Enhanced milling device of CNC lathe

A milling device and enhanced technology, which can be applied to the milling device, driving device, milling machine equipment, etc. that can be installed on the machine tool, can solve the problem of insufficient cutting tools, achieve the effect of small vibration, good rigidity, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

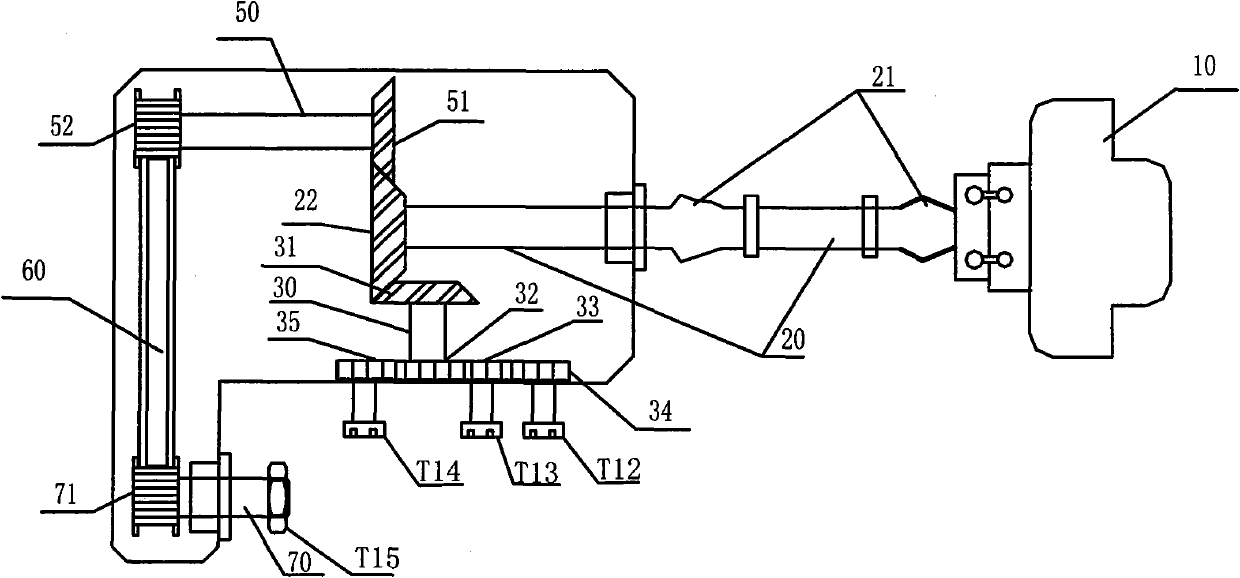

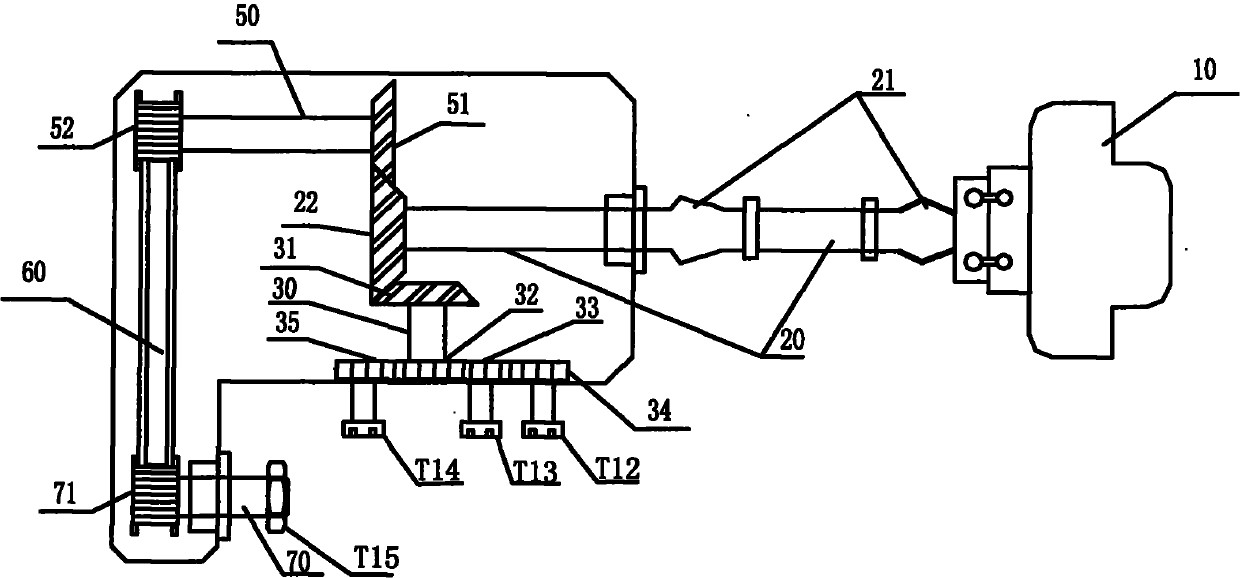

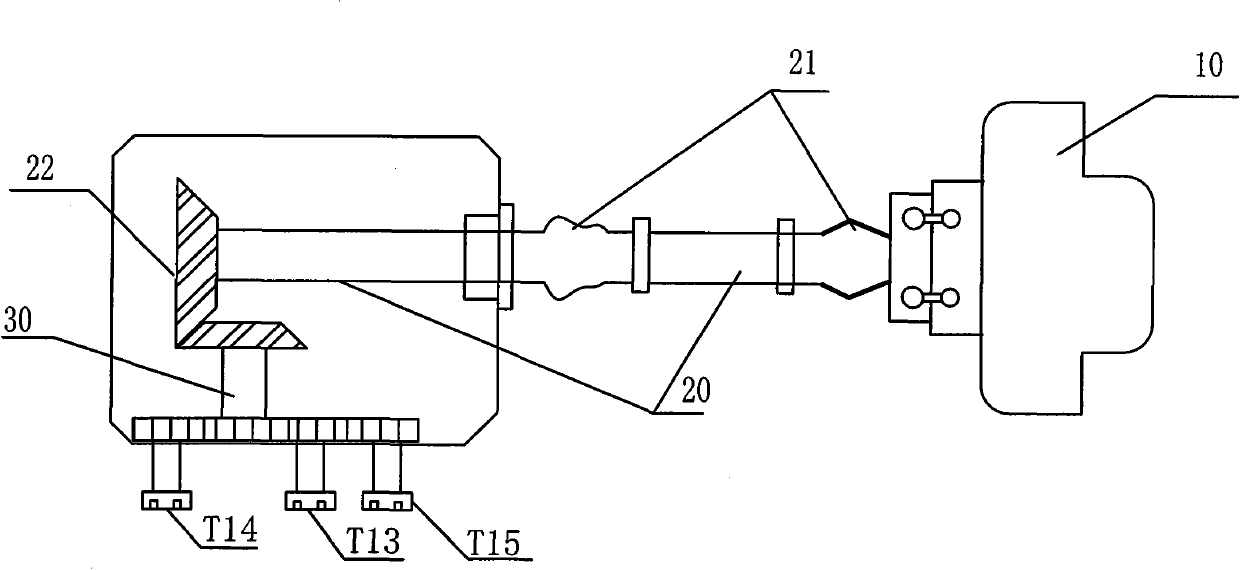

[0017] see figure 2 , the present invention includes a milling cutter, a servo motor 10, a first transmission shaft 20, a universal joint 21, a second transmission shaft 50, a first sector gear 22, and a tool holder shaft core 70; the power shaft of the servo motor 10 passes through the universal joint Joint 21 is connected to one end of the first transmission shaft 20, and the first transmission shaft 20 is provided with two transmission shafts, which are connected by universal joints 21 between the two transmission shafts, and the second transmission shaft is installed at the other end of the first transmission shaft 20. A sector gear 22; the first sector gear 22 is connected with the milling tool through the milling shaft 30 to drive the milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com