Paper machine tensioning

A technology for paper machines and net blankets, applied in the field of net blankets, can solve a large number of separate processes and other problems, achieve the effect of improving connections and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

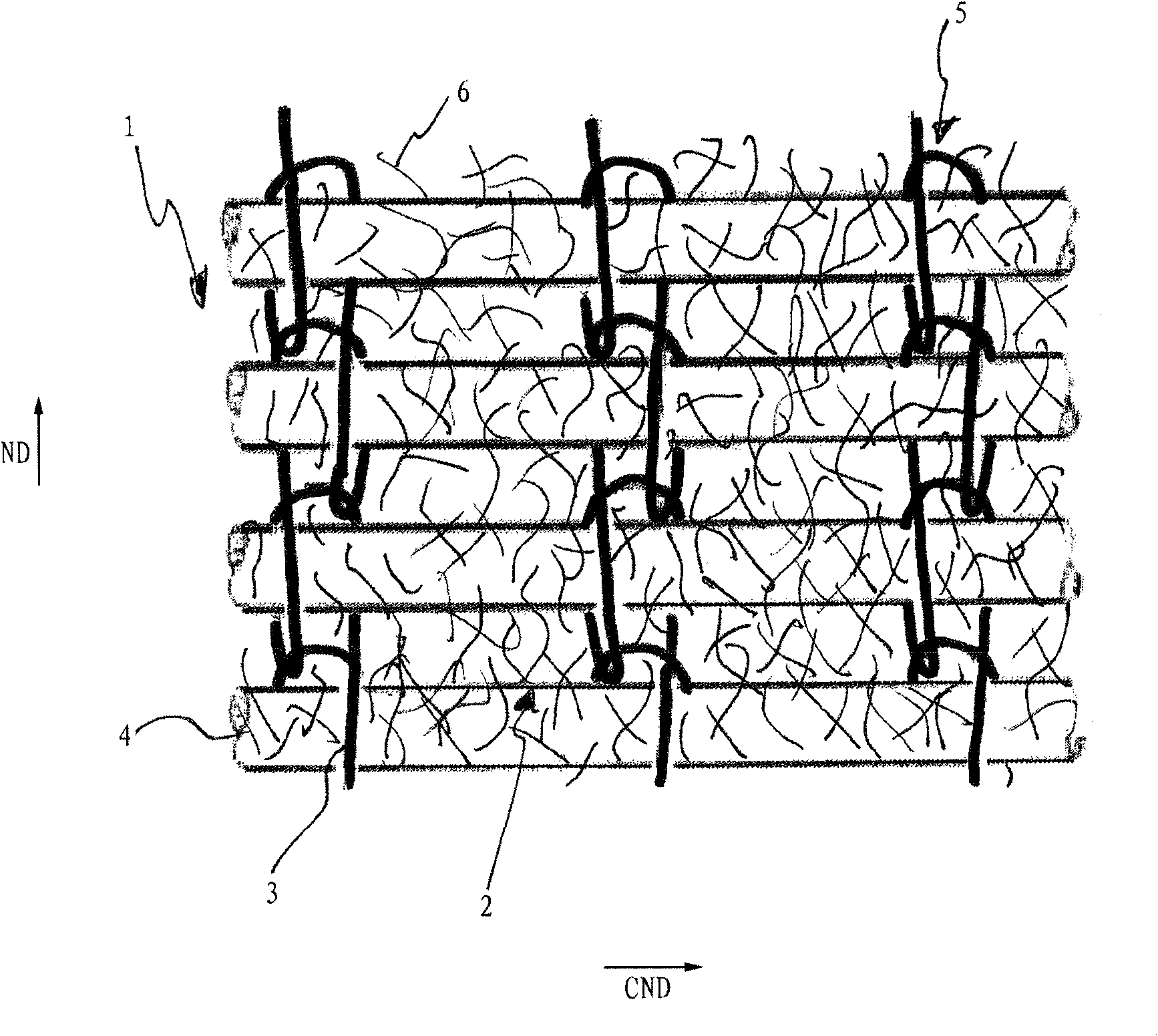

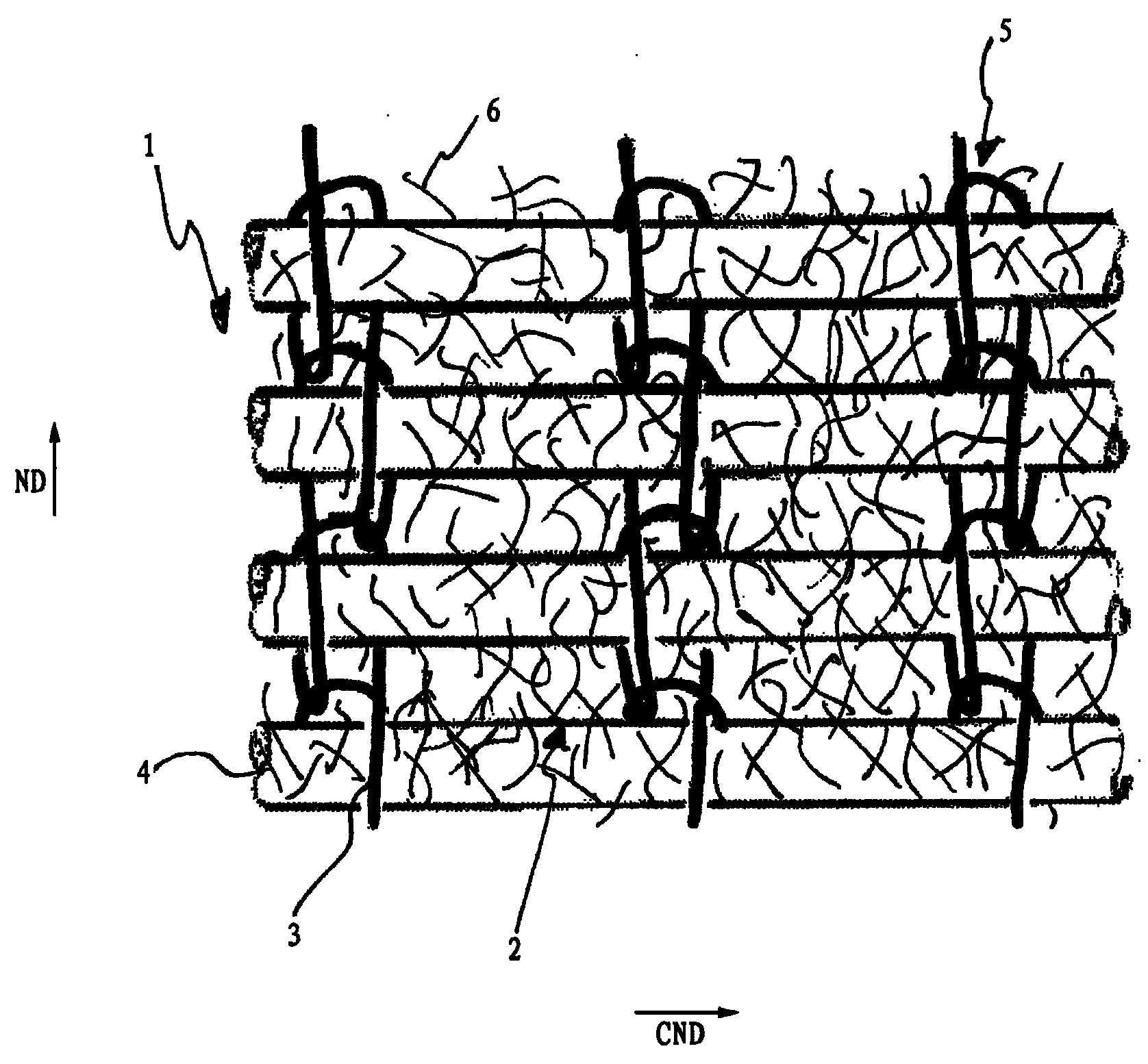

[0037] figure 1 A warp-knitted structure 1 with an intermediate layer 2 attached is shown. The warp knitted structure 1 is composed of sewing threads 3 and reinforcing threads 4 which run parallel to one another along their length, wherein the reinforcing threads 4 have a greater bending stiffness than the sewing threads 3 . These sewing threads 3 form a mesh into which reinforcing threads 4 are woven in order to form the warp knitted structure 1 . In the present case, the sewing threads 3 form rows 5 of meshes arranged parallel to one another and extending substantially perpendicularly to the reinforcing threads 4 into which the reinforcing threads 4 are woven.

[0038] According to the invention, an intermediate layer 2 is provided on the warp knitted structure 1 , which is connected by sewing threads 3 with reinforcing threads 4 .

[0039] The intermediate layer 2 is currently composed of a spunbond nonwoven, which in turn consists of polyurethane fibers 6 . The mass per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com