Pilot-operated electrical feedback proportional direction valve

A proportional directional valve, electrical feedback technology, applied in the direction of fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problems of poor steady-state and dynamic performance, low sensitivity, low pressure gain and flow gain, etc. Achieve high reliability, high sensitivity and high dynamic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

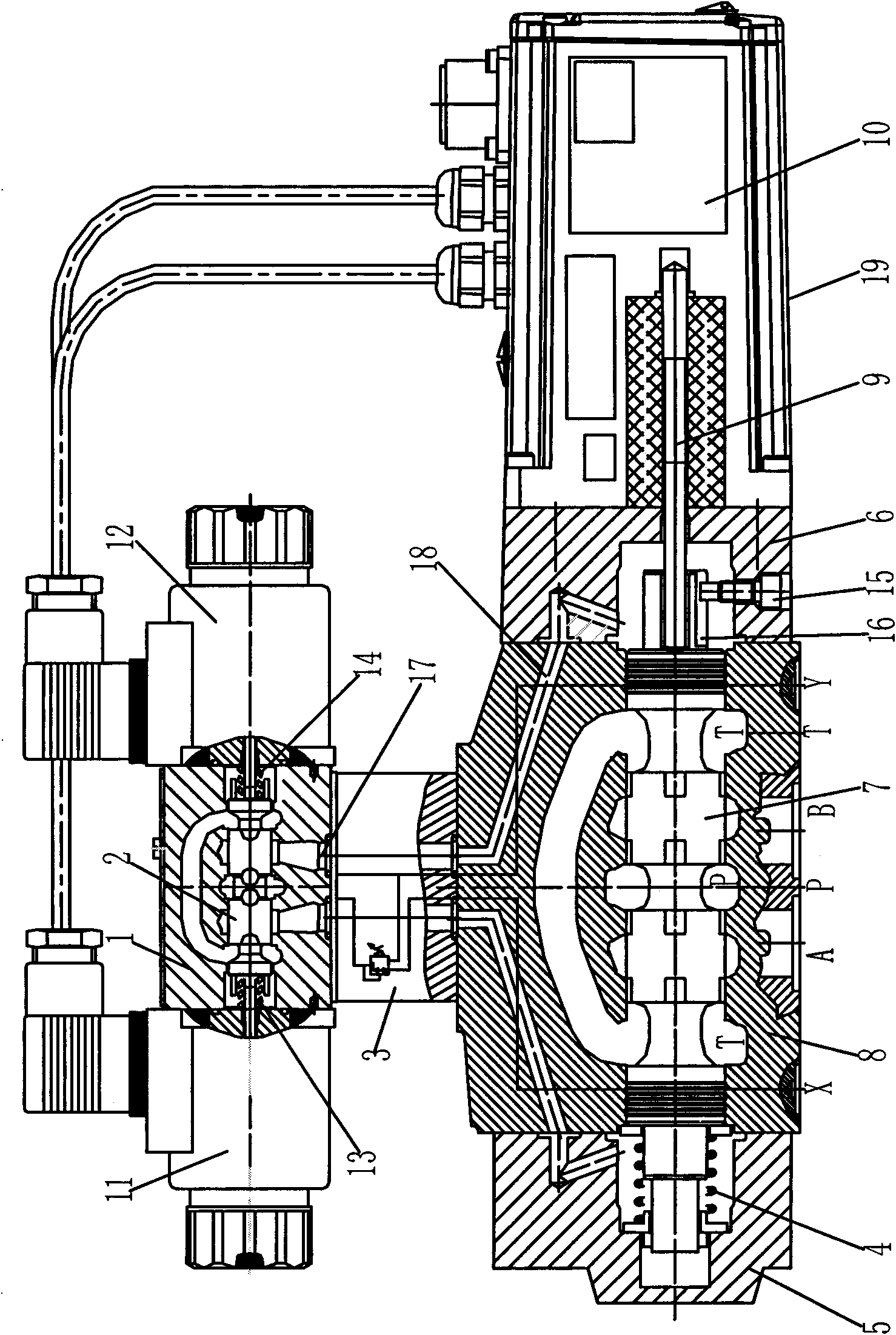

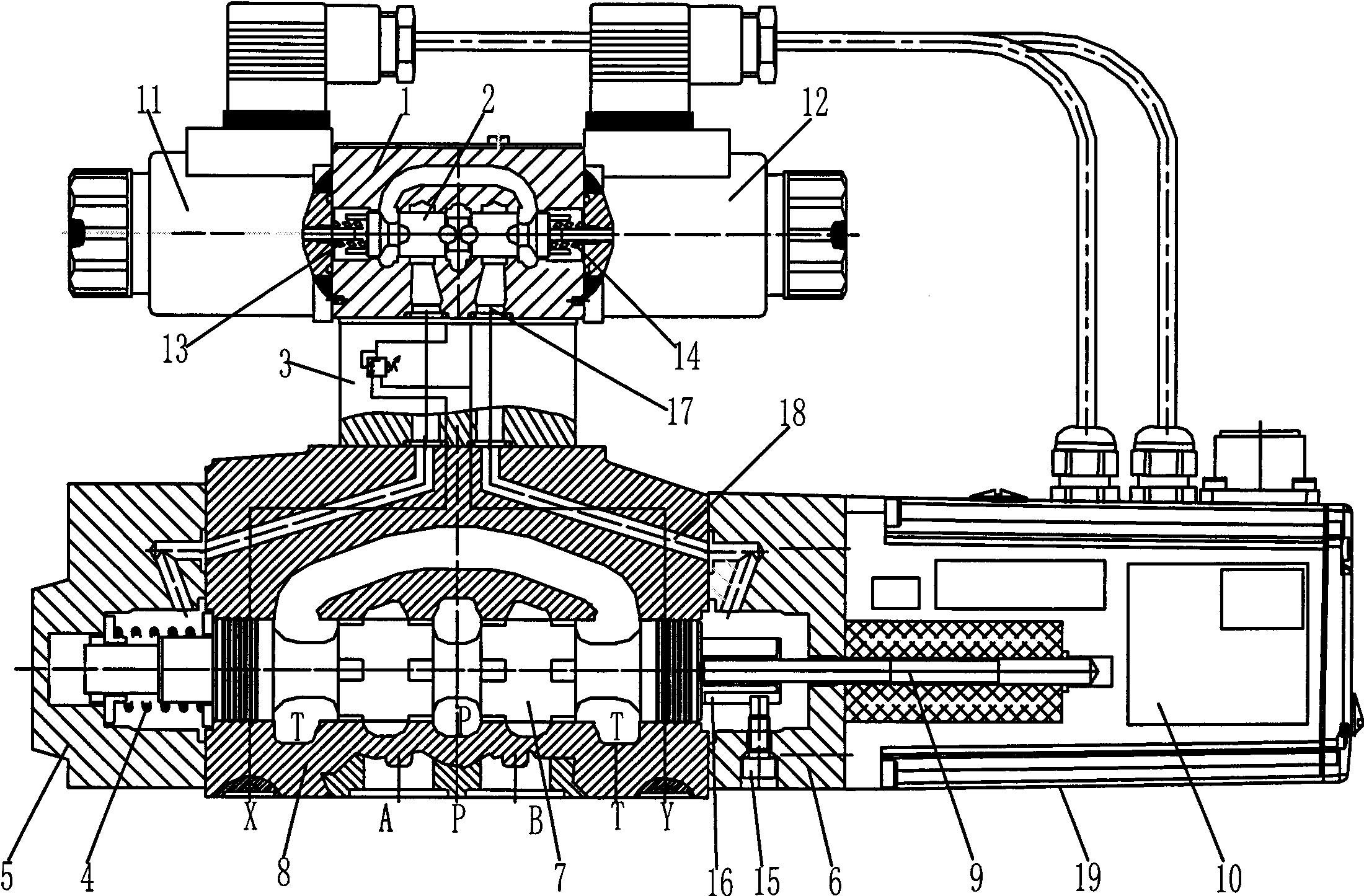

[0013] Such as figure 1 As shown, the pilot-operated electric feedback proportional directional valve of the present invention includes a pilot stage and a main stage, a decompression backing plate 3 is provided between the pilot stage and the main stage, and the pilot stage includes a stroke-controlled proportional directional valve, a proportional electromagnet A11 and proportional electromagnet B12. One end of the stroke control proportional directional valve is connected to the proportional electromagnet A11, and the other end is connected to the proportional electromagnet B12. The stroke control proportional directional valve includes pilot valve body 1, pilot spool 2, spring A13 and spring B 14: The lower part of the pilot valve body 1 is provided with a plurality of oil ports 17, the pilot valve core 2 communicates with each oil port 17 through the oil passage 18, and each oil port 17 communicates with the main stage oil passage 18. The main stage includes the main valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com