Electric-hydraulic controlled power output clutch with hydraulic brake

A technology of power output and hydraulic braking, applied in the field of tractors, can solve problems such as inability to arrange and difficult, and achieve the effect of improving service life and reliability, small size, and improving positive pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

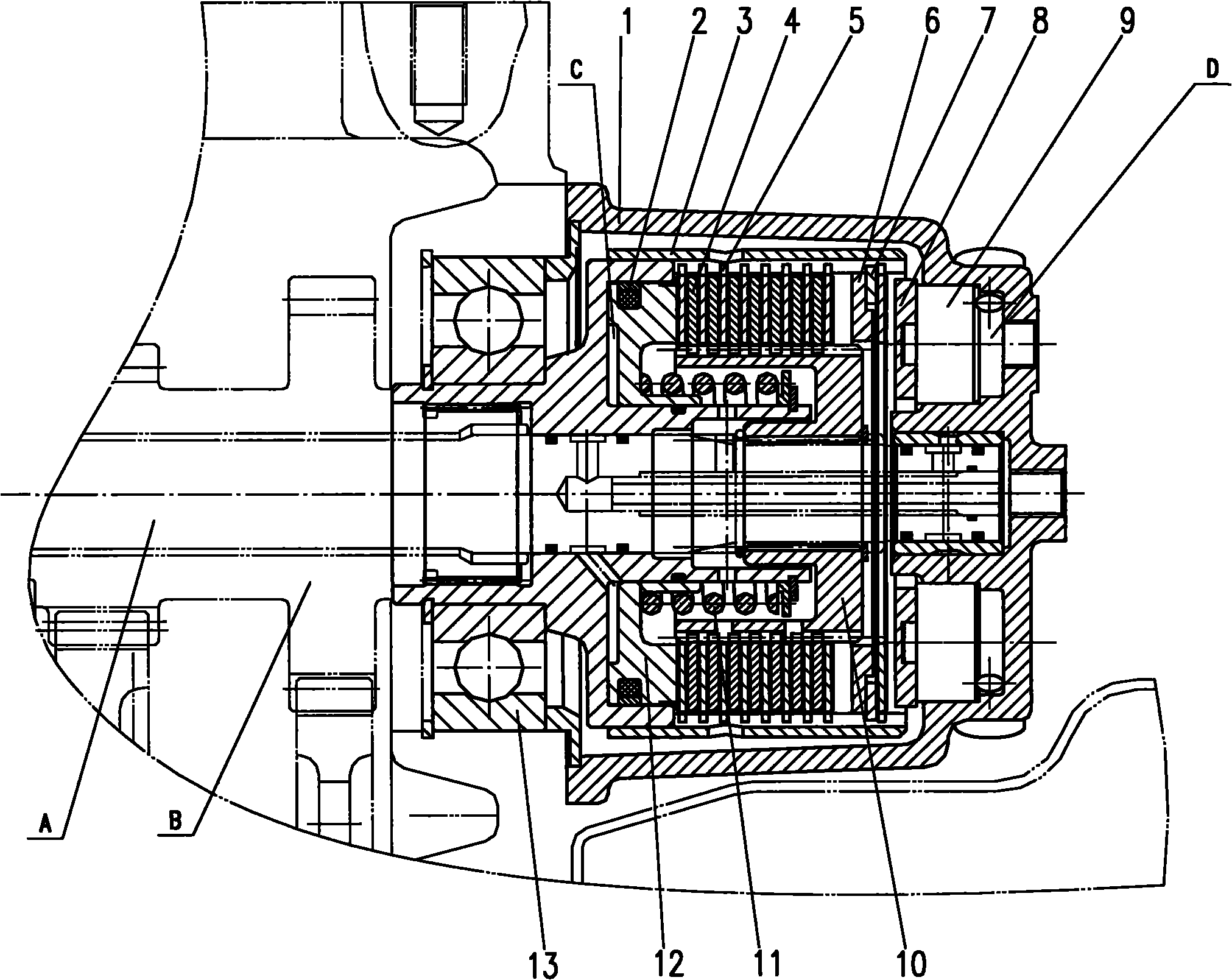

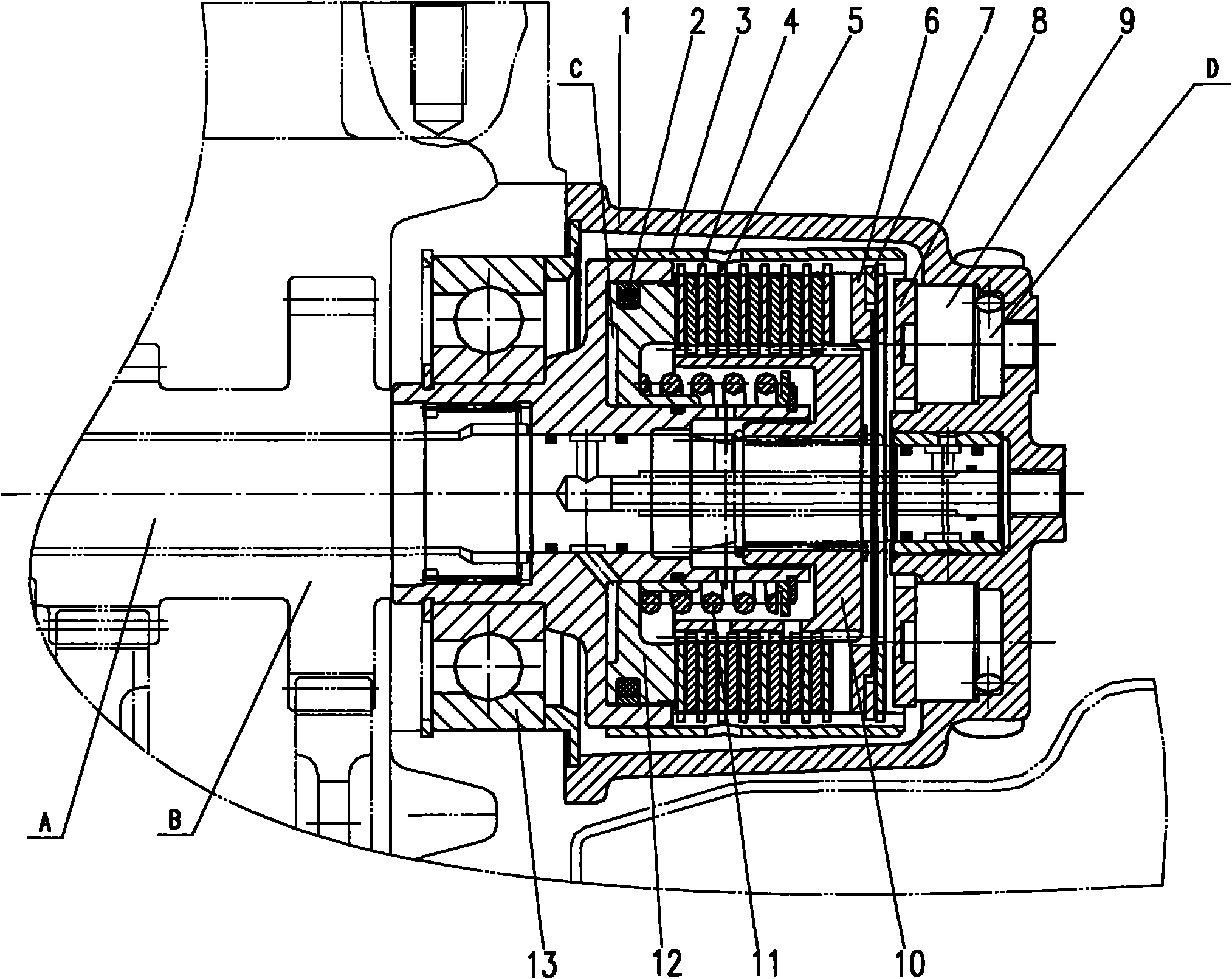

[0009] As shown in the accompanying drawings, the power output clutch device with electro-hydraulic control and hydraulic brake is mainly composed of a power output clutch housing 1, a coaxial sealing ring 2, a driven hub 3, an active friction plate 4, a driven friction plate 5, Block plate 6, circlip 7, brake friction plate 8, brake piston 9, driving hub 10, helical return spring 11, clutch piston 12, bearing 13 and so on. The driving hub 10 is keyed to the power output clutch shaft A of the tractor, and the driven hub 3 is keyed to the first shaft B of the tractor power output transmission box. Between the driving hub 10 and the driven hub 3, there are 5 to 9 pairs of driving friction plates 4 and driven friction plates 5 installed crosswise. A spiral return spring 11 is installed between the clutch piston 12 and the driven hub 3; two brake pistons 9 are installed at the rear of the power output clutch housing 1; a circlip 7 is installed at the rear of the driven hub 3, The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com