Nano-glass heat insulation paint and preparation method thereof

A heat-insulating coating and nano-glass technology, applied in the field of coatings, can solve the problems of poor heat-insulating effect of water-based glass heat-insulating coatings, achieve high visible light transmittance, simple preparation method, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

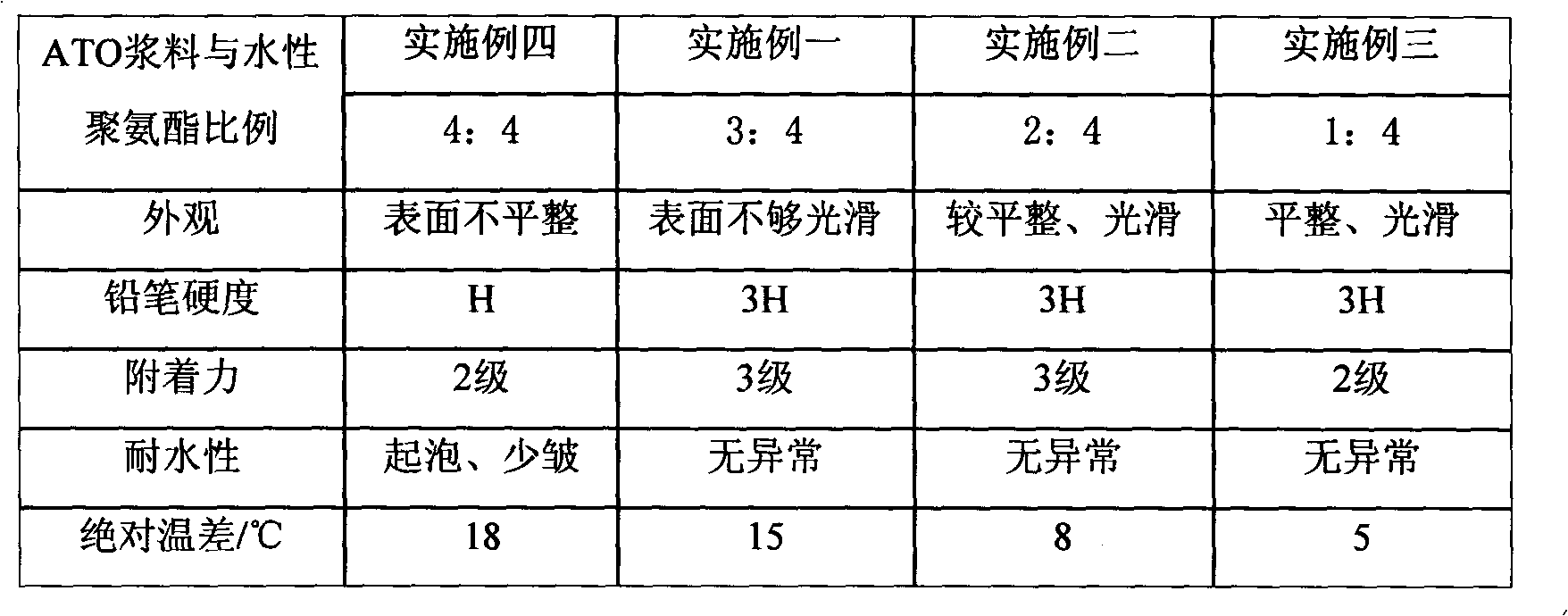

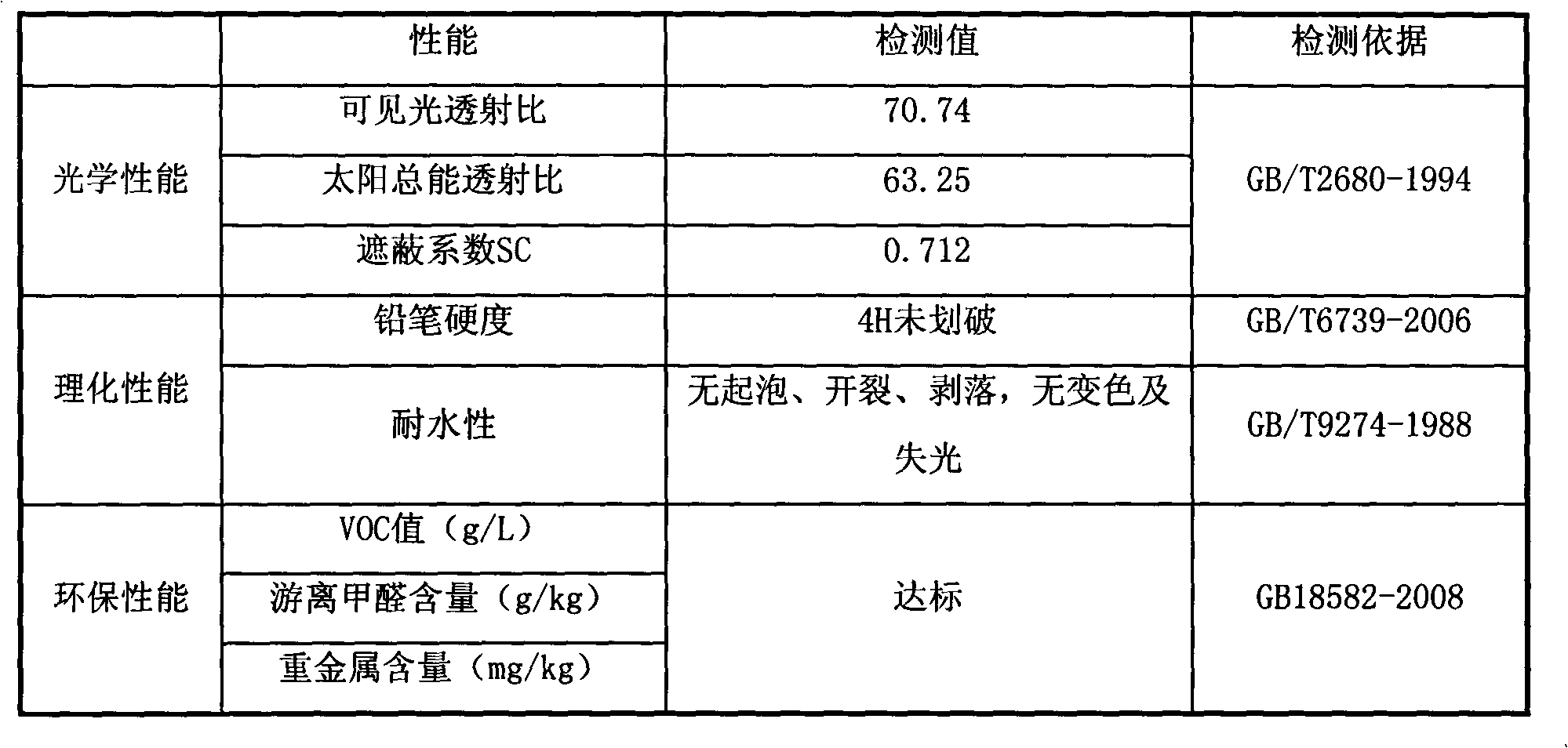

Embodiment 1

[0025] This embodiment provides a nano-glass heat-insulating coating, which can be painted on glass to form a film, and has the function of blocking heat and ultraviolet rays. The heat-insulating coating includes: polyol A component and curing agent B component;

[0026] Among them, the polyol A component is mixed with nano-antimony tin oxide slurry and water-based polyurethane in a mass ratio of 4:1 to 1:1, dispersed at a speed of 800r / min for 30 minutes, and then added to the polyol A component Divide 1.7-15% of the total mass of curing agent B component additives, and disperse at a speed of 400r / min-450r / min for 60 minutes to obtain polyol A component; wherein, the additives include: adhesion promotion agents, wetting agents, leveling agents, defoamers and thickeners;

[0027] The nano antimony tin oxide slurry used in the polyol A component is based on nano antimony tin oxide, a mixture of water and absolute ethanol formed by mixing 1:1 by volume, and a polymer anion dispe...

Embodiment 2

[0041] This embodiment provides a nano-glass heat-insulating coating, which can be painted on glass to form a film, and has the function of blocking heat and ultraviolet rays. The heat-insulating coating includes: polyol A component and curing agent B component;

[0042] Each component and consumption are basically the same as those given in Example 1. The difference is that the ratio of the water-based polyurethane used in the polyol A component and the nano-ATO slurry is 4: 2 by mass ratio, and water can be added to the water-based polyurethane simultaneously. For dilution, the raw materials are taken according to the mass ratio of water-based polyurethane, nano-ATO slurry, and water in a ratio of 4:2:2. The preparation method of the polyol A component is the same as in the above-mentioned embodiment 1, and will not be repeated here.

[0043] Prepare the nano-glass heat-insulating coating, and after the obtained coating is coated with the same method, the relevant properties ...

Embodiment 3

[0045] This embodiment provides a nano-glass heat-insulating coating, which can be painted on glass to form a film, and has the function of blocking heat and ultraviolet rays. The heat-insulating coating includes: polyol A component and curing agent B component;

[0046] Each component and consumption are basically the same as those given in Example 1. The difference is that the ratio of the water-based polyurethane used in the polyol A component and the nano-ATO slurry is 4: 1 by mass ratio, and water can be added to the water-based polyurethane simultaneously. For dilution, the raw materials are taken according to the mass ratio of water-based polyurethane, nano-ATO slurry, and water at a ratio of 4:1:3. The preparation method of the polyol A component is the same as in the above-mentioned embodiment 1, and will not be repeated here.

[0047] Prepare the nano-glass heat-insulating coating, and after the obtained coating is coated with the same method, the relevant properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com