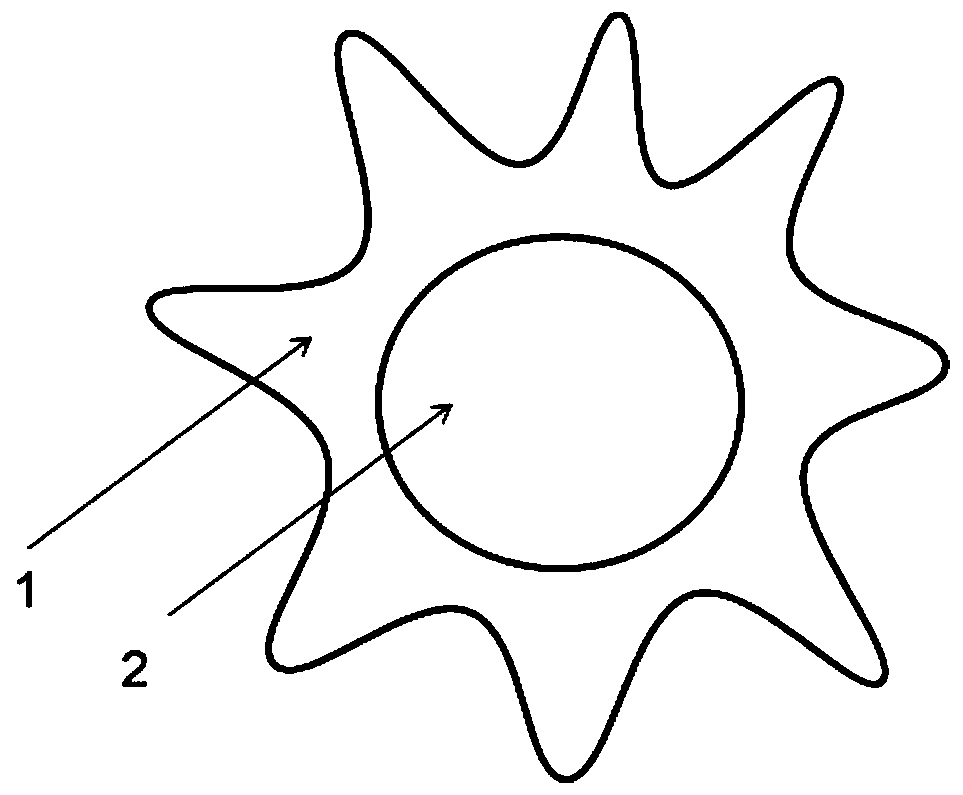

Preparation method of hollow fiber ceramic oxygen permeable membrane with petal-shaped cross section

An oxygen-permeable membrane and cross-section technology, which is applied in the field of preparation of hollow fiber ceramic oxygen-permeable membranes, can solve the problems of thick membrane thickness, low separation efficiency, and low surface reaction exchange area, so as to increase the external surface area and promote the surface reaction. , the effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the petal-shaped hollow fiber ceramic oxygen-permeable membrane comprises the following steps:

[0048] (1) Preparation of polymer solution

[0049] Dissolve 12.5g of polyethersulfone, 0.1g of polyacrylamide, and 1g of polyvinylpyrrolidone in 50g of N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.1 g of polyacrylamide is dissolved in 3 g of water, and then added to 10 g of ethylene glycol to form a mixed solution.

[0050] (2) Preparation of ceramic-polymer casting solution

[0051] 155g La 0.6 Sr 0.4co 0.2 Fe 0.8 o 3-δ Add the ceramic powder to 76.6 g of the polymer solution obtained in step (1), and fully stir for 24 hours to completely and evenly disperse it in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 25500 MPa s; The average particle size of the ceramic powder is 1 μm.

[0052] (3) Preparation of hollow fiber ceram...

Embodiment 2

[0057] The preparation method of the petal-shaped hollow fiber ceramic oxygen-permeable membrane comprises the following steps:

[0058] (1) Preparation of polymer solution

[0059] Dissolve 12.5g polyethersulfone, 0.5g polyacrylamide, 2g polyvinyl butyral in 50g N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.5 g of polyacrylamide is dissolved in 5 g of water, and then added to 20 g of ethylene glycol to form a mixed solution.

[0060] (2) Preparation of ceramic-polymer casting solution

[0061] 157.5g Ba 0.5 Sr 0.5 co 0.8 Fe 0.2 o 3-δ Add the ceramic powder to 81g of the polymer solution obtained in step (1), and fully stir for 30 hours to make it completely and evenly dispersed in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 30400MPa·s; The average particle size of the ceramic powder is 5 μm.

[0062] (3) Preparation of hollow fiber ceramic oxygen perm...

Embodiment 3

[0067] The preparation method of the petal-shaped hollow fiber ceramic oxygen-permeable membrane comprises the following steps:

[0068] (1) Preparation of polymer solution

[0069] Dissolve 12.5g of polysulfone, 0.5g of polyacrylamide, and 5g of polyacrylamide in 50g of N,N-dimethylformamide-d 7 , to obtain a polymer solution; wherein polyacrylamide is added in the form of a mixed solution: 0.5 g of polyacrylamide is dissolved in 5 g of water, and then added to 25 g of ethylene glycol to form a mixed solution.

[0070] (2) Preparation of ceramic-polymer casting solution

[0071] 200g Ba 0.5 Sr 0 .5Co 0.8 Fe 0.2 o 3-δ Add the ceramic powder to 98g of the polymer solution obtained in step (1), and stir it fully for 30 hours to completely and evenly disperse it in the polymer solution to form a ceramic-polymer casting solution with a viscosity of 38000MPa·s; The average particle size of the ceramic powder is 6 μm.

[0072] (3) Preparation of hollow fiber ceramic oxygen p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com