Method for preparing self-cleaning protective film of solar cell

A solar cell and self-cleaning technology, which is applied in the field of preparation of solar cell self-cleaning protective film, can solve problems such as solar cells are easily broken and easily corroded, achieve low cost, increase transmittance, and reduce transmittance decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

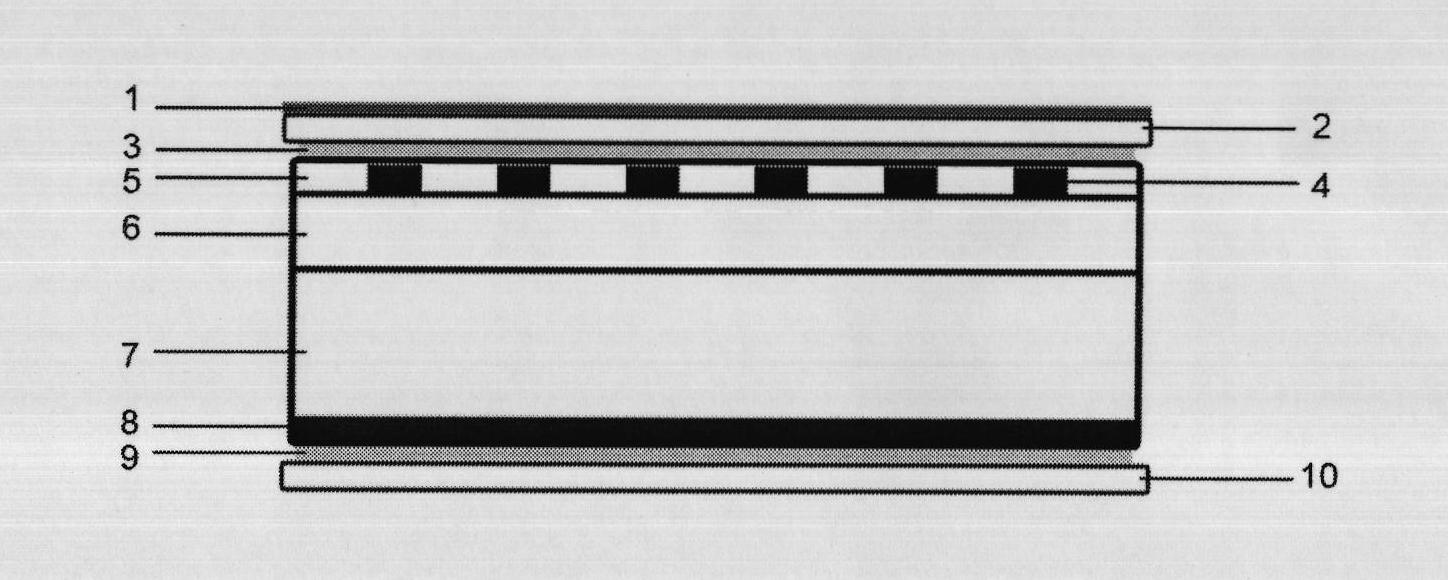

Image

Examples

Embodiment 1

[0029] Using 12ml of ethyl orthosilicate, 40ml of ethanol and 6ml of water as raw materials, hydrochloric acid as a catalyst (3~5 drops to make the solution PH=3), carry out hydrolysis and polycondensation reaction at 70~75℃, add 0.25% in the process (mol %) EuCl 3 ·6H 2 Doping with O, adjust the pH to 3 after the solution is cooled, fully stir for 1 hour, and stand for 2-12 hours to prepare for coating.

[0030] Rinse the substrate glass with detergent and deionized water several times, then put it in absolute ethanol and clean it with an ultrasonic cleaner for 15 minutes, and finally wipe the surface droplets with lens paper, and place it in an electric blower at 50℃ Dry for later use.

[0031] Use a homogenizer to coat the substrate at room temperature, and set the first-stage rotation speed to 500 rpm and the time to 9s; the second stage rotation speed to 3950 rpm and the time to 30s. The coated glass is first dried in a drying oven at 50°C for half an hour, and then the sampl...

Embodiment 2

[0038] Using 12ml of ethyl orthosilicate, 40ml of ethanol and 6ml of water as raw materials, hydrochloric acid as a catalyst (3~5 drops to make the solution PH=3), carry out the hydrolysis and polycondensation reaction at 70~75℃, and add 0.5% in the process (mol %) EuCl 3 ·6H 2 Doping with O, adjust the pH to 3 after the solution is cooled, fully stir for 1 hour, and stand for 2-12 hours to prepare for coating.

[0039] Rinse the substrate glass with detergent and deionized water several times, then put it in absolute ethanol and clean it with an ultrasonic cleaner for 15 minutes, and finally wipe the surface droplets with lens paper, and place it in an electric blower at 50℃ Dry for later use.

[0040] Use a homogenizer to coat the substrate at room temperature, and set the first-stage rotation speed to 500 rpm and the time to 9s; the second stage rotation speed to 3950 rpm and the time to 30s. The coated glass is first dried in a drying oven at 50°C for half an hour, and then th...

Embodiment 3

[0047] Using 12ml of ethyl orthosilicate, 40ml of ethanol and 6ml of water as raw materials, hydrochloric acid as a catalyst (3~5 drops to make the solution PH=3), carry out the hydrolysis and polycondensation reaction at 70~75℃, and add 0.75% during this process (mol %) EuCl 3 ·6H 2 Doping with O, adjust the pH to 3 after the solution is cooled, fully stir for 1 hour, and stand for 2-12 hours to prepare for coating.

[0048] Rinse the substrate glass with detergent and deionized water several times, then put it in absolute ethanol and clean it with an ultrasonic cleaner for 15 minutes, and finally wipe the surface droplets with lens paper, and place it in an electric blower at 50℃ Dry for later use.

[0049] Use a homogenizer to coat the substrate at room temperature, and set the first-stage rotation speed to 500 rpm and the time to 9s; the second stage rotation speed to 3950 rpm and the time to 30s. The coated glass is first dried in a drying oven at 50°C for half an hour, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com