Pneumatic parallel gate valve

A gate valve and gate technology, applied in sliding valves, balance valves, valve details, etc., can solve the problems of high-pressure pneumatic gate valve blanks, etc., and achieve the effects of good wear resistance, safe use, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

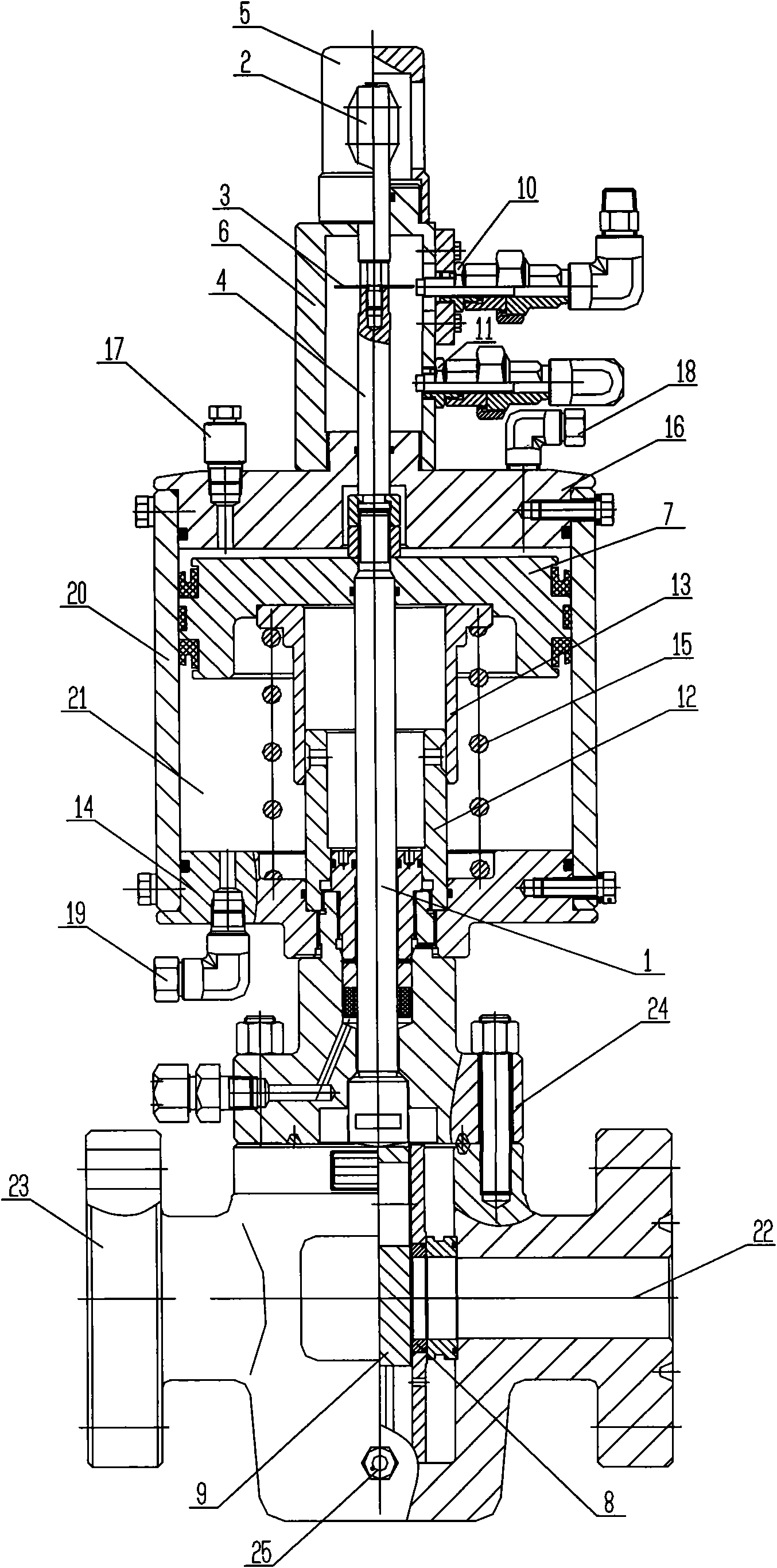

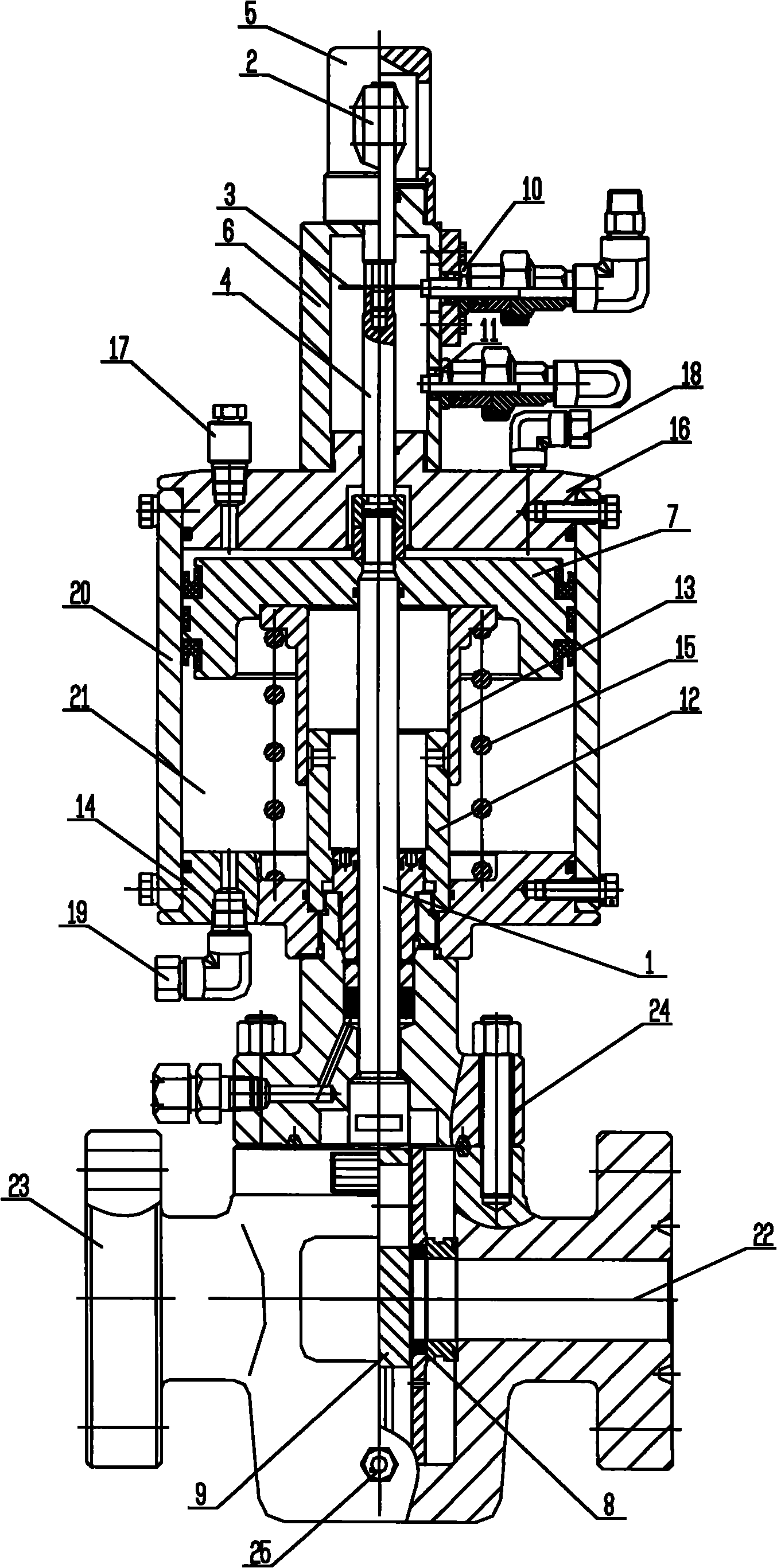

[0015] Below in conjunction with accompanying drawing, further illustrate the present invention through embodiment.

[0016] like figure 1 As shown, in the pneumatic parallel gate valve of the present invention, the upper part of the valve stem 1 braked by the piston 7 is sequentially connected with the display rod 2, the induction plate 3, and the connecting rod 4, and the display rod 2 is located in the display sheath 5 Inside, the induction plate 3 and the connecting rod 4 are located in the sheath 6, and the lower end of the valve stem 1 is connected with the gate plate 9 which is in sealing contact with the valve seat 8; Sensor 10 and lower sensor 11; the cylinder where piston 7 is located is located below the sheath 5, the lower end of the piston 7 is connected with a sliding sleeve 13 socketed with the guide sleeve 12, and the outer edge of the sliding sleeve 13 is connected with the lower cylinder cover 14 of the cylinder. The spring 15 arranged straight; the upper cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com