Method for forming annular deformation parameterized rubber grid suitable for large deformation

A forming method and parametric technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., to achieve the effect of accurate stress results and high mesh quality

Inactive Publication Date: 2010-11-17

ZHUZHOU TIMES NEW MATERIALS TECH

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the shortcomings of the existing rubber material unit grid forming method, and propose a ring-like pentagonal deformation and parameterization that can better meet the large deformation requirements of rubber materials and reduce grid distortion and hourglass formation. Forming method of rubber unit mesh

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

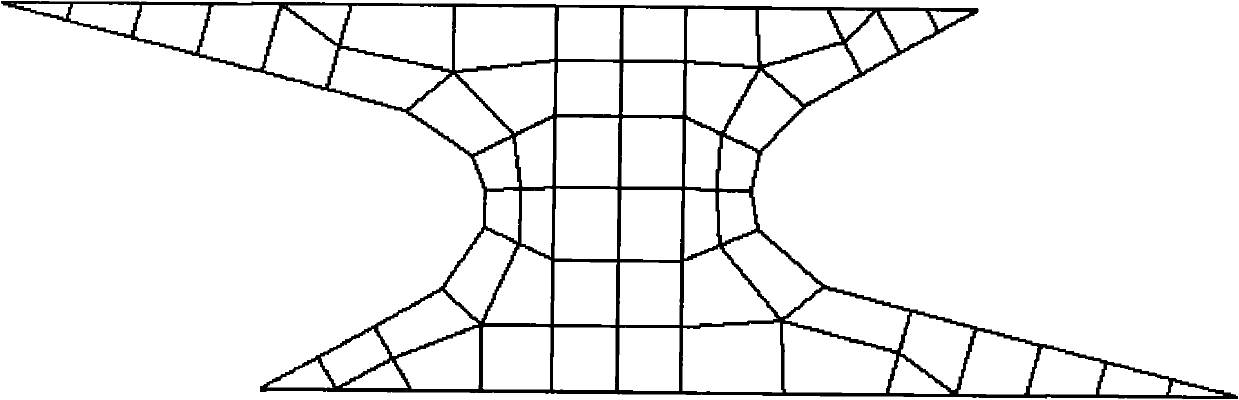

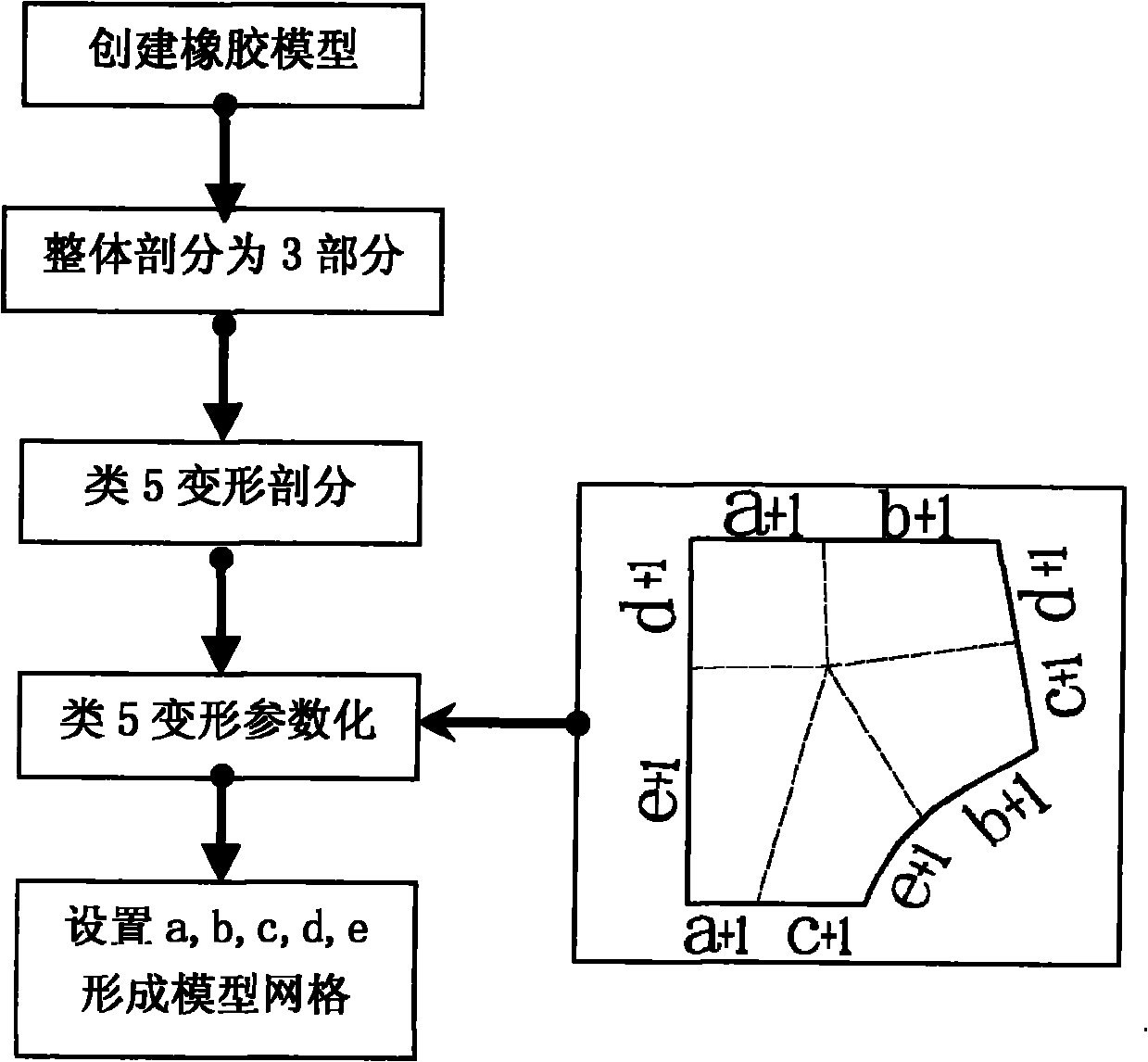

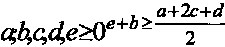

The invention discloses a method for forming an annular deformation parameterized rubber grid suitable for large deformation. The method comprises the following steps of: sectioning an entire model into a left region, a middle region and a right region; sectioning the left region and the right region which produce large deformation easily and have serious grid distortion into four pentagon-like regions in all; performing parameterized grid setting at each local pentagon-like region; and making the number of grids on each side meet the following requirements: a, b, c, d and e are greater than 0 and e+b is more than or equal to a+2c+d / 2, wherein the grid layout and the grid state after the forming of the grid, which meet the requirements of the formula, form the annular pentagon-like deformation rubber grid with different grid densities and the same grid layout through parameterized adjustment of the number of the grids according to the requirements on the size of the model and the analysis quality.

Description

technical field The invention relates to a molding method of rubber, in particular to a ring-type, parameterized full quadrilateral rubber grid molding method that can adapt to large deformation. Using this mesh forming method, the rubber model with complex structure can be sculpturally subdivided, and then the local area can be generated based on ring-type 5-type deformation and parametric mesh to meet the requirements of large deformation, so that large deformation can be achieved. The solution analysis was successfully completed. Background technique The rubber material has a small modulus of elasticity, a large amount of deformation under load, and a high degree of nonlinearity. Nowadays, rubber molding is used to simulate and fit the deformation behavior of rubber materials (or rubber elastic components) using finite element technology, but from the perspective of use, when using finite element technology to simulate the deformation behavior of rubber materials (or rub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

Inventor 黄友剑张亚新王宏刘建勋

Owner ZHUZHOU TIMES NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com