Dual-substrate triangular arc support-blade asymmetrically-combined rotary flexible shaft supporting tube

An asymmetric and support tube technology, applied in the direction of flexible shafts, shafts, shafts and bearings, can solve the problems of unsatisfactory improvement effects, achieve the effects of preventing rotation, simple replacement, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

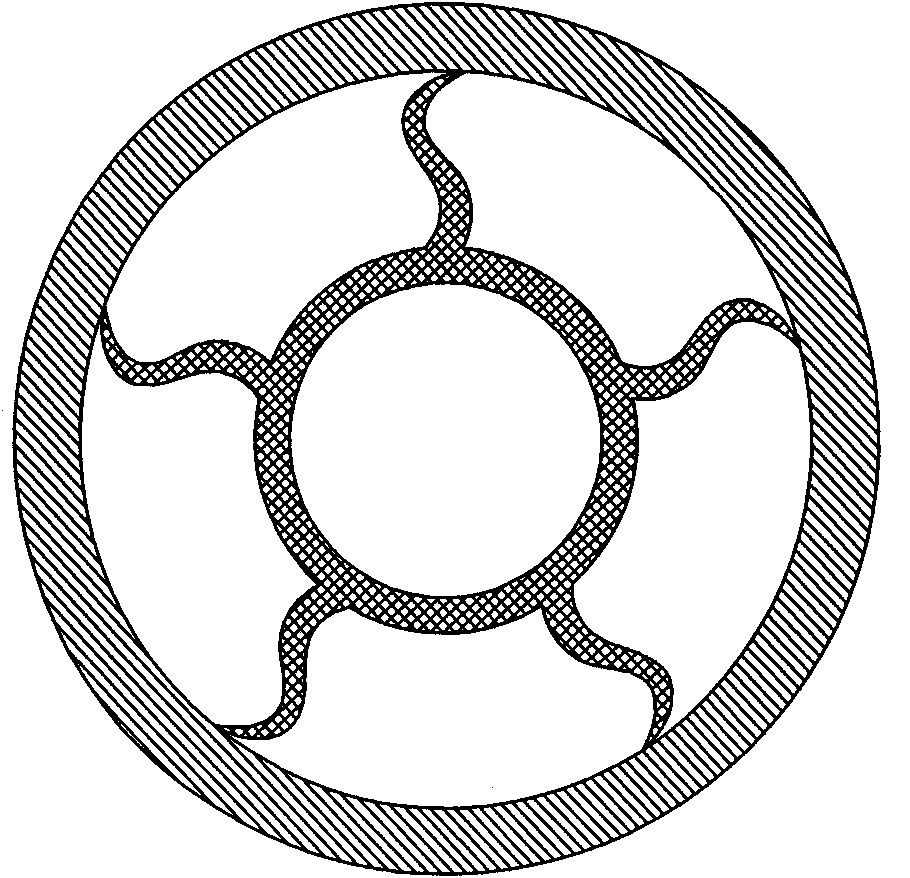

[0024] Embodiment 1: In the cross-section of the inner tube body 1, the line connecting the tip apex of the elastic support blade 3 and the center of the ring where the inner tube body 1 is located passes through the corresponding left lobe 3.1 of the elastic support blade 3 and the blade The outer wall surface of the inner tubular body 1 between the right lobe 3.2, such as Figure 4 .

Embodiment 2

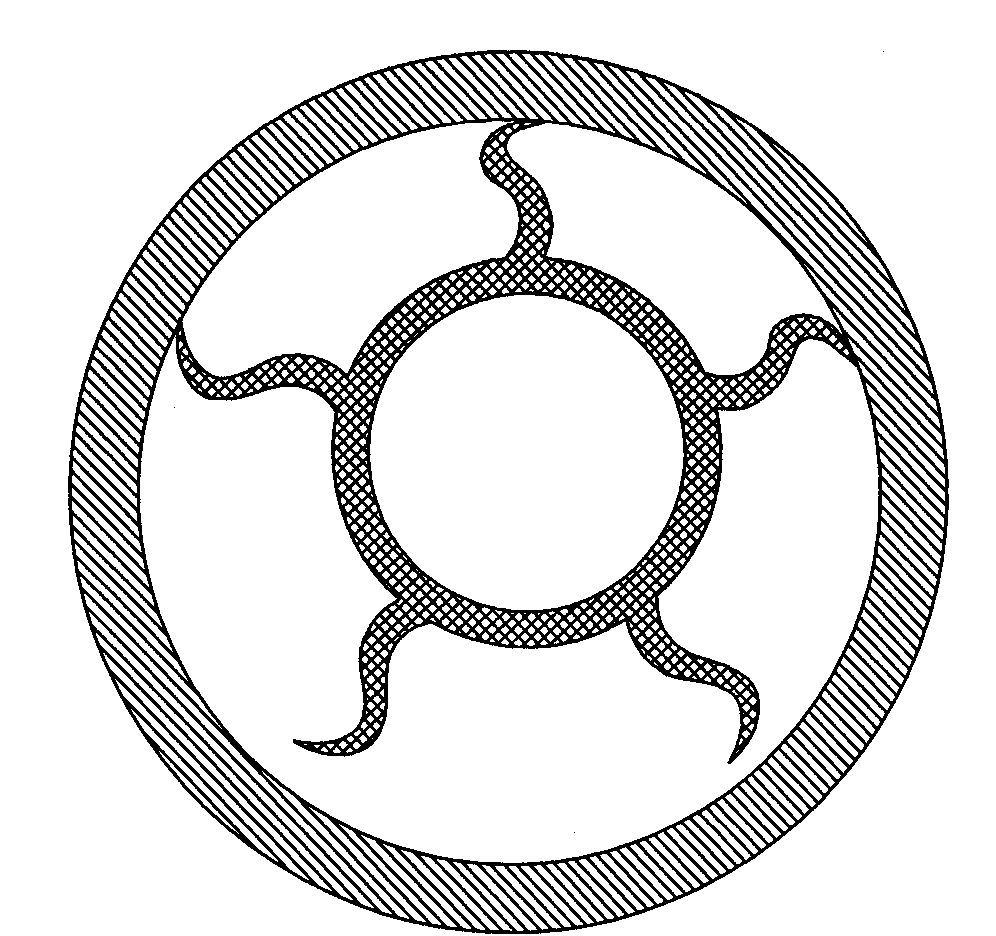

[0025] Embodiment 2: In the cross-section of the inner tube body 1, the line connecting the tip apex of the elastic support blade 3 and the center of the ring where the inner tube body 1 is located passes through the outer wall surface of the inner tube body 1 on the outside of the elastic support blade 3 ,Such as Figure 5 .

[0026] The section of the rigid support blade 2 is a solid rectangle.

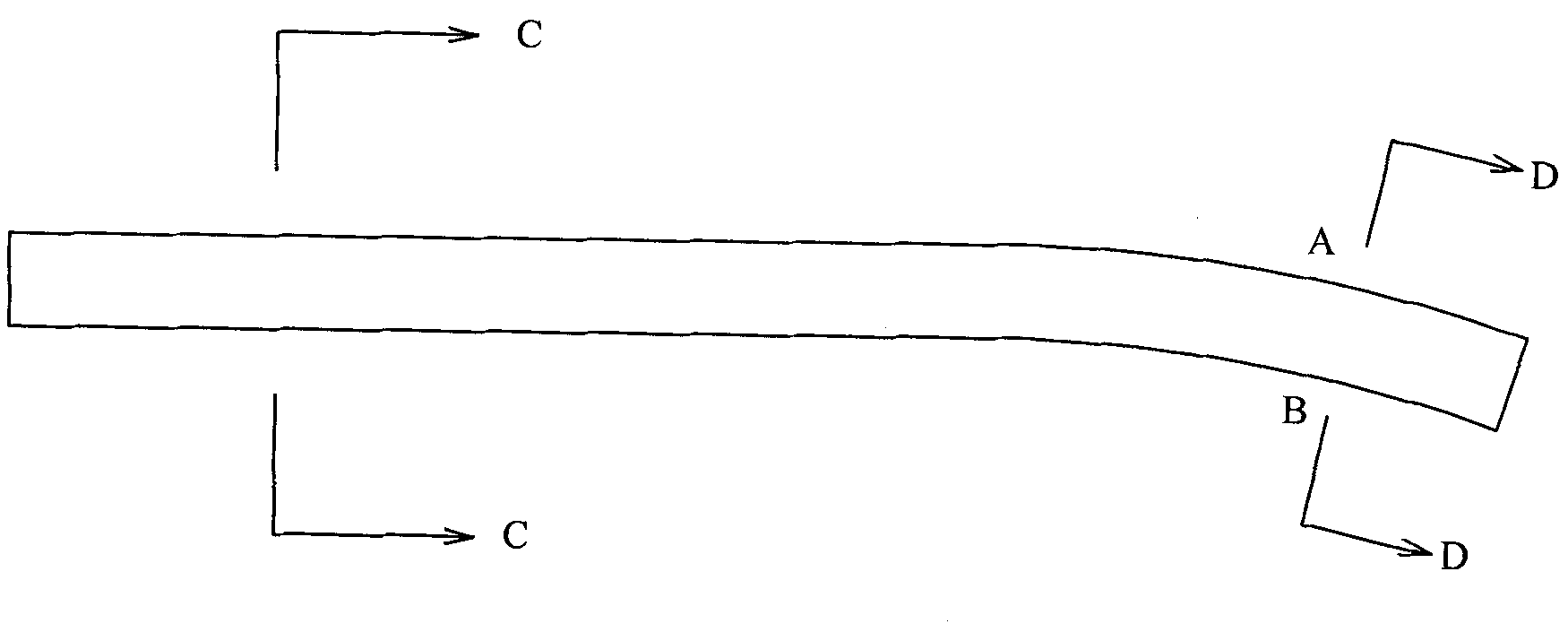

[0027] The thickness of the rigid support blade 2 from the root to the blade tip is consistent to increase the mechanical strength of the blade itself. The direction of the action and reaction force between the rigid support blade 2 and the metal outer sleeve is radially consistent, without tangential component force, and is not easy to bend and deform . At the outer arc part of the bending of the metal outer sleeve, that is, the A position, the radial reaction force on the rigid support blade 2 formed by the rebound stress after the bending of the support tube presses the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com