Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, wheels, transportation and packaging, etc., which can solve the problems of poor sealing performance in the shoulder area, insufficient performance of anti-noise performance, and inability to perform puncture sealing functions, etc. Achieve good anti-noise performance and ensure the effect of porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

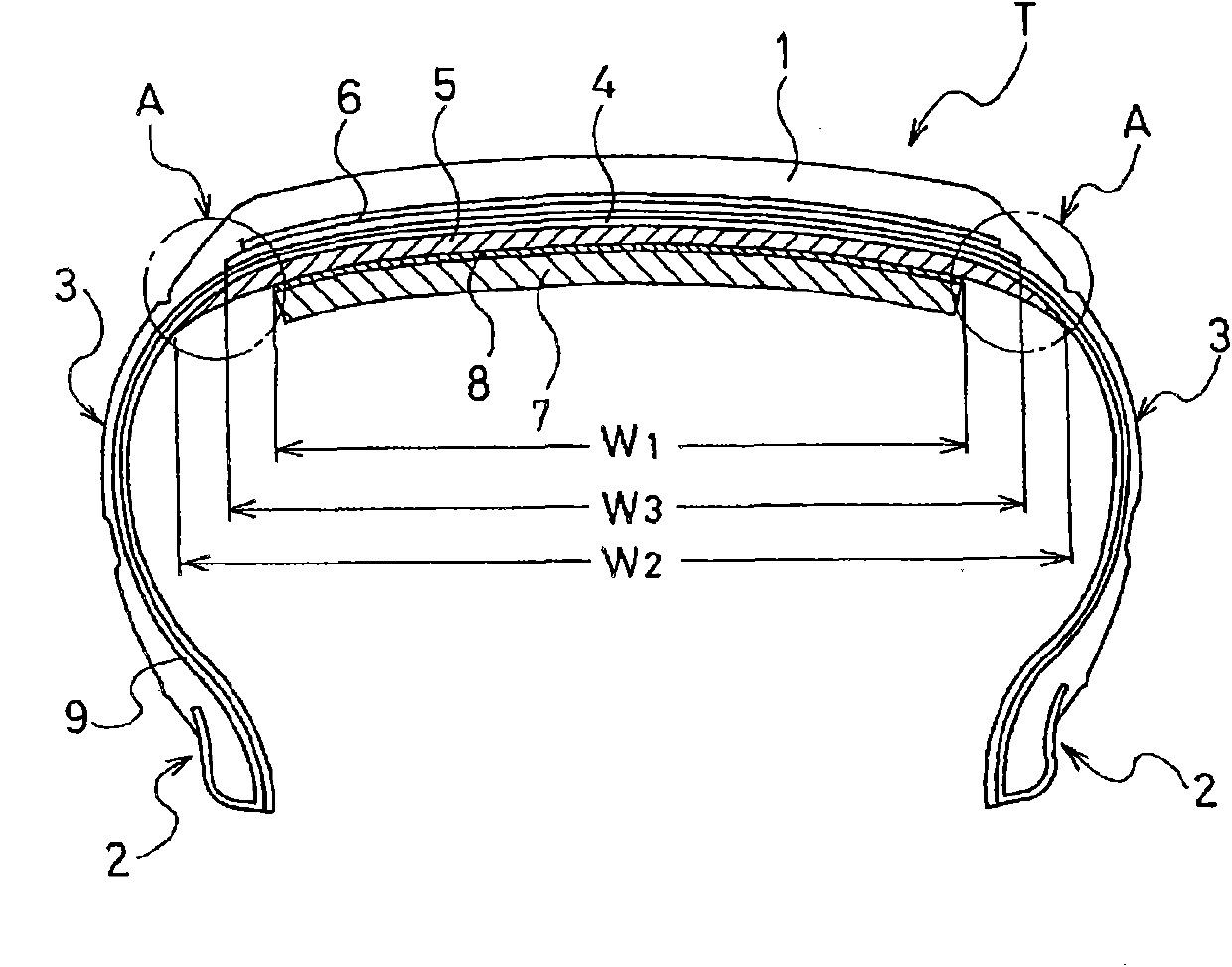

[0072] Prepare the pneumatic tire of the embodiment of the present invention 1, its parameter is: tire ruler 195 / 65R15ES300, tire structure such as figure 1 As shown, the inner circumference of the tire = 1887mm, the maximum width of the belt layer W 3 =165mm, sealing layer width W 2 =160mm (thickness 3.5mm, mass 750g), sound-absorbing layer width W 1 =130mm (thickness 15mm, mass 100g).

[0073] The sound-absorbing layer of the pneumatic tire in Example 1 is made of polyurethane foam with continuous pores, and an isolation layer containing thermoplastic elastomer resin and having a thickness of 0.1 mm is arranged outside the sound-absorbing layer. Furthermore, the relationship between the mass Ms per unit circumferential length of the sealing layer and the mass Ma per unit circumferential length of the sound absorbing layer is Ma / Ms=0.13.

[0074] As Comparative Example 1, a pneumatic tire in which a sound absorbing layer and an insulating layer were not provided in the tir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com