Method for two-way hoisting construction of converter tower steel structure

A construction method and steel structure technology, which is applied in the direction of building structure, construction, and building material processing, can solve the problems of slow construction progress, high construction cost, and long construction period, so as to improve efficiency, shorten construction period, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

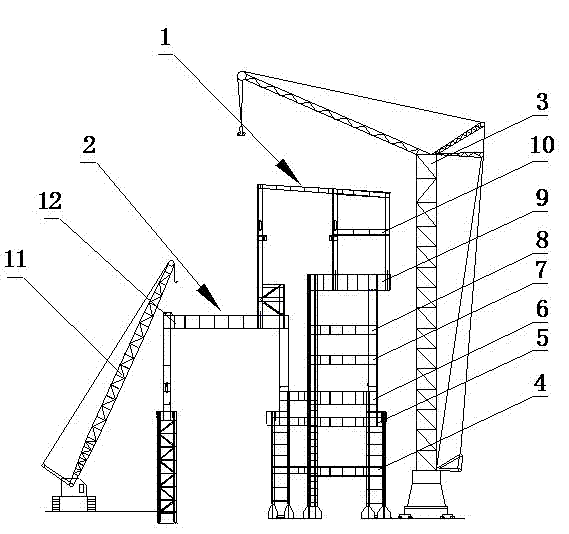

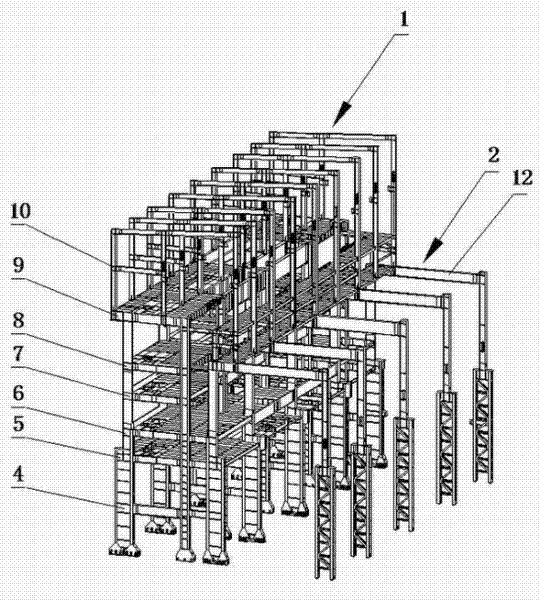

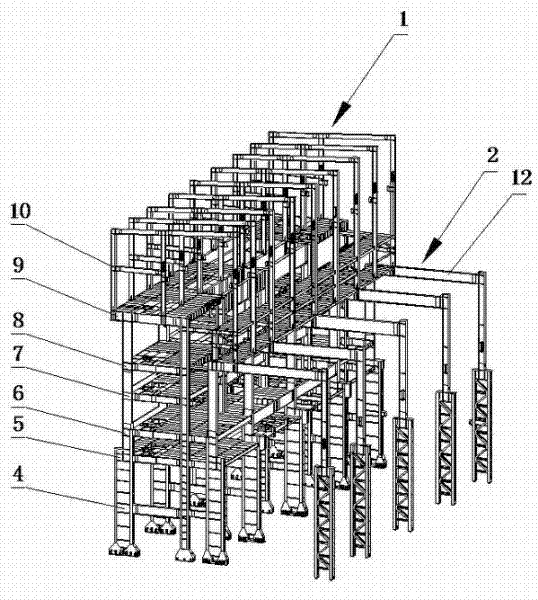

[0021] figure 1 It is a schematic diagram of the hoisting of the converter tower, figure 2 It is the steel structure diagram of the converter tower, as shown in the figure. A two-way hoisting construction method for a steel structure of a converter tower. The converter tower has seven floors, including a converter span 1 and a feeding span 2. The construction includes the following steps:

[0022] a. Use tower crane 3 to hoist the steel column from the first floor to the fourth floor 7. The frame beam of the fourth floor 7 is hoisted by the truck crane. After the frame beam of the fourth floor 7 is installed and welded, immediately lay the platform slab and steel column During the upward construction, the main frame beams are installed to form a steel bent frame, which forms a stable unit system in space, meets the rigidity and stability requirements of the upward installation of steel columns, and ensures the safety of construction. The fourth floor 7 divides the entire se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com