Method for preparing montmorillonite forming adsorbent

A technology of adsorbent and montmorillonite, which is applied in the direction of chemical instruments and methods, adsorption water/sewage treatment, silicate, etc., can solve the problems of reduced adsorption performance, high temperature, and easily damaged structure, so as to reduce adverse effects, The effect of reducing swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

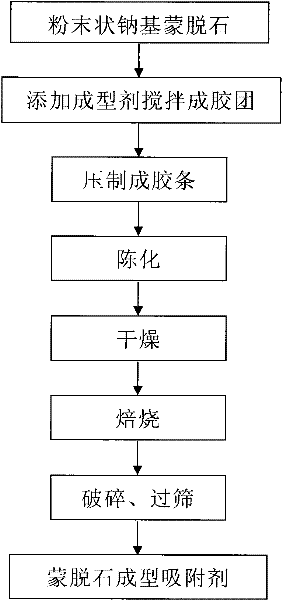

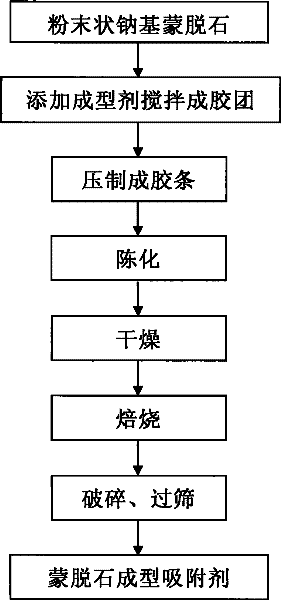

Method used

Image

Examples

Embodiment 1

[0020] (1) adopting purity is 90%, and cation exchange capacity CEC is 70mmol / 100g, and colloid price is 60ml / g, and expansion times is 10ml / g, and blue absorbing amount is the powdery sodium montmorillonite of 35g / 100g;

[0021] (2) Add molding agent to powdery sodium montmorillonite, and add appropriate amount of water to stir into micelles, the mass ratio of molding agent to powdery sodium montmorillonite is 5:100; place micelles in extrusion In the molding machine, it is pressed into rubber strips at normal temperature; the molding agent is NaHCO 3 , NaOH, KOH or Na 2 CO 3 ;

[0022] (3) Aging the rubber strip for 2 hours at room temperature with a relative humidity of 50%, so that the montmorillonite in the rubber strip fully reacts with the forming agent and combines compactly;

[0023] (4) Place the aged rubber strip in a drying oven with a temperature of 100° C. for 2 hours;

[0024] (5) Put the dried strips in a high-temperature furnace, bake them for 50 minutes a...

Embodiment 2

[0030] (1) adopting purity is 92%, and cation exchange capacity CEC is 80mmol / 100g, and colloid price is 80ml / g, and expansion times is 10ml / g, and blue absorption amount is the powdery sodium montmorillonite of 38g / 100g;

[0031] (2) Add molding agent to powdery sodium montmorillonite, and add appropriate amount of water to stir into micelles, the mass ratio of molding agent to powdery sodium montmorillonite is 11:100; place micelles in extrusion In the molding machine, it is pressed into rubber strips at normal temperature; the molding agent is NaHCO 3 , NaOH, KOH or Na 2 CO 3 ;

[0032] (3) Aging the rubber strip at room temperature with a relative humidity of 30% for 2.5 hours, so that the montmorillonite in the rubber strip and the molding agent fully react and combine densely;

[0033] (4) Dry the aged strips in a drying oven at a temperature of 110°C for 2.5 hours;

[0034] (5) Put the dried rubber strip in a high-temperature furnace, bake it at 600°C for 30 minutes...

Embodiment 3

[0040] (1) adopting purity is 95%, and cation exchange capacity CEC is 75mmol / 100g, and colloid price is 60ml / g, and expansion times is 12ml / g, and blue absorption amount is the powdery sodium-based montmorillonite of 40g / 100g;

[0041] (2) Add molding agent to powdery sodium montmorillonite, and add appropriate amount of water to stir into micelles, the mass ratio of molding agent to powdery sodium montmorillonite is 3:100; place micelles in extrusion In the molding machine, it is pressed into rubber strips at normal temperature; the molding agent is NaHCO 3 , NaOH, KOH or Na 2 CO 3 ;

[0042] (3) Aging the rubber strip for 1 hour at room temperature with a relative humidity of 70%, so that the montmorillonite in the rubber strip fully reacts with the forming agent and combines compactly;

[0043] (4) Dry the aged strips in a drying oven at 120°C for 1 hour;

[0044](5) Put the dried strips in a high-temperature furnace, bake them for 40 minutes at a temperature of 500° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mana absorption | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com