Supporting system for machining of large-caliber space optical reflectors

A space optics and support system technology, applied in optics, optical components, installation, etc., can solve the problems of the inability to realize space-based space optical systems, the different mechanical environments of space and ground, and the inability to correct large local deformations, so as to improve the conversion efficiency. and conversion safety, reduce detection errors, and ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

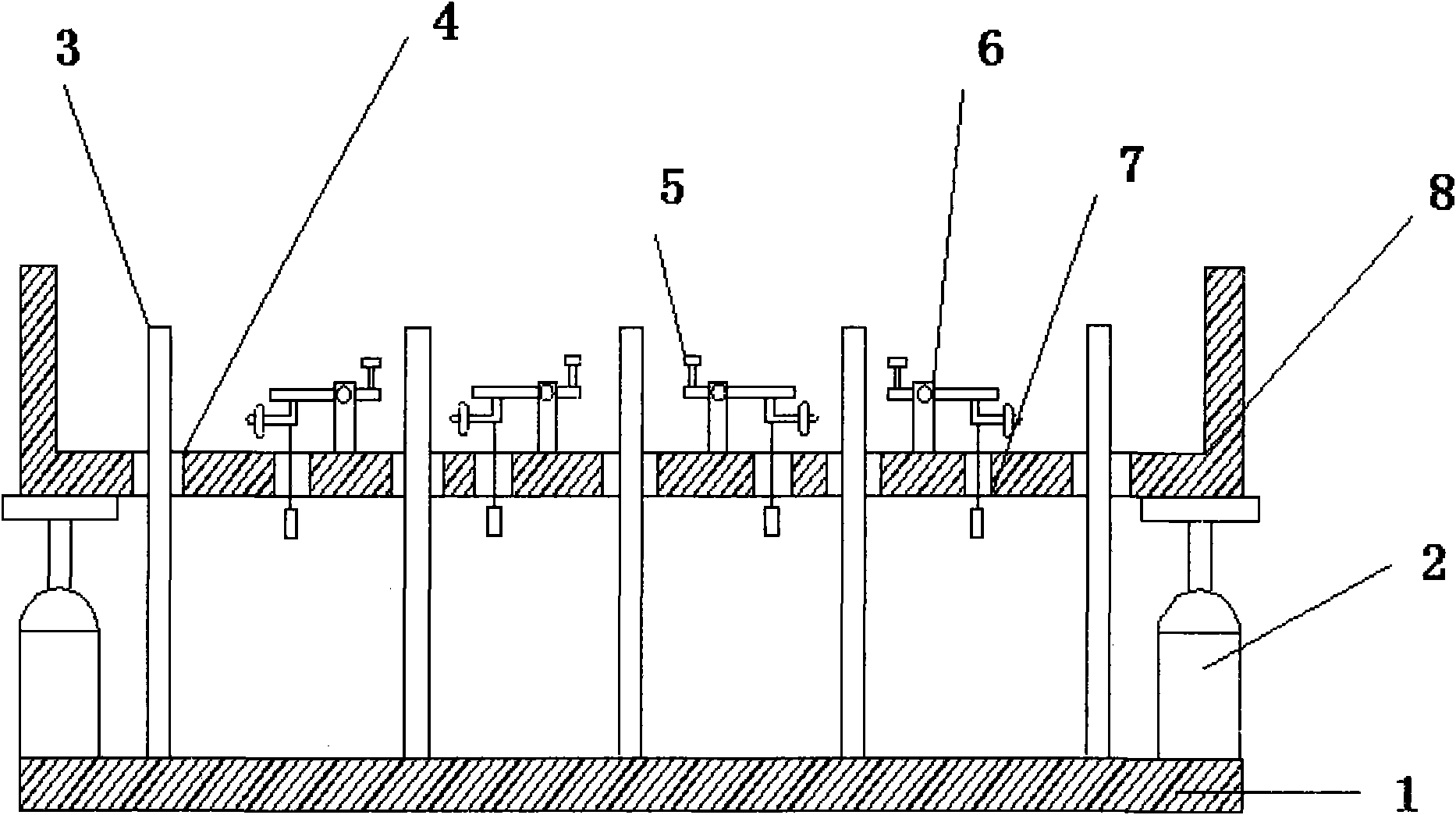

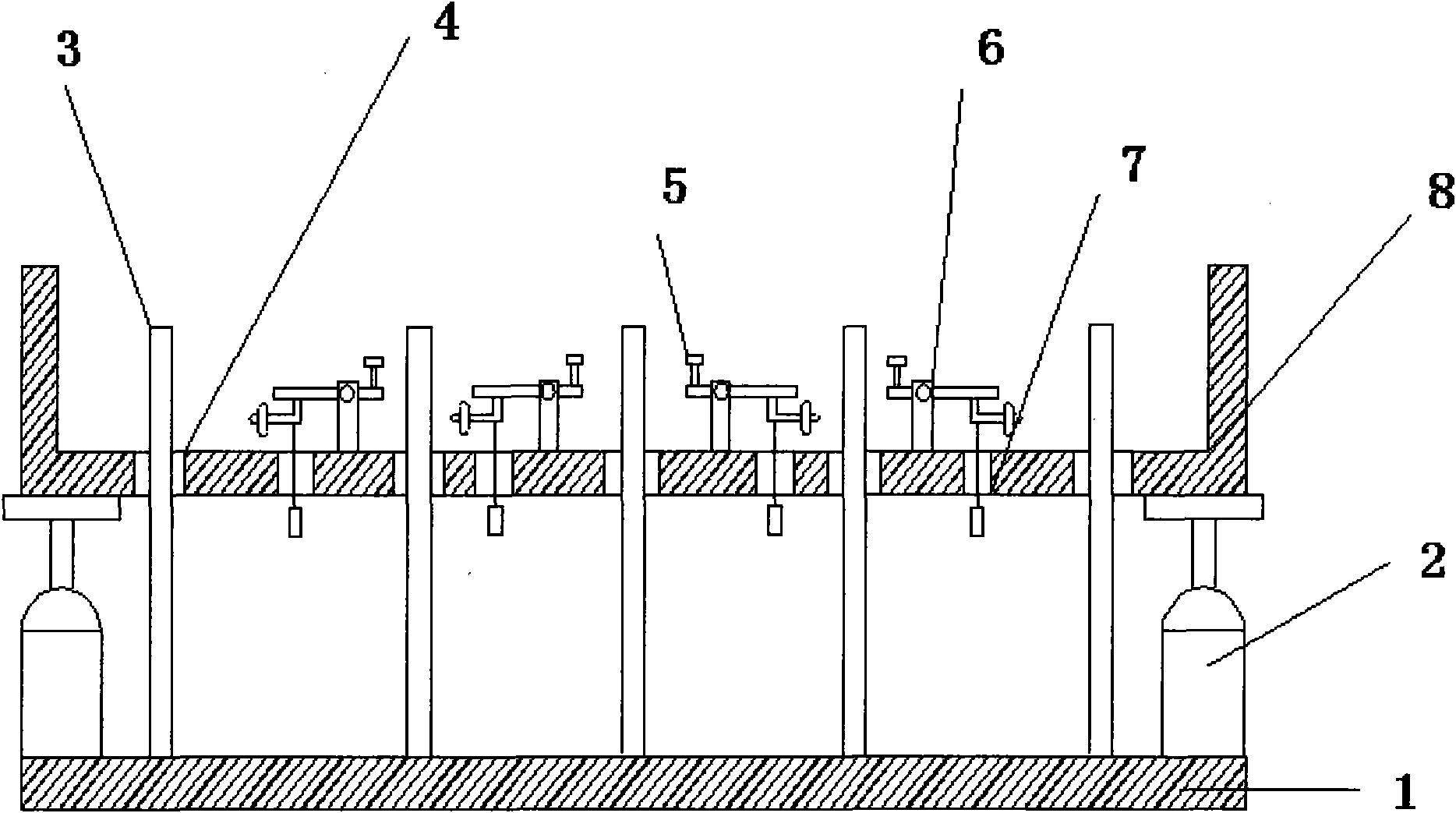

[0026] See attached figure 1 , which is a schematic structural cross-sectional view of a support system for processing large-aperture space optical mirrors provided in this embodiment. Depend on figure 1 It can be seen that two sets of support systems are used for the detection and processing of mirror workpieces. The rigid support rod 3 is installed on the processing support base plate 1 to form a processing support device. The device adopts rigid passive support to provide support force and bear the processing pressure; The detection support frame 8 and the floating active support mechanism 6 form a detection support device. The floating active support mechanism 6 is installed on the bottom plate of the detection support frame 8, and the three support points are fixed support points, which are evenly distributed on the same circumference. The support force is equal; there are rigid support rods passing through the hole 4 and the weight passing through the hole 7 on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com