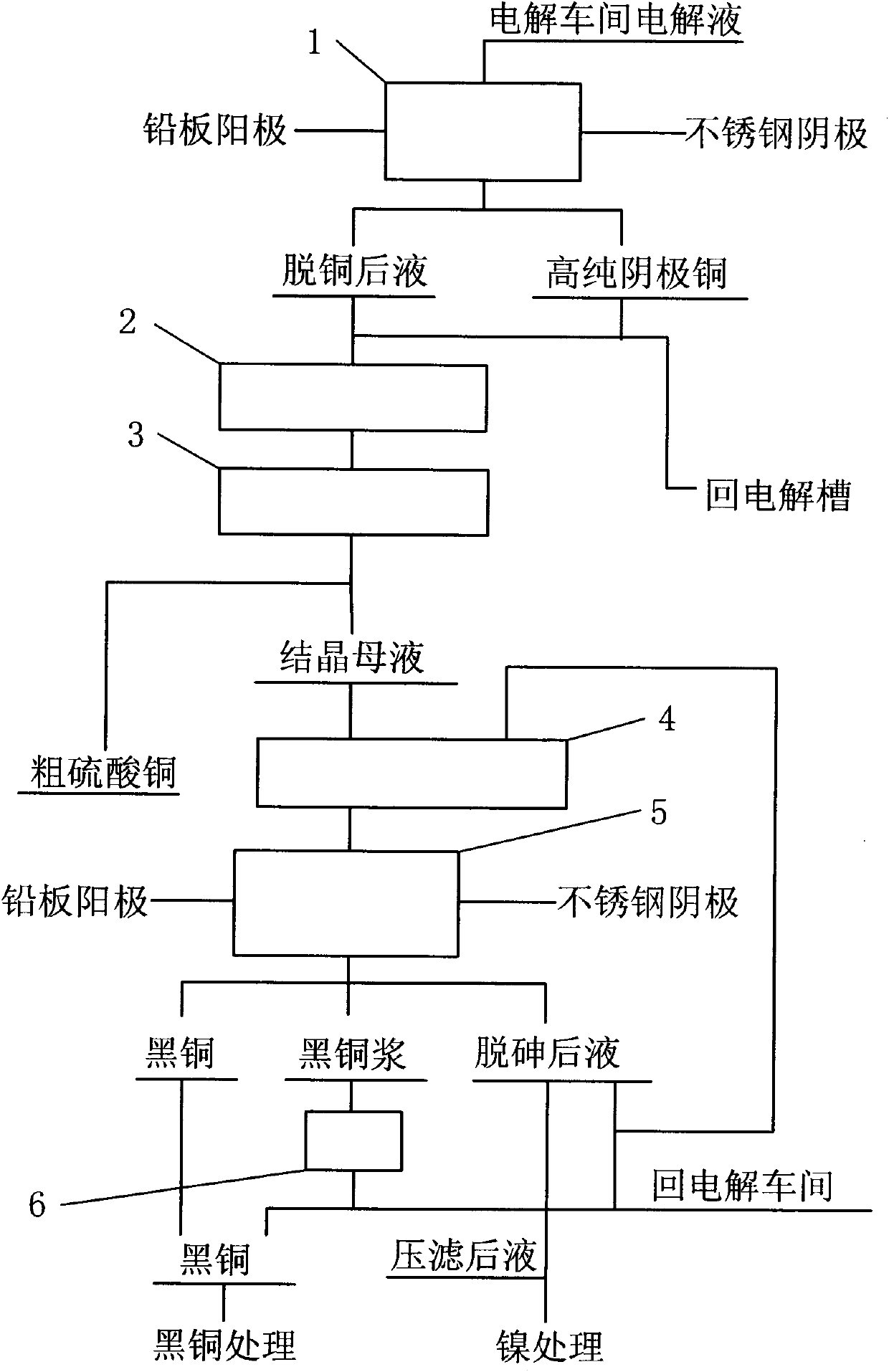

[0020] Below figure 1 Detailed description of the process flow shown

[0021] 1. Electroproduct copper removal step 1: Inject the copper electrolyte from the electrolysis workshop into the copper removal electrolytic cell, use the lead plate as the anode and the stainless steel plate as the cathode, and apply direct cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com