Thread trapper device for a spindle of a spinning or thread machine

A technology of twisting machine and spinning machine, applied in spinning machine, continuous winding spinning machine, transportation and packaging, etc., can solve problems such as vibration insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

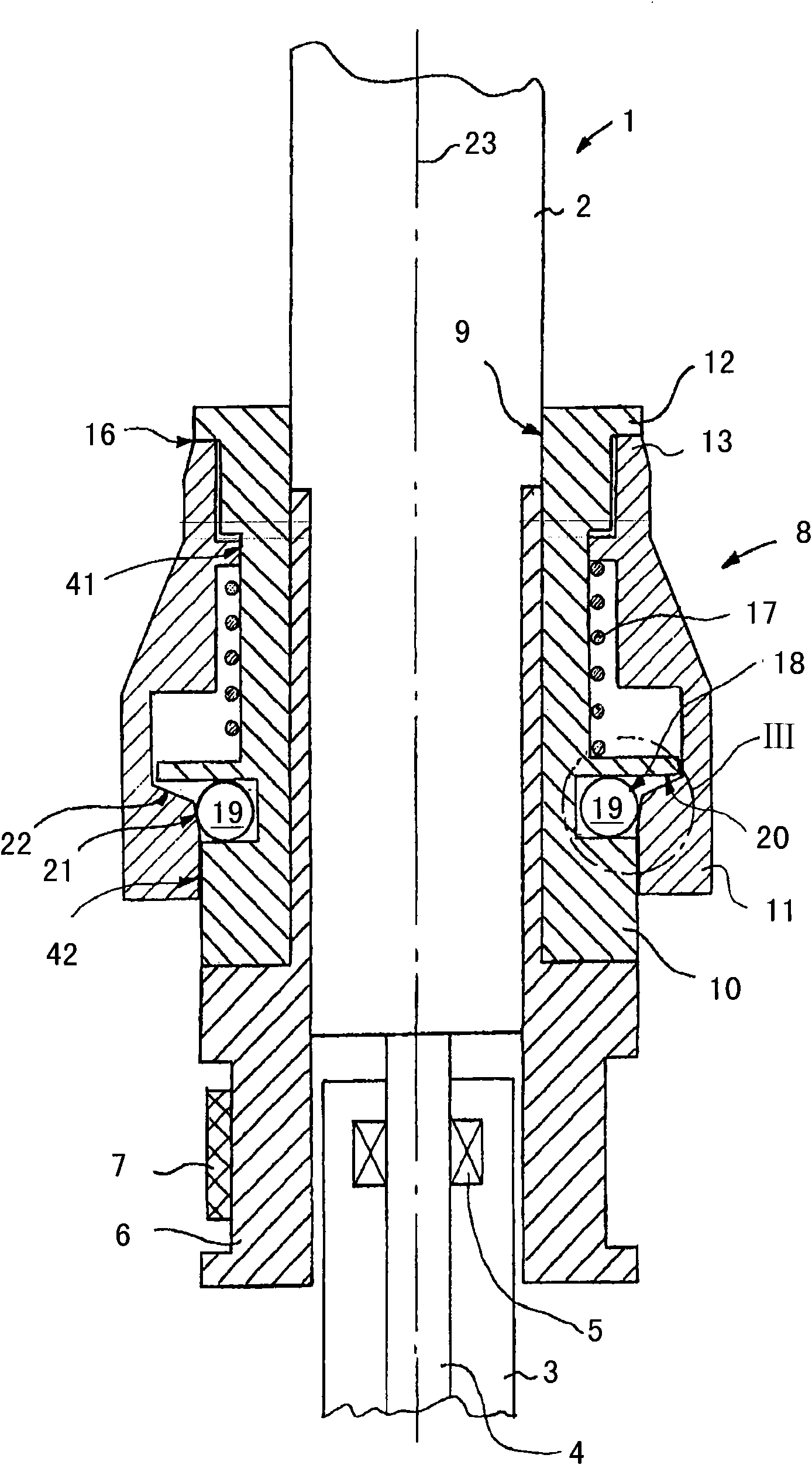

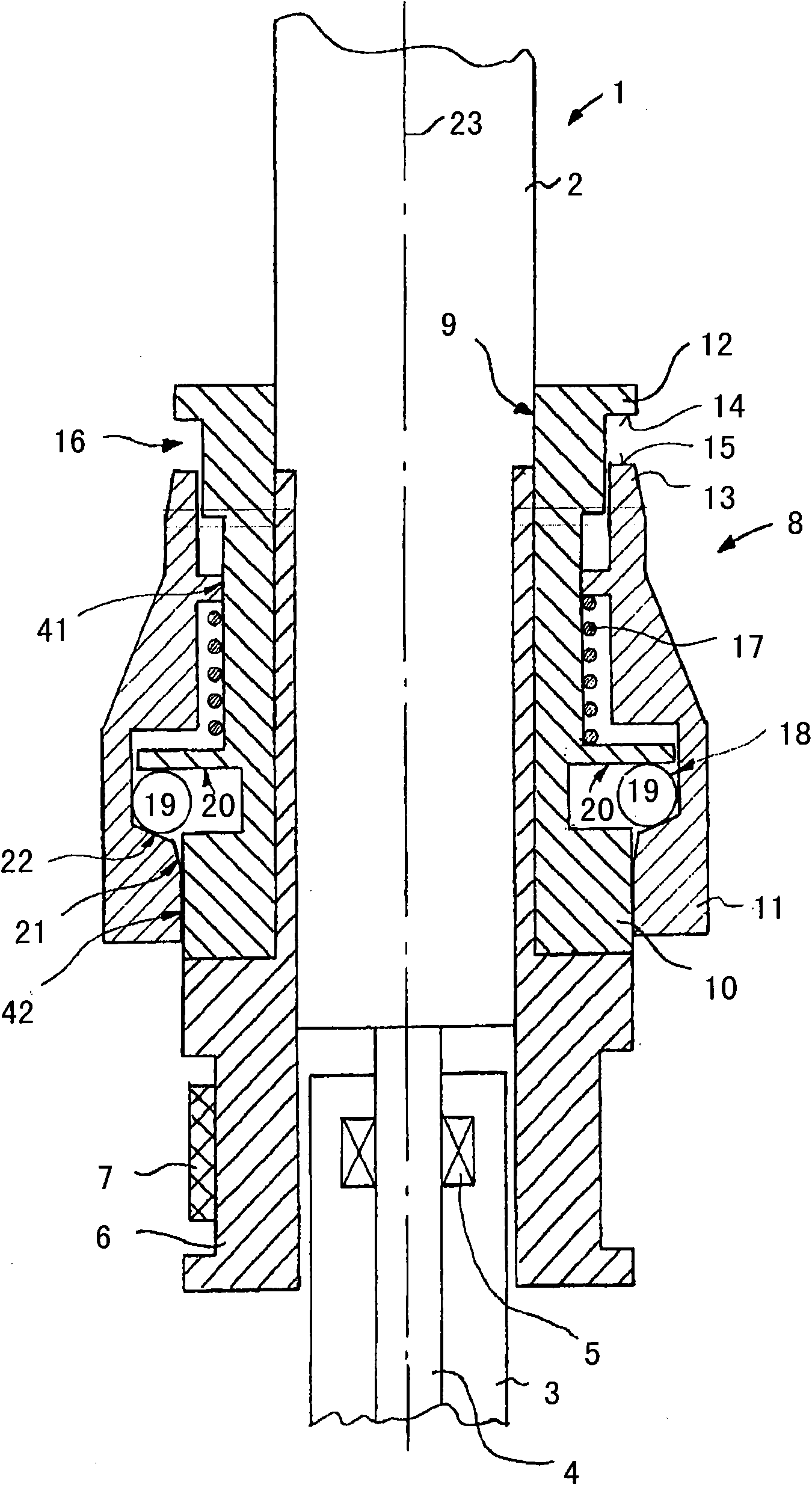

[0023] figure 1 A spindle 1 of a spinning or twisting machine is shown in . The spindle 1 consists of a rotating upper part 2 and a non-rotating bearing housing 3 , which is fixed stationary on a not shown spindle rail. The upper part 2 has a shaft 4 which rotates therewith, which is mounted in a bearing housing 3 in journal bearings 5 and a not shown end bearing. The upper part 2 contains a spindle 6 via which the upper part can be driven with a belt 7 .

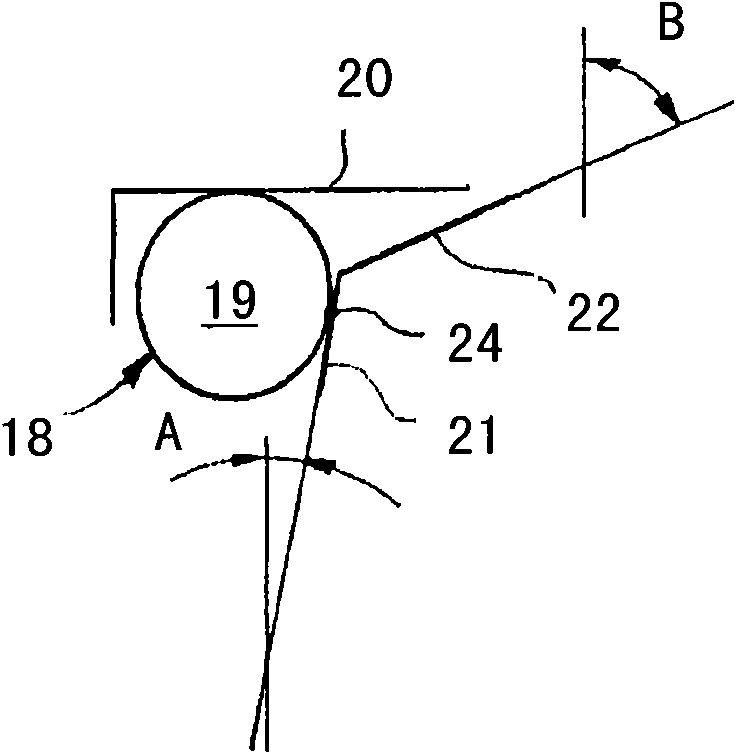

[0024]The top of the spindle disk 6 is provided with a clamping device 8 . The yarn clamping device 8 is mounted on the spindle upper part 2 by means of a mounting frame 9 . The clamping device 8 is preferably fastened detachably to the upper part 2 so that it can be easily replaced in case of a problem. Above the yarn clamping device 8, the upper part 2 can accommodate a bobbin, not shown, on which bobbin the produced yarn is wound into yarn bobbins. The winding process is carried out in a known manner with a liftab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com