Three-dimensional cross-shaped biaxial tension test piece

A two-way stretching, three-dimensional cross technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to achieve large deformation, uneven force in the central area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

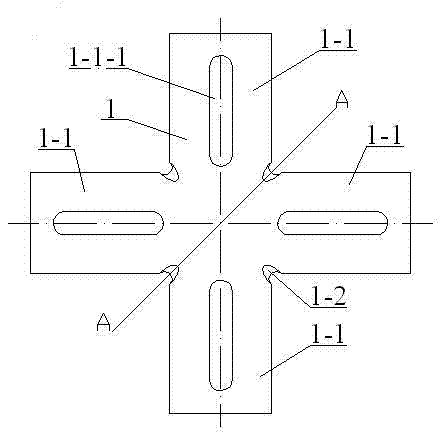

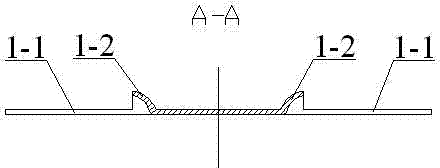

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 2 Describe this embodiment, this embodiment is made up of a cross-shaped drawing member 1, and the end surface of the junction of every two adjacent arms among the four arms 1-1 on the cross-shaped drawing member 1 is provided with a pit 1- 2. The four dimples 1-2 are located on the same side of the cross-shaped tensile member 1 . When the pits 1-2 at the rounded corners between the arms are subjected to external force, the geometric deformation is much greater than the plastic deformation; as the bidirectional tensile stress of the specimen increases, the deformation of the central area also begins to increase, and the pits Part 1-2 undergoes greater geometric deformation, and may even be completely flattened in the end, resulting in significant shape deformation. This geometric deformation process alleviates most of the original stress concentration effect, so that the tensile stress on the cross-shaped arm...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, the cross-sectional shape of each dimple 1-2 in this embodiment along the bisector of the angle between its two adjacent arms is a quarter ellipse or a quarter arc. The shape of the pit 1-2 is selected according to the ratio of the two-way load on the cross-shaped tensile member 1 . Other compositions are the same as in Embodiment 1.

specific Embodiment approach 3

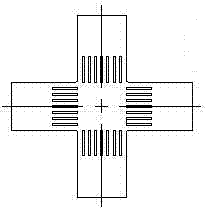

[0009] Specific implementation mode three: combination figure 1 To describe this embodiment, the wall thickness of each arm 1-1 of the cross-shaped tensile member 1 of this embodiment is provided with a long hole 1-1-1. The long hole 1-1-1 can relieve the stress concentration in the central area, making the stress distribution in the central area more uniform. Other compositions are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com