Apparatus for producing a pyrolysis product

A technology for pyrolysis products and equipment, which is applied in the field of equipment for producing pyrolysis products, and can solve the problems of not being allowed to be used in an effective way, problematic in application, unfriendly to the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

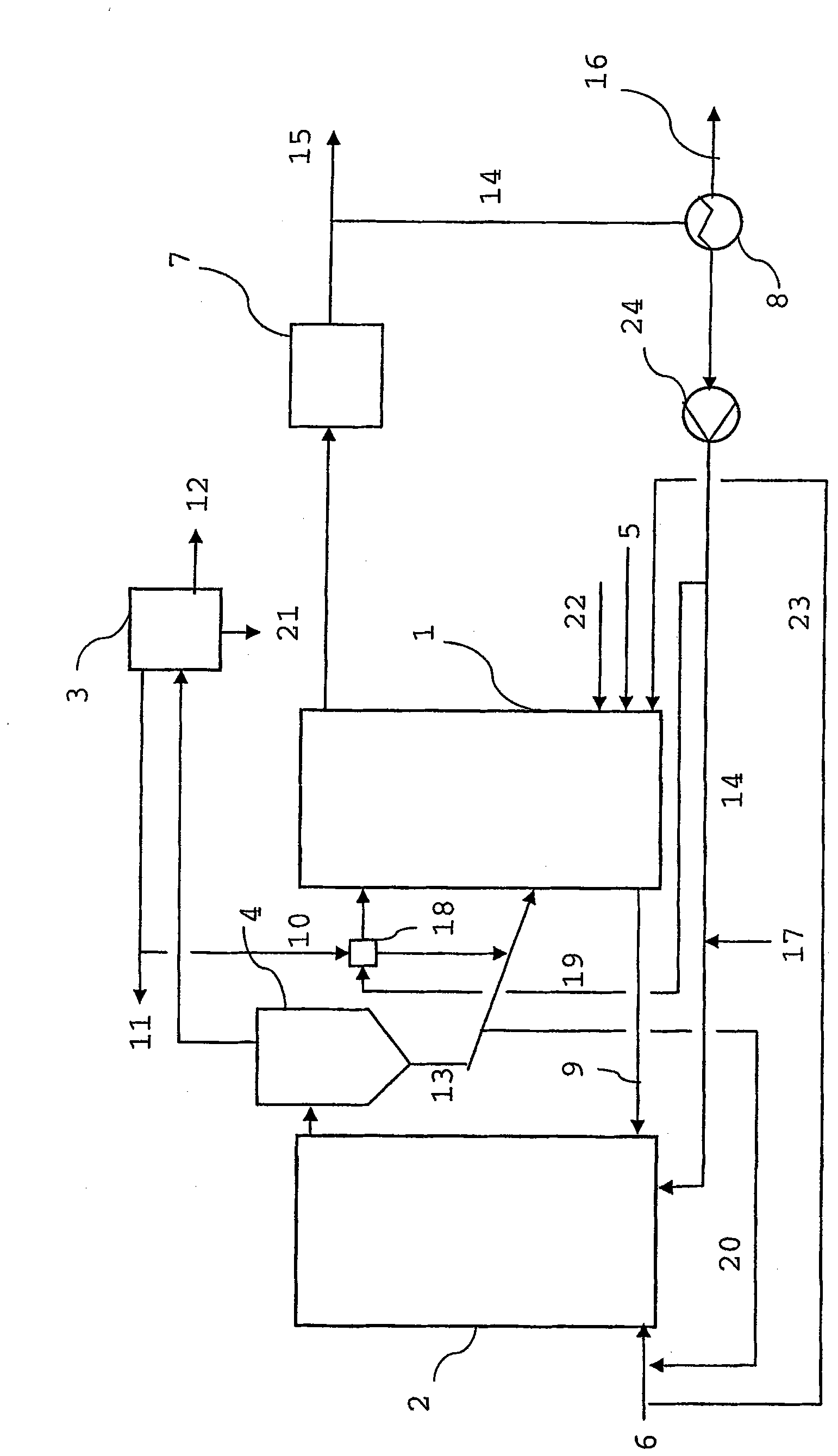

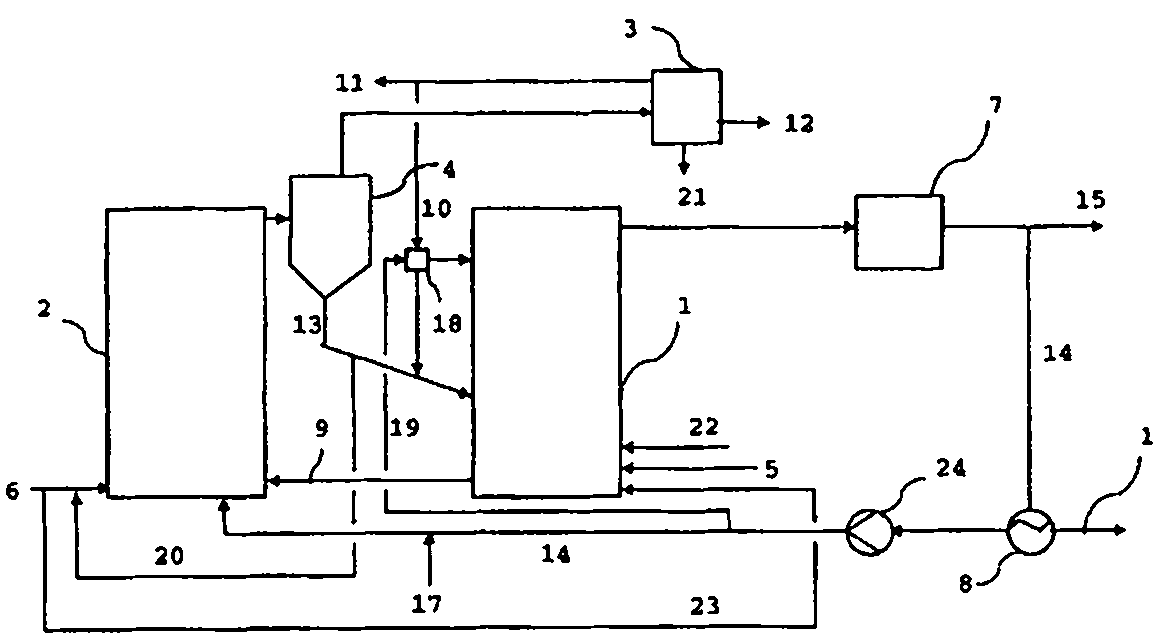

[0054] figure 1 Presented is an apparatus according to the invention for producing pyrolysis products comprising: a combustion boiler for generating heat energy, i.e. a fluidization boiler 1; a fast pyrolysis reactor for forming pyrolysis steam, i.e. a pyrolyzer 2; condensing unit 3 for condensing pyrolysis vapors; and separate fuel feed units 5 and 6 for supplying feedstock to the combustion boiler and pyrolyzer. Furthermore, the plant comprises a cyclone separator 4 for separating the solids and heat transfer medium from the pyrolysis vapor after the pyrolyzer 2 . The fluidization boiler, pyrolyzer, condensing unit and cyclone separator are combined in the manner presented in the figure. The pyrolyzer is integrated in connection with the fluidization boiler.

[0055] Most of the fuel, such as carbon, peat, lignite or oil shale, is supplied to the fluidized boiler 1 through the feed device 5 . Furthermore, the feeding device 5 is arranged to supply smaller quantities of tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com