Flame cutting head

A flame cutting and cutting torch technology, applied in gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reduced cutting quality, hanging slag, unevenness of the plate, and achieve the effect of improving quality and cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

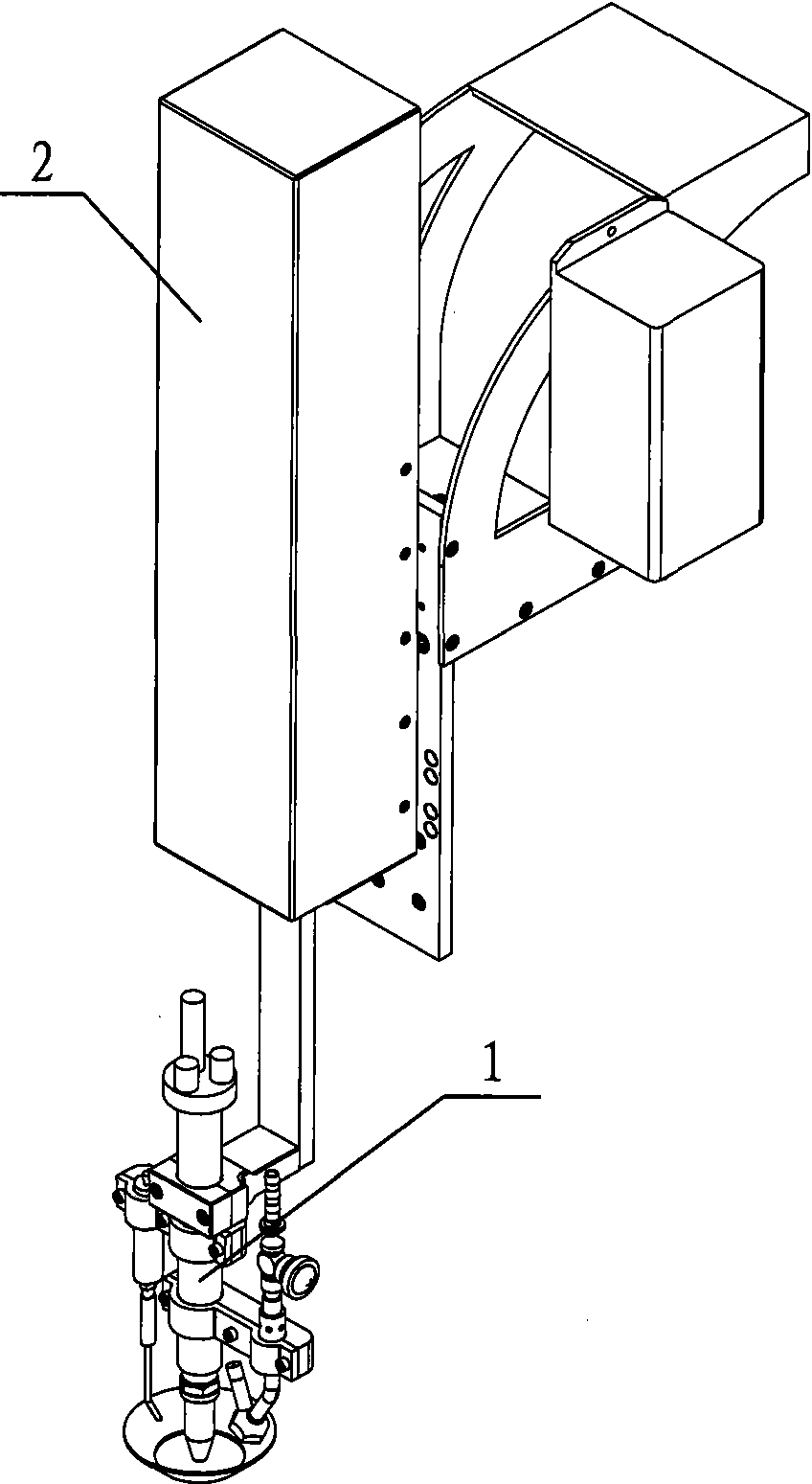

[0021] See attached figure 1 shown.

[0022] A flame cutting head includes a cutting torch 1 and a self-locking and automatic height-adjusting lifting device 2 .

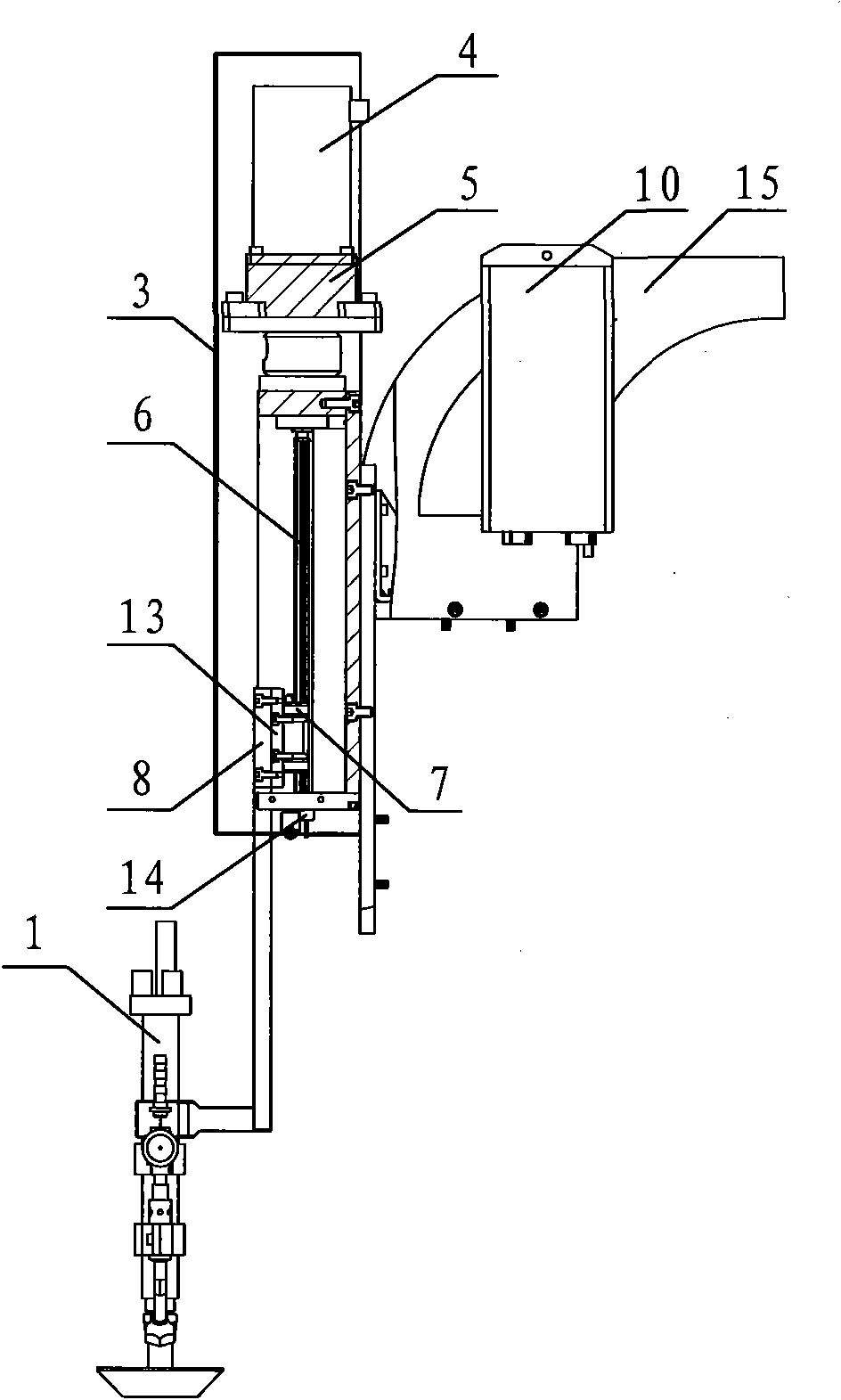

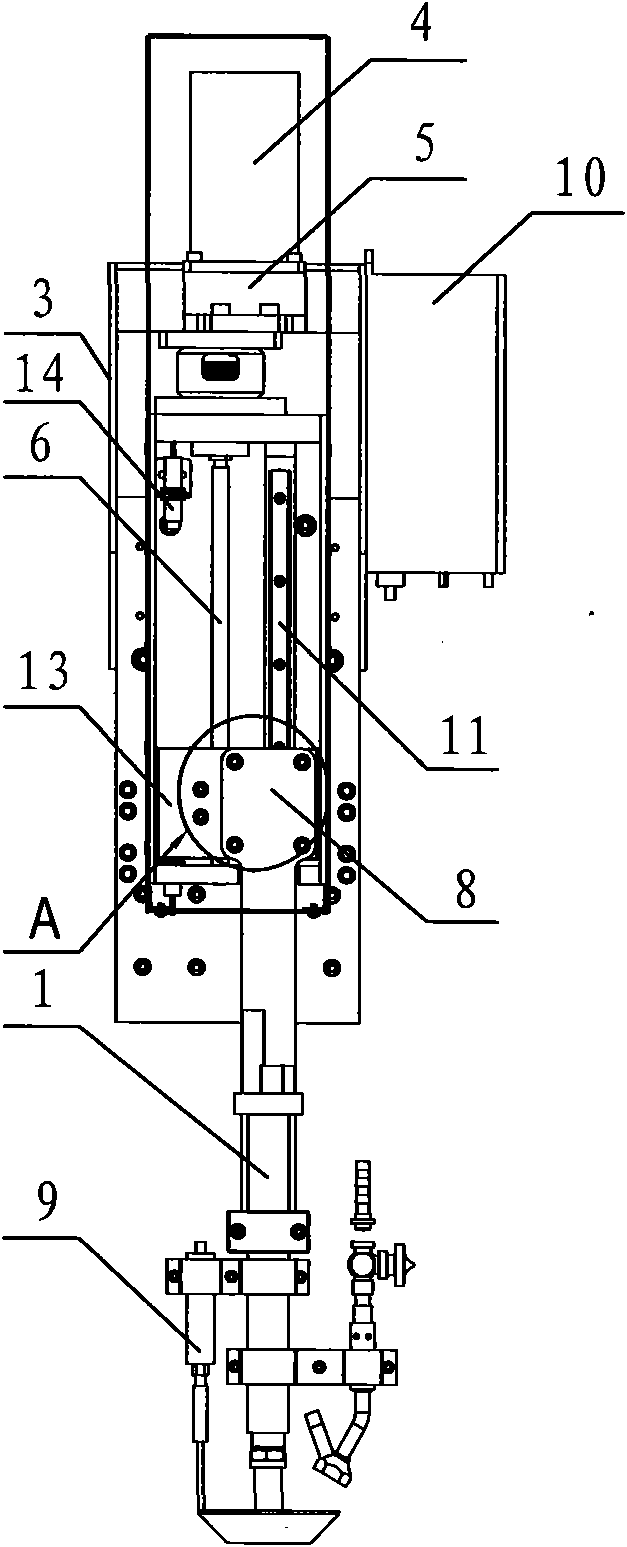

[0023] See attached figure 2 to attach Figure 4 shown.

[0024] The self-locking automatic height-adjusting lifting device 2 includes a casing 3, a motor 4 arranged in the casing 3, a speed reducer 5 connected to the output shaft of the motor 4, a T-shaped lead screw 6 connected to the speed reducer 5, The nut 7 matched with the T-shaped lead screw 6, the lifting plate 8, the arc voltage height adjustment sensor 9 arranged on the cutting torch 1, the height adjustment device 10 connected with the arc voltage height adjustment sensor 9; the casing 3 A linear guide rail 11 parallel to the T-shaped lead screw 6 is also provided inside, a slider 12 that can slide along its axial direction is arranged on the linear guide rail 11, a slide plate 13 is connected between the slider 12 and the nut 7, and a lifting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com