Dust collecting barrel of novel dust collector

A technology for vacuum cleaners and dust collection buckets, which is applied in the direction of suction filters, etc., can solve the problems that affect the widespread popularization and market application prospects of vacuum cleaner products, reduce the user experience of product use, and the high price of stepping motors, so as to promote widespread popularization and market application prospects , enhance product use experience, and the effect of significant production practice significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art better understand the solution of the present invention, the present invention is further described in detail below with reference to the accompanying drawings and embodiments.

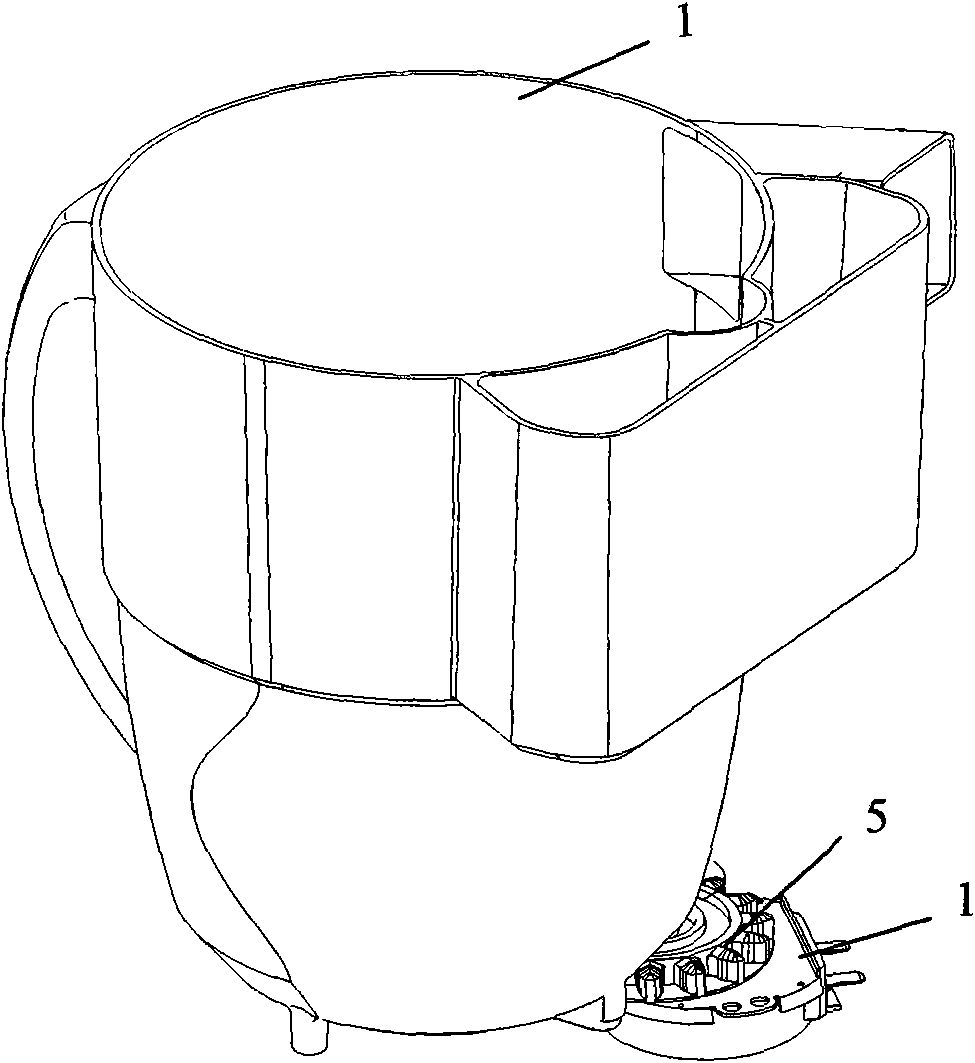

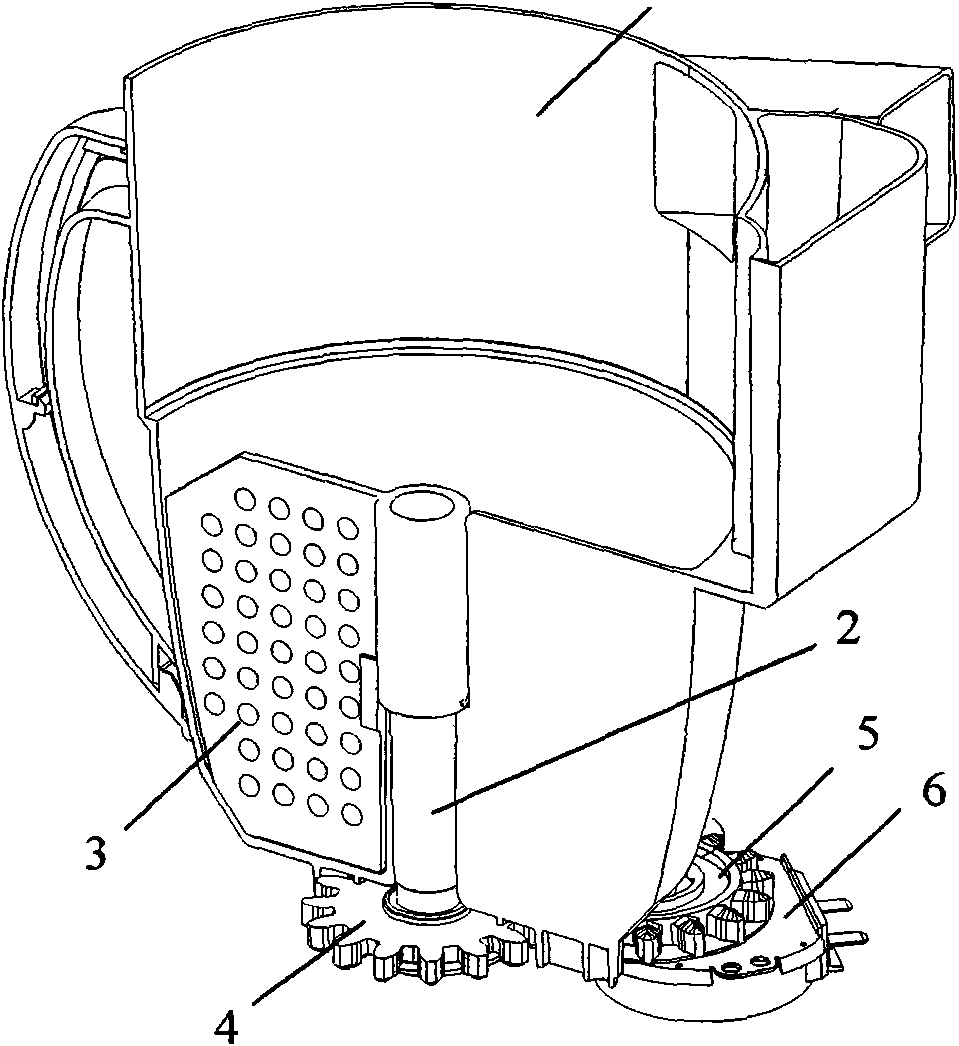

[0027] image 3 A schematic diagram of the appearance structure of the dust collecting bin in the dust collecting bucket of a new type of vacuum cleaner provided by the present invention.

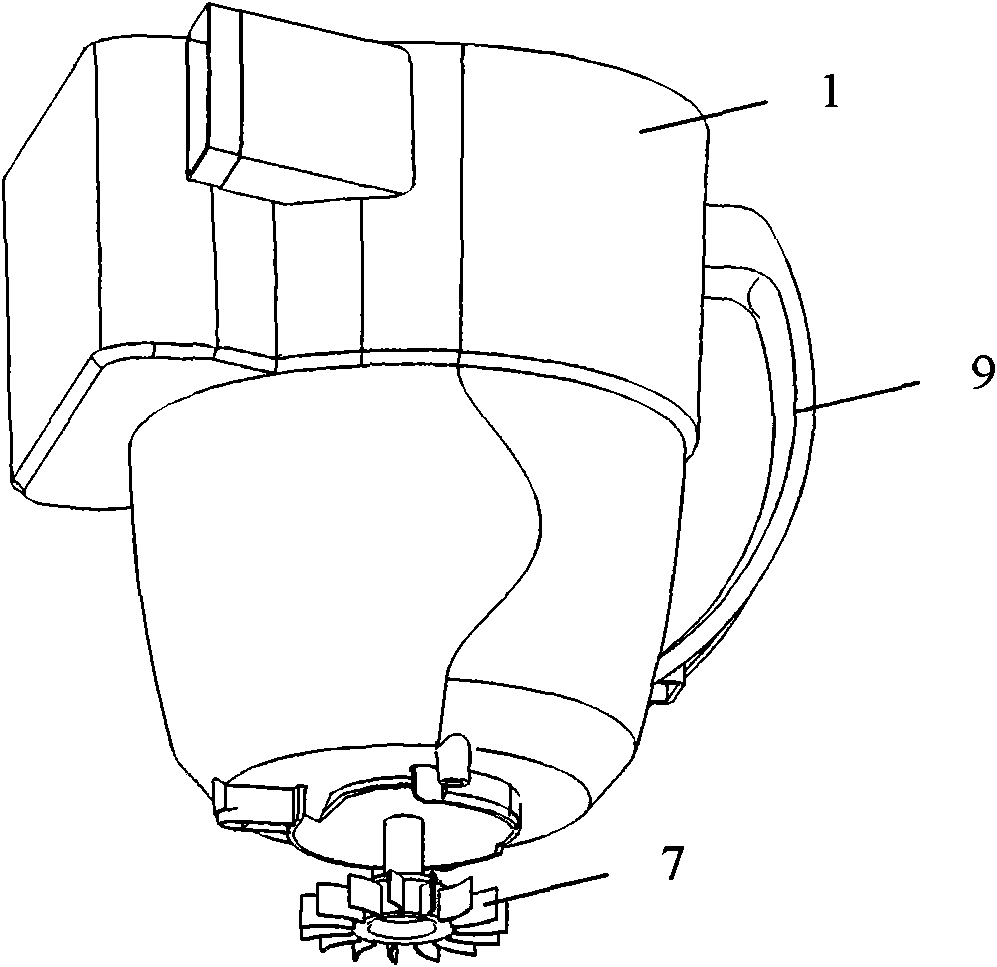

[0028] see image 3 , the present invention provides a new type of dust collecting bucket for vacuum cleaners including a dust collecting bin 1 for collecting the dust separated from the dust collecting bucket. The top of the dust bin 1 falls into the dust bin 1 , and a rotating shaft 2 is provided at the bottom center of the dust bin 1 .

[0029] In the present invention, longitudinally distributed compression sheets 3 are fixed on the upper outer side wall of the rotating shaft 2, and a pneumatic wheel 7 is arranged at the lower end of the rotating shaft 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com