Method and device for preparing dry desulfurizing agent by using carbide slag

A dry desulfurization and preparation device technology, applied in separation methods, chemical instruments and methods, calcium/strontium/barium oxides/hydroxides, etc., can solve the problems of high chloride ion concentration, complex system, poor economy, etc. Achieve the effect of simple process flow, less engineering investment and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

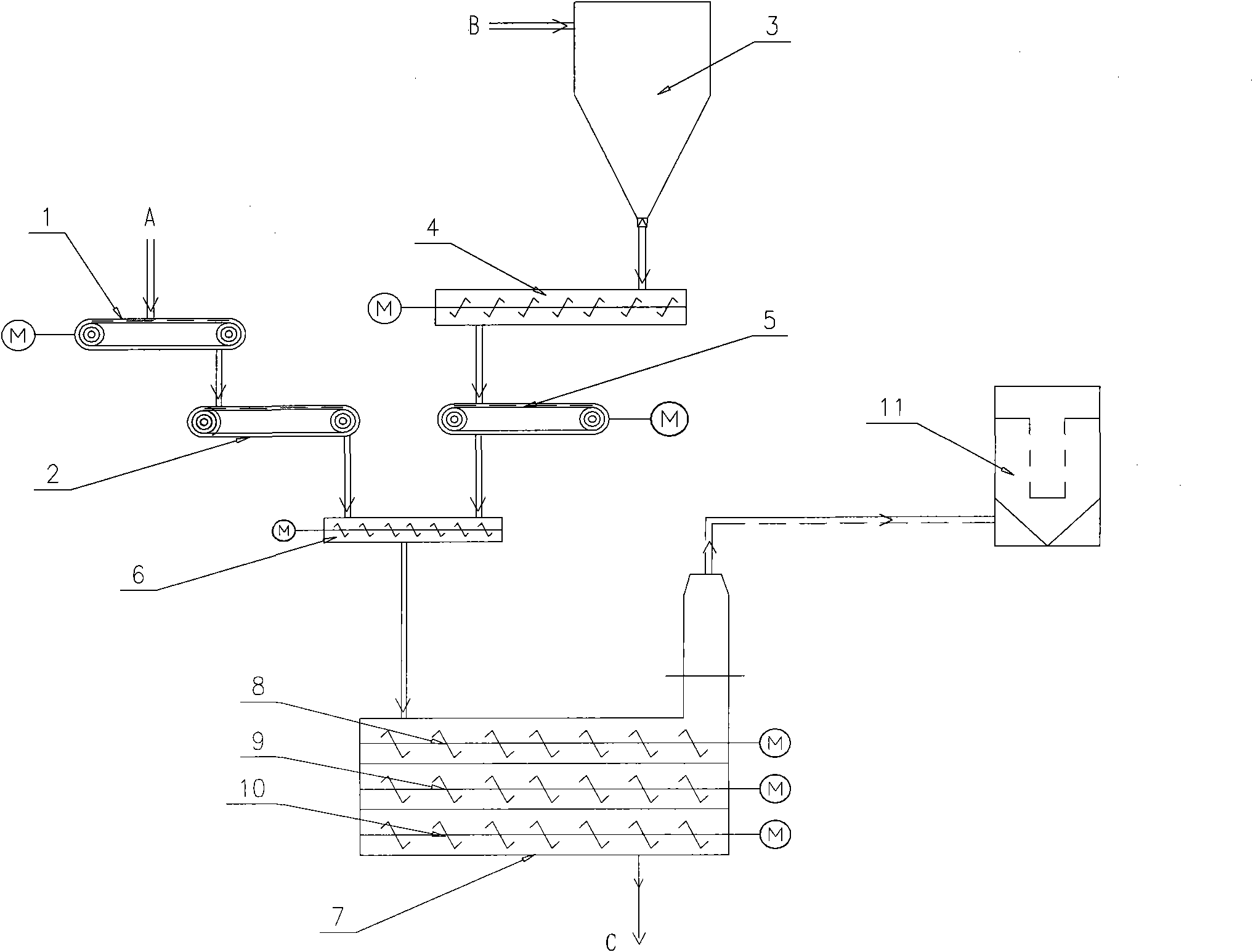

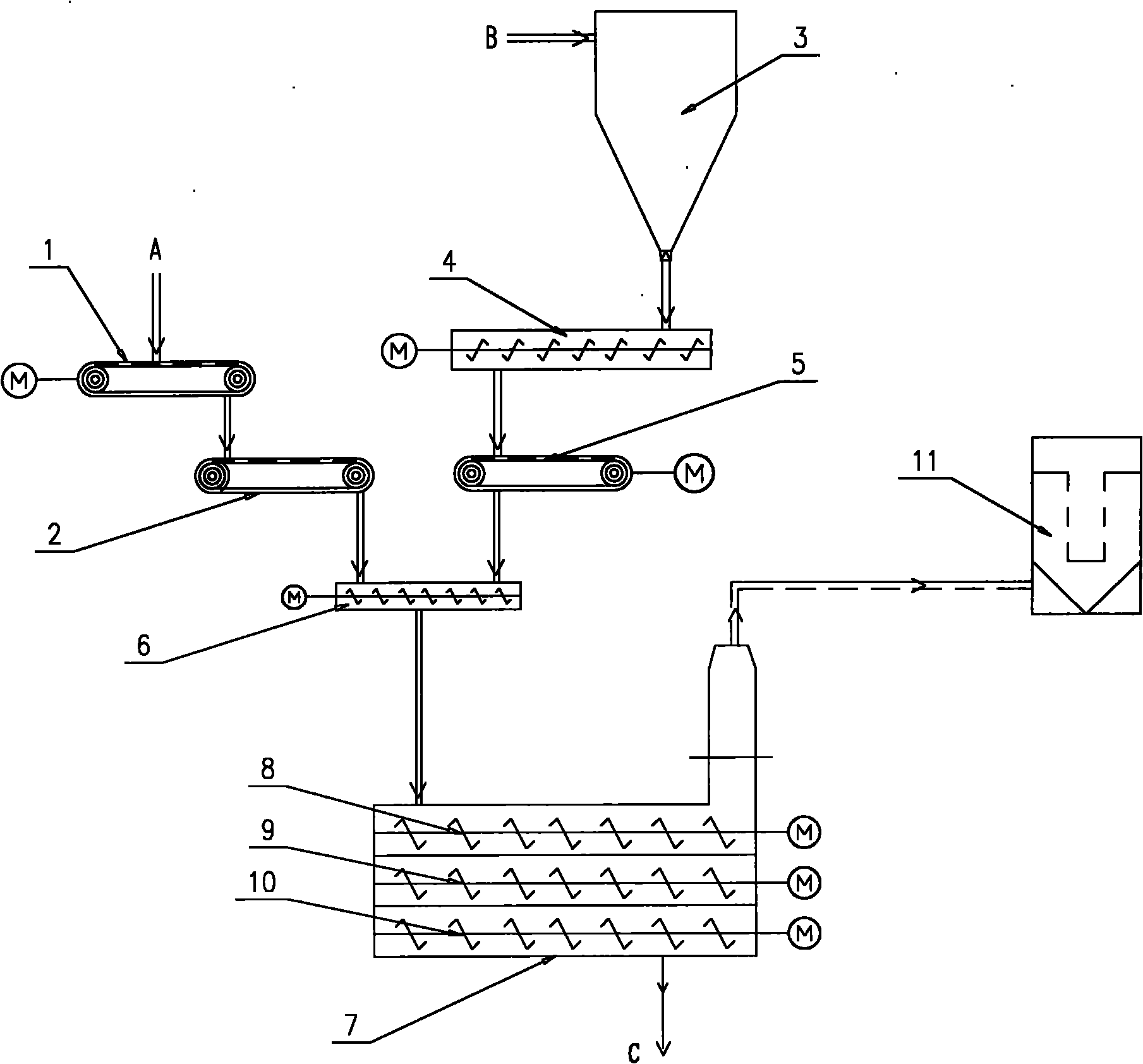

Embodiment 1

[0023] Embodiment 1: the quality of carbide slag is: Ca(OH) 2 The content is 66%, and the water content is 30%. The quality of the quicklime powder is: the CaO content is 65%, and the particle size is ≤1mm; the ratio of calcium carbide slag and quicklime powder is 1:1. Calcium carbide slag enters the quantitative feeder through the feeding funnel for weighing, and after weighing, it is sent to the pre-mixer through the belt conveyor for preliminary mixing and crushing with the quicklime quantitatively added after the quicklime bin, screw feeder and belt weighing machine . The uniformly mixed material enters the calcium carbide slag humidity setting machine. After the calcium carbide slag humidity setting and quicklime digestion reaction in the humidity setting machine for 60 minutes, the slaked lime powder is obtained. 2 Content 80%.

Embodiment 2

[0024] Embodiment 2: the quality of carbide slag is: Ca(OH) 2 The content is 60%, and the water content is 35%. The quality of the quicklime powder is: the CaO content is 85%, and the particle size is ≤1mm; the ratio of calcium carbide slag and quicklime powder is 1:0.4.

[0025] Calcium carbide slag enters the quantitative feeder through the feeding funnel for weighing, and after weighing, it is sent to the pre-mixer through the belt conveyor for preliminary mixing and crushing with the quicklime quantitatively added after the quicklime bin, screw feeder and belt weighing machine . The uniformly mixed material enters the calcium carbide slag humidity setting machine. After the calcium carbide slag humidity setting and the quicklime digestion reaction are carried out in the humidity setting machine for 60 minutes, the obtained slaked lime powder has the following qualities: 95% of the slaked lime has a particle size of less than 125um, a water content of 0.27%, and Ca(OH) 2 ...

Embodiment 3

[0026] Embodiment 3: similar to embodiment 1, the difference is that the proportioning of calcium carbide slag and unslaked lime powder is 1: 0.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com