Closed photo bioreactor for enhancing light energy utilization rate of microalgae mass culture

A photobioreactor and closed technology, applied in the biological field, can solve the problems of difficulty in ensuring algae cell illumination, disordered mixing of algae cells, and high manufacturing costs, and achieve the goal of improving light energy utilization, expanding production scale, and increasing production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

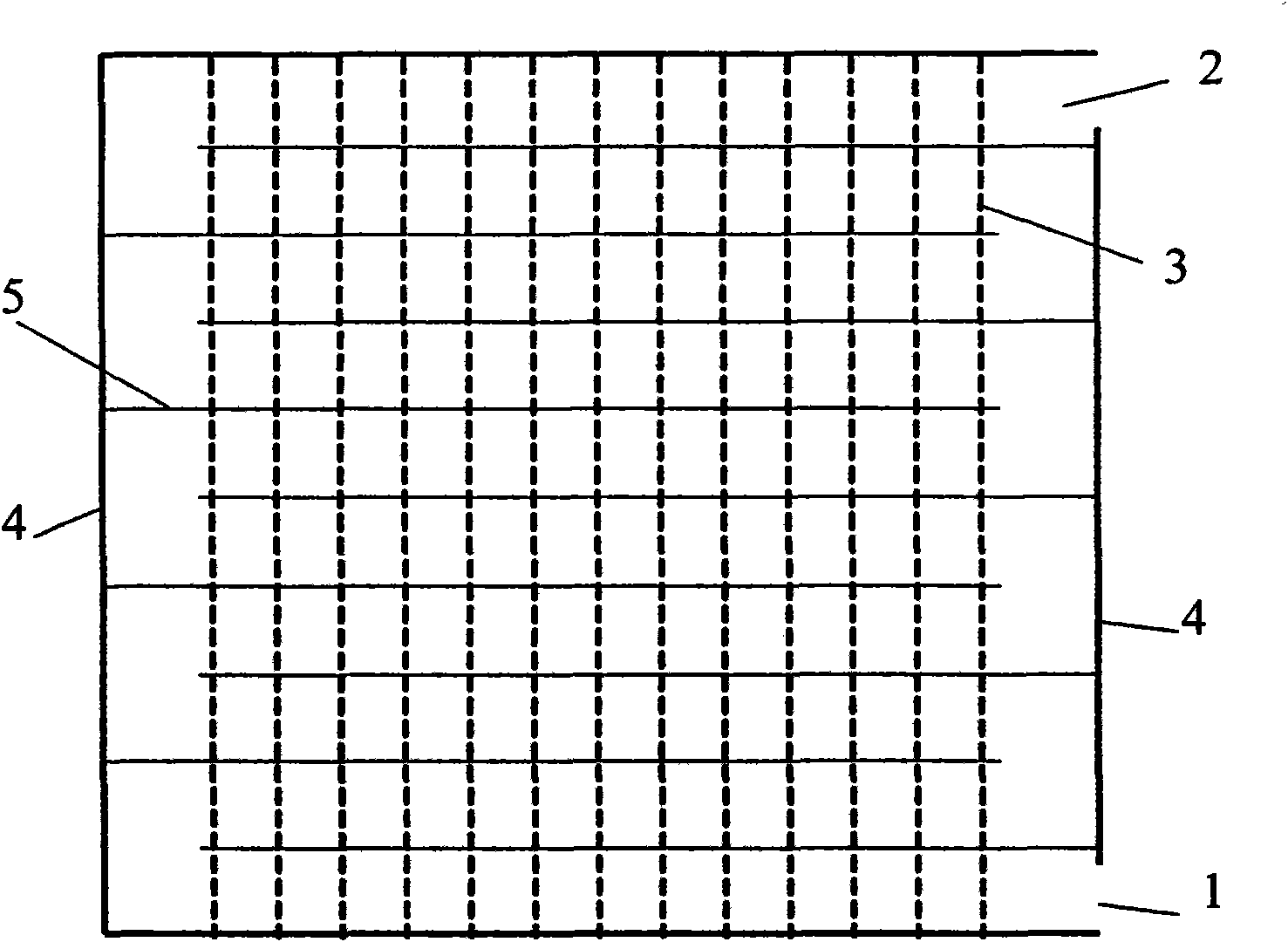

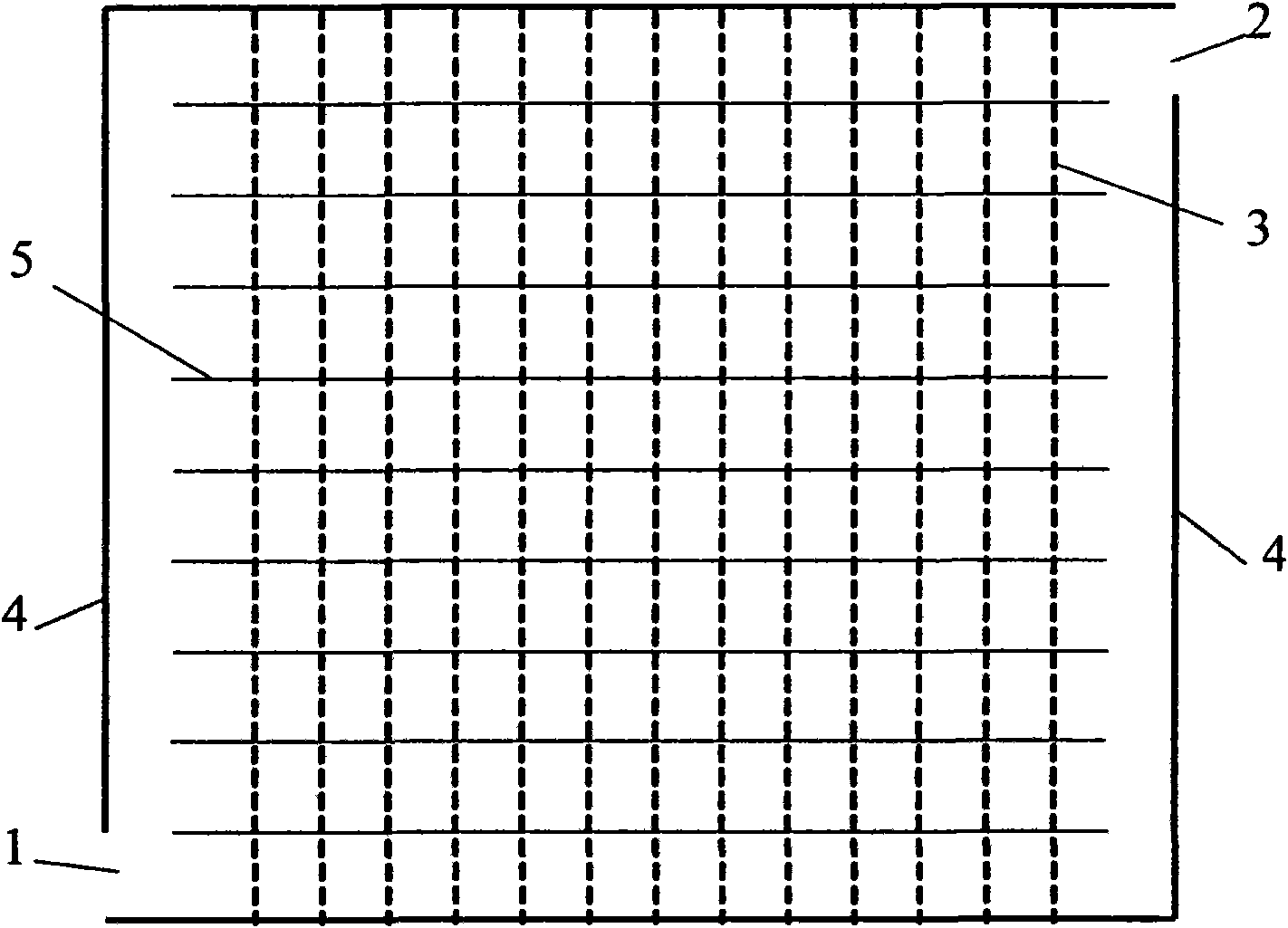

[0052] Spirulina was cultivated outdoors under natural light. The plate-type photobioreactor of the constructed culture system is placed horizontally, and the manufacturing material is a plexiglass plate, the thickness of the upper and lower panels is 2mm, the thickness of the end panel 4 and the rib plate 5 are both 2mm, and the length of the rib plate 5 is 80cm. The size of the plate-type photobioreactor is: 1m in length, 1.022m in width, and 2cm between the inner surfaces of the upper and lower panels. Adhere to the inner side of the upper panel and paste a baffle 3 with a rectangular cross-section made of plexiglass plate material, the direction of the baffle is perpendicular to the flow channel, the distance between the baffles is 8mm, the height of the baffle is 3mm, and the thickness of the baffle is 2mm. The length of the baffles is 10 cm (equal to the width of the flow channel), and 90 baffles are installed in each flow channel (the area between the baffles covers abo...

Embodiment 2

[0061] Spirulina was cultivated under natural light. Other conditions were the same as in Example 1, except that the height of the rectangular baffle inside the upper panel of the plate-type photobioreactor was 1 mm, and the distance between the rectangular baffles was 5 mm.

[0062] The cultivation process lasted for 30 days, and the area yield of Spirulina was about 33g / m 2 .d, higher than the area productivity (24g / m2) of comparative example 1 under the same culture condition in the plate photobioreactor without baffle 2 .d), indicating that the light energy utilization rate of the algae cells is significantly improved.

Embodiment 3

[0064] Spirulina was cultivated under natural light. Other conditions were the same as in Example 1, except that the height of the rectangular baffle inside the upper panel of the plate-type photobioreactor was 8 mm, and the distance between the rectangular baffles was 42 mm.

[0065] The cultivation process lasted for 30 days, and the area yield of Spirulina was about 36g / m 2 .d, higher than the area productivity (24g / m2) of comparative example 1 under the same culture condition in the plate photobioreactor without baffle 2 .d), indicating that the light energy utilization rate of the algae cells is significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volumetric yield | aaaaa | aaaaa |

| Volumetric yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com