Printed wiring board and manufacturing method of the same

A technology for printed circuit boards and substrates, applied in the directions of printed circuit manufacturing, printed circuits, printed circuit dielectrics, etc., can solve the problems of difficulty in simplifying the manufacturing process, complexity, and low adhesion of insulating substrates, and achieve the effect of realizing the manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

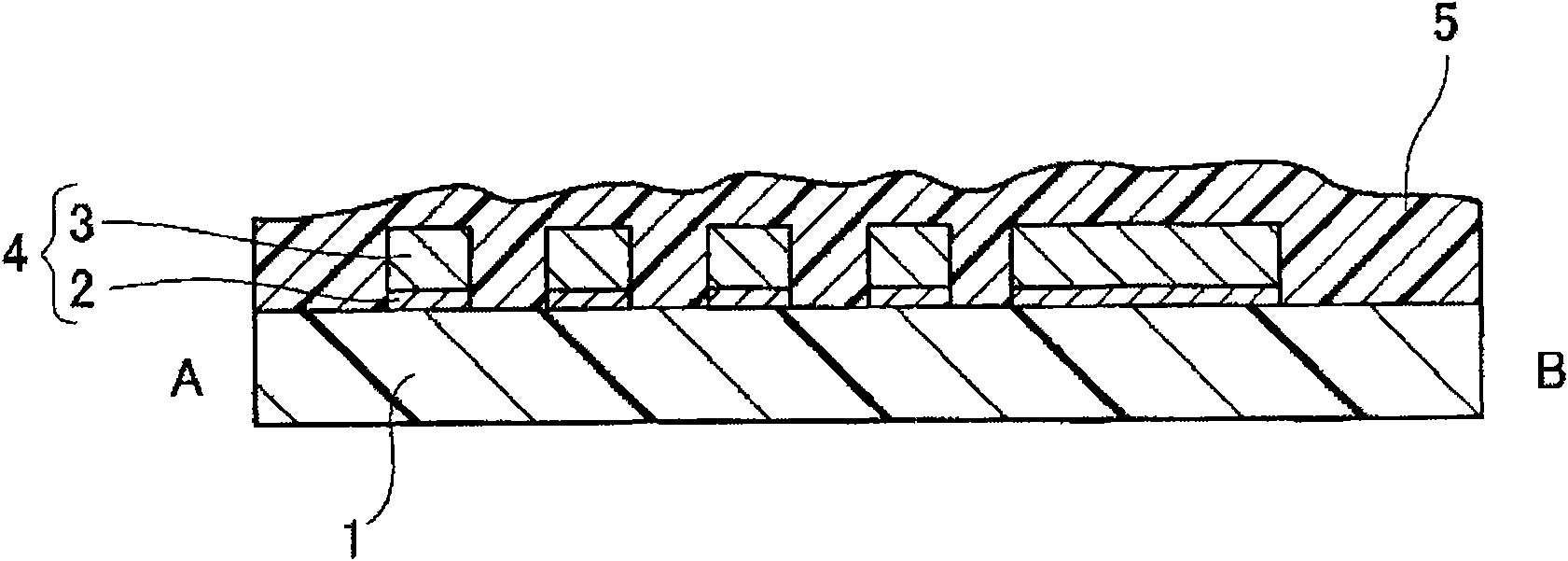

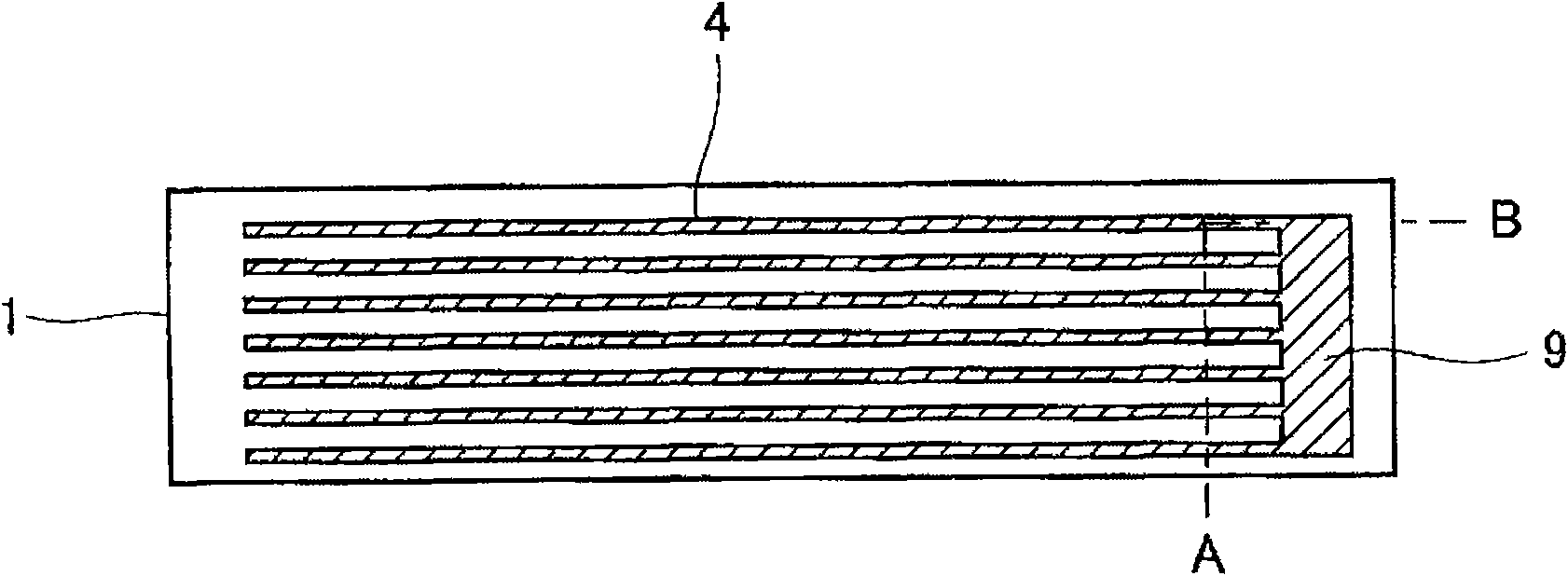

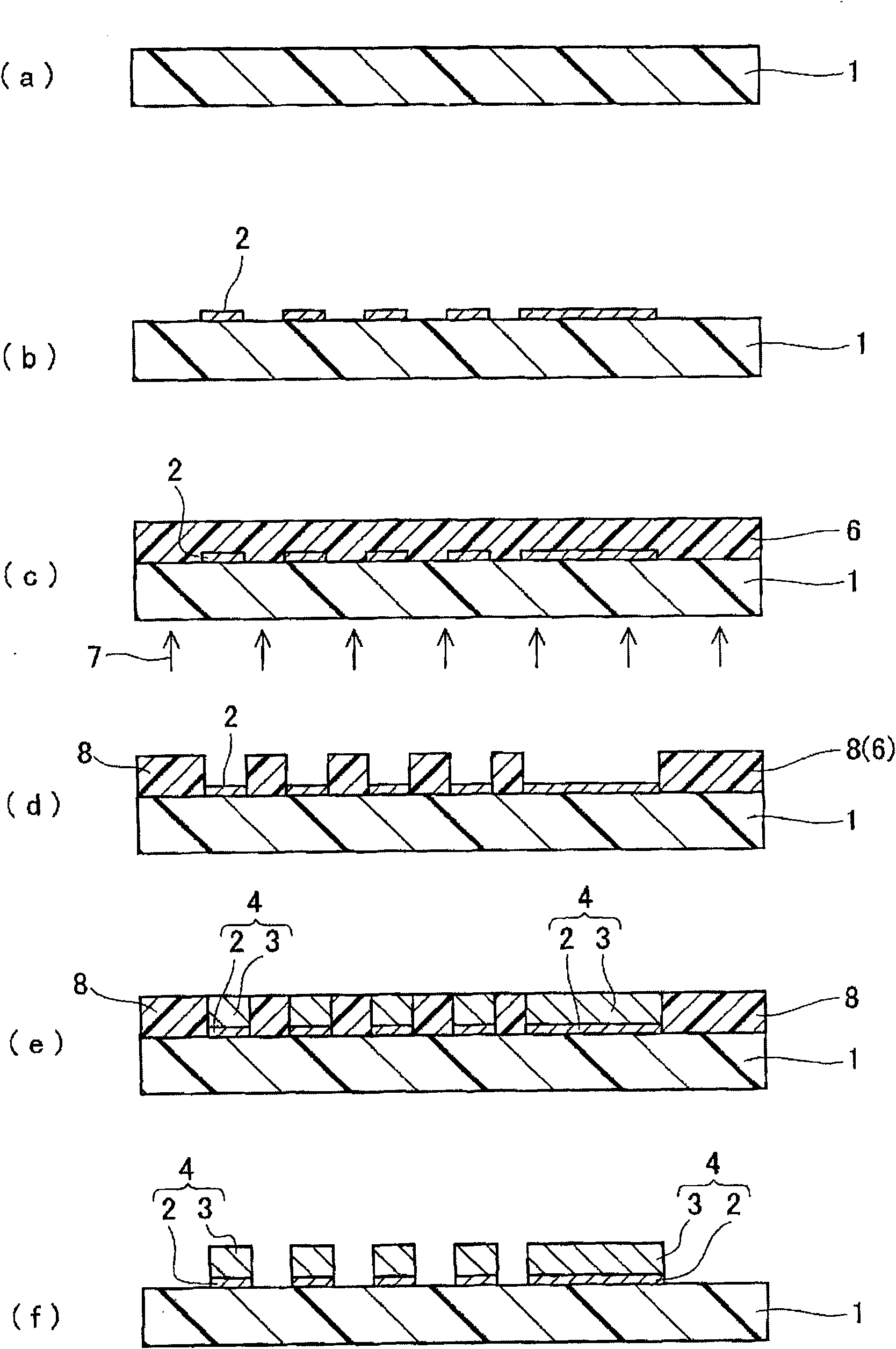

[0065] The printed wiring board of the example of the present invention was produced according to the production method described in the above embodiment.

[0066]The insulating substrate 1 needs to be of a material suitable for exposing the photoresist 6 from the back surface thereof. Commonly used photoresists are often programmed to use UV light exposure. Therefore, considering this as a premise, in this embodiment, as the insulating substrate 1, an insulating film base material for a carrier tape type printed circuit board suitable for a signal transmission path in the millimeter wave band is used. , A sheet of a liquid crystal polymer with a small Tanδ. In addition, the insulating substrate 1 is not limited to liquid crystal polymers, and for example, PET (polyethylene terephthalate, Poly Ethylene Terephthalate), PEN (polyethylene naphthalate, Poly Ethylene Terephthalate) can also be used. Naphthalate), PE (polyethylene, Poly Ethylene), etc., which have good durability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com