Vacuum gas diaphragm circulating pump for tritium purification

A technology of circulating pump and diaphragm, applied in the field of vacuum gas diaphragm circulating pump, can solve the problems of large power and volume, and achieve the effects of enhancing safety, improving recovery efficiency and reducing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

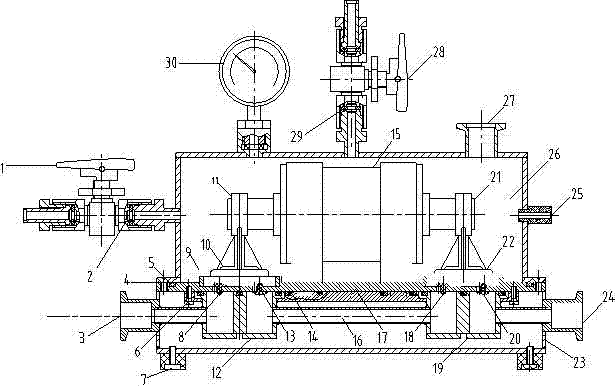

[0020] figure 1 It is a structural schematic diagram of an embodiment of a vacuum gas diaphragm circulation pump for tritium purification according to the present invention. from figure 1 It can be seen from the figure that the pump body of the vacuum gas diaphragm circulation pump for tritium purification of the present invention is set as a double-layer structure. The circulation pump of the present invention includes a bracket 23 , a primary container 16 , a base 17 , a motor 15 and a secondary container 26 . The primary container 16 is a left-right symmetrical structure, fixedly arranged on the support 23, the top of the primary container 16 is provided with a base 17, the base 17 is fixedly connected with the primary container 16 by four screw rods 1, and the screw rod 16 is one of them. The top of the base 17 is provided with a secondary container 26, and the secondary container 26 is connected with the base 17 by pressing the O-shaped fluororubber ring 5 arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com