Combined multi-stage pressure control method and device

A pressure control, combined technology, used in natural gas drilling pressure control equipment, oil field, can solve the problems of high cost, low control accuracy, wear resistance, poor impact resistance, etc., to reduce damage and failure problems, expand control scope, the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

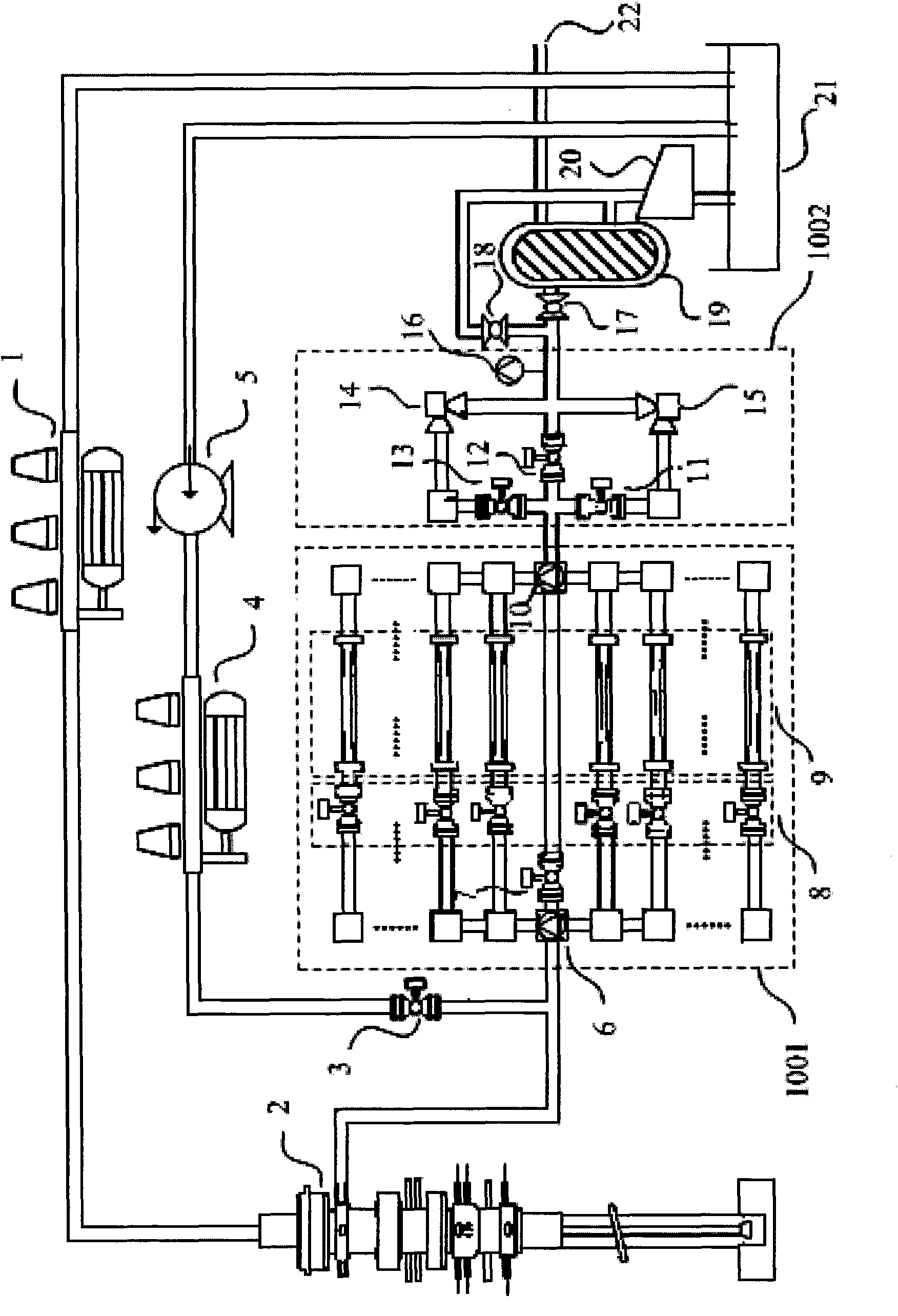

[0024] Embodiment 1: Taking a combined multi-stage pressure control device and control method as an example, the present invention will be further described in detail.

[0025] refer to figure 1. The combined multi-stage pressure control device is mainly composed of mud pump 1, rotary control head 2, first self-control plate valve 3, back pressure pump 4, filling pump 5, first ball valve 17, second ball valve 18, airtight separator 19, Vibrating screen 20, mud tank 21, coarse flow control system 1001 and fine flow control system 1002 are composed. The dynamic sealing pressure of the rotary control head 2 is 14MPa, the static sealing pressure is 35MPa; the back pressure pump 4 can choose 160 pump, the rated working pressure: 35MPa, the displacement: 8L / s; the liquid handling capacity of the airtight separator 19: 200m 3 / h, gas handling capacity: 20000m 3 / h, working pressure: 1.5MPa.

[0026] The inlet of the mud pump 1 is connected to the mud tank 21 by a pipeline, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com