Film solar battery module with transparence and process method thereof

A technology of solar cells and process methods, applied in the field of thin-film solar cell modules, can solve problems such as large control difficulties, increased production costs, and unsuitability for high-quality mass production, and achieve the effects of simple processes and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

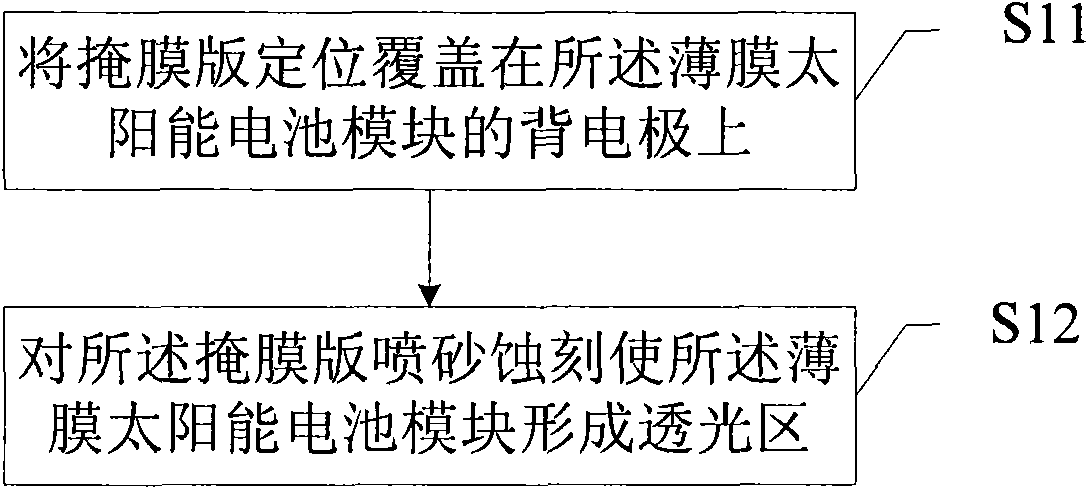

[0021] Such as figure 1 As shown, the manufacturing method of the thin film solar cell module with light transmission of the present invention includes:

[0022] S11, positioning the mask on the back electrode of the thin film solar cell module;

[0023] S12, sandblasting and etching the mask to form a light-transmitting region in the thin film solar cell module.

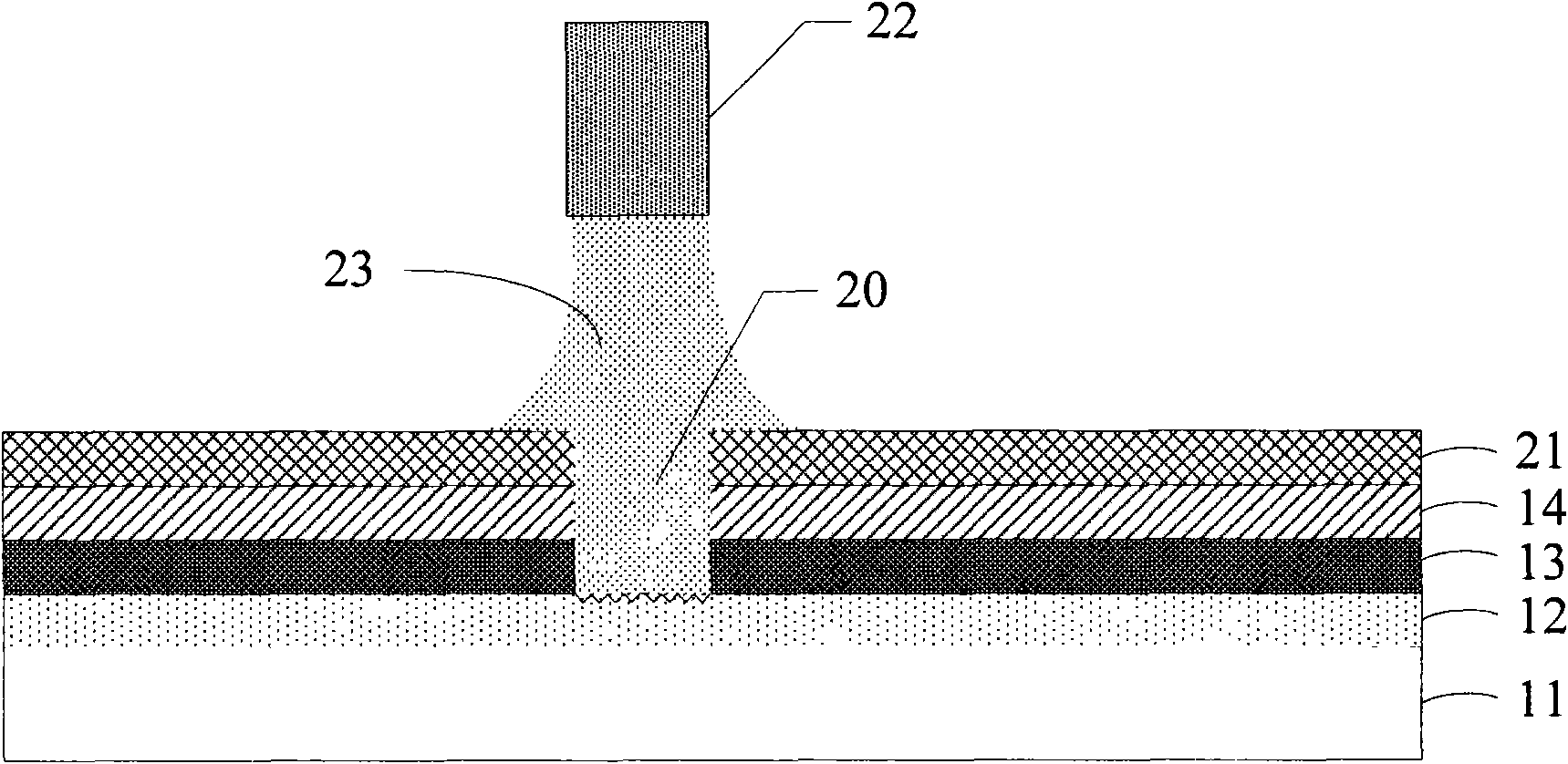

[0024] The process of forming the light-transmitting area by the mask-assisted sandblasting etching process is as follows: figure 2 As shown in the schematic diagram, the thin-film solar cell module includes an insulating and transparent substrate 11 , a transparent electrode layer 12 , a semiconductor layer 13 , and a back electrode layer 14 . Position and cover the pre-processed patterned mask plate 21 on the back electrode layer 14, sandblast the mask plate 21 by the sandblasting equipment 22, control the depth of sandblasting and etching by the control unit, and place the back electrode layer 14 After the se...

Embodiment 2

[0030] On the basis of embodiment one, in order to further improve product quality, as Figure 5 The flow chart of the process method for manufacturing the light-transmitting thin-film solar cell module shown in this embodiment, after forming the light-transmitting region, also includes:

[0031] S21, providing an isolation line along the outer side of the light-transmitting area.

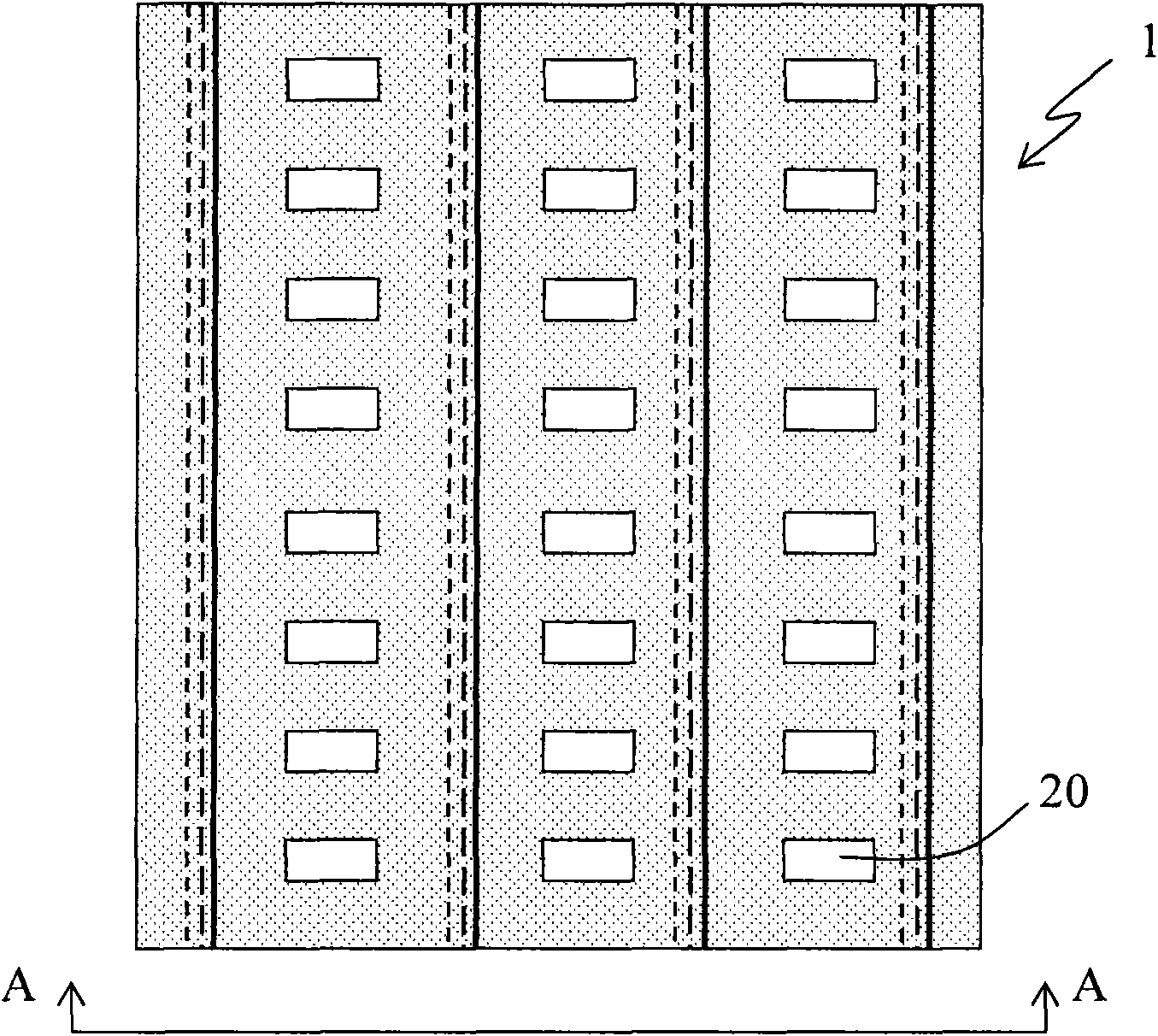

[0032] Such as Image 6 The front schematic view of the light-transmitting thin-film solar cell module is shown, and the light-transmitting regions 50 in the figure are equal-spaced parallel straight-line open grooves. In the process of forming the light-transmitting region 50 using the sand-blasting etching process for the opening groove of this shape, the sandblasting 23 may accumulate at the edge of the light-transmitting region 50, because the sandblasting 23 usually contains metal particles, and in addition, the sandblasting During the process, the etched metal electrodes will produce a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com