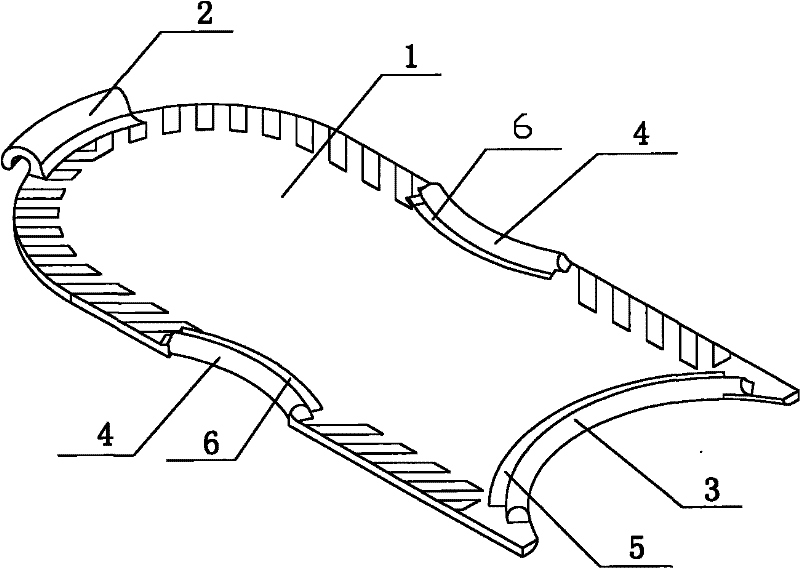

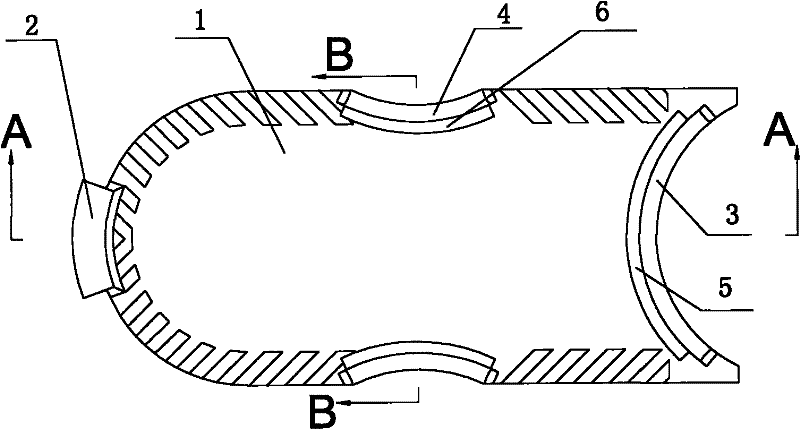

Novel cover plate for cable trench

A technology of cable cover and cover plate, applied in the direction of cable installation, ground cable installation, electrical components, etc., can solve the problems of easy dislocation, moving, inconvenient construction, heavy cable cover plate, etc., to increase the overall compression resistance. Strength, beautiful appearance and the effect of saving steel use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The preparation method of well cover of the present invention comprises the following steps:

[0067] 1) Add unsaturated polyester resin and low-shrinkage additives into the reactor, close the switch and start stirring at a stirring speed of 600-800 rpm;

[0068] 2), add heavy calcium carbonate to the reactor that has started to stir, then add zinc stearate, continue stirring for 50-80 minutes after adding;

[0069] 3) After stopping stirring, put the raw materials in the reaction kettle into the mixing bucket, add active magnesium oxide, curing agent, carbon black into the mixing bucket, then push the mixing bucket under the secondary mixer, and stir for 10-15 minutes , the stirring speed is 500-700 rpm, so that the raw materials are evenly mixed into a resin paste, and then the resin paste is divided into four upper paste barrels;

[0070] 4) Add non-alkali glass fiber roving to a sheet molding compound molding machine, adjust the gap between the scraper and the tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com