Extension sleeve type elevator and automobile maintenance elevator

A technology of telescopic sleeves and lifts, which is applied in the direction of lifting frames, lifting devices, lifting equipment safety devices, etc., can solve the problems of increasing the width of the pit, not preventing rotation, and reliability, and achieves the reduction of working oil volume and large Height lift and space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

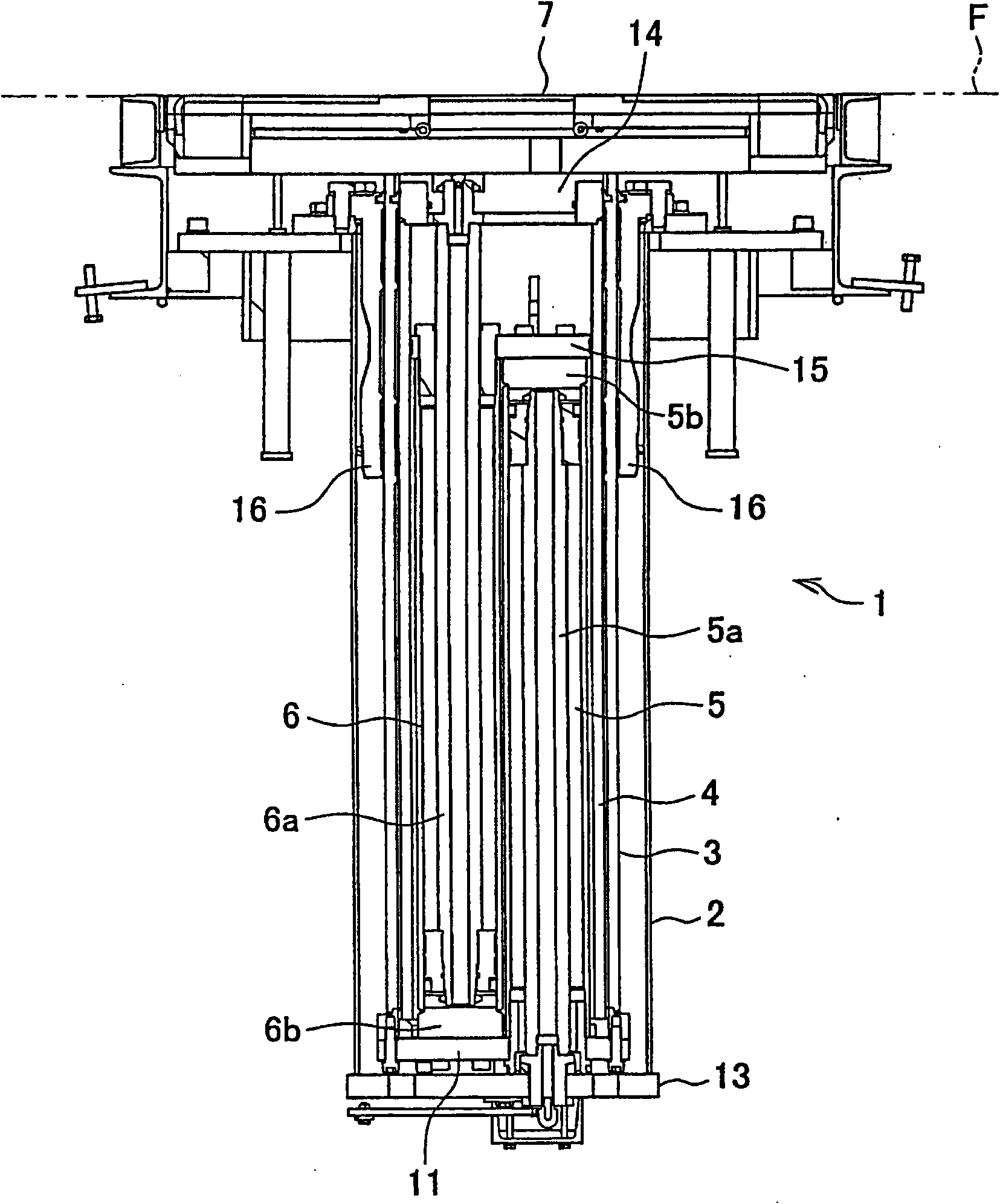

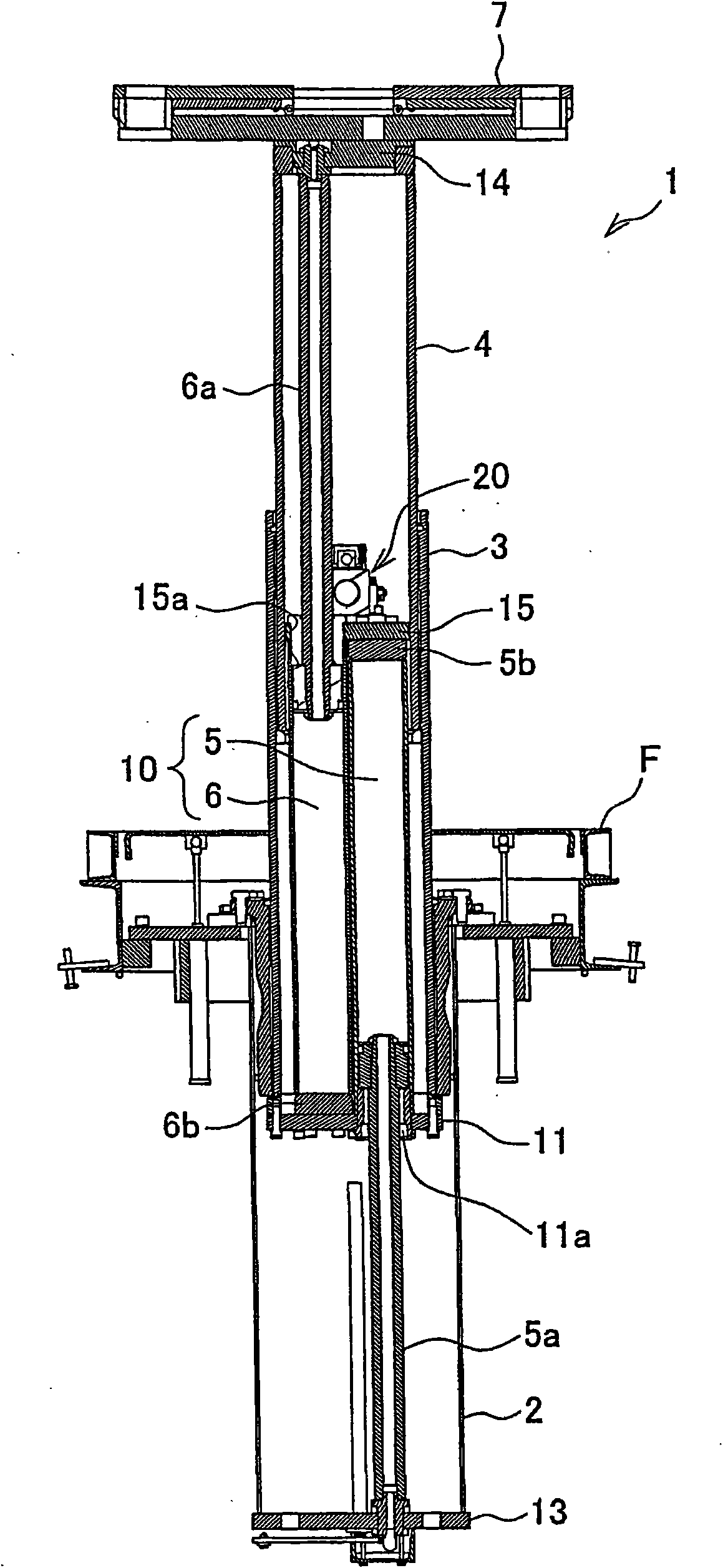

[0051] The specific implementation manner of the present invention will be described in detail below according to the accompanying drawings. Figure 1 to Figure 5 Showing an example of the car maintenance lift of the present invention, figure 1 It is a cross-sectional explanatory drawing viewed from the front of a telescopic telescopic lifter constituting the lifting device of the lifter for automobile maintenance, figure 2 It is a cross-sectional illustration viewed from its right side, image 3 It is a cross-sectional explanatory diagram viewed from the right side with the telescopic telescopic elevator in an extended state, Figure 4 It is a cross-sectional explanatory drawing seen from the back in the same stretched state, Figure 5 It is an explanatory top view of the telescopic telescopic elevator.

[0052] A plurality of (for example, 4) telescopic telescopic elevators 1 are set in pits that are recessed on the working ground F and are not shown in the figure to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com